-

+86 156 6587 0861

-

Shunhua Road, Jinan City, Shandong

Laser Cleaner & Laser Cleaning Machines Factory!

What Is Laser Cleaning

Cost-Effective Laser Cleaning

Health & Environmental Impact

Benefits of Laser Cleaning Machines

Material Versatility

Maintenance Optimization

Safety and Sustainability

Long-Term Cost Efficiency

Superior Cleaning Performance

Minimal Environmental Impact

Pulse Laser Cleaning Machines Factory in Jinan, Shandong

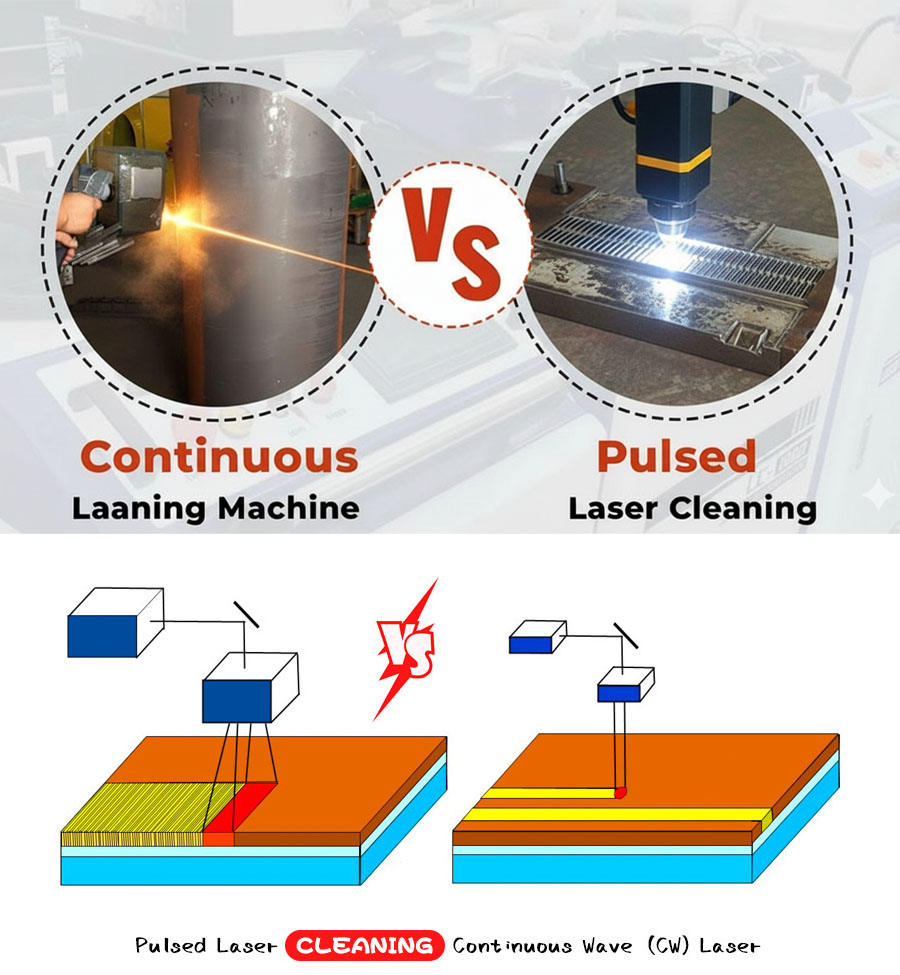

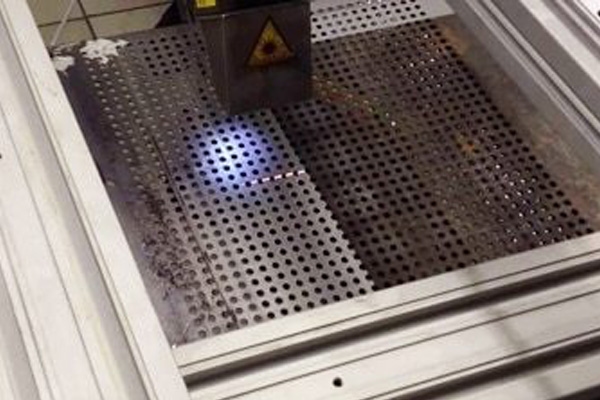

Pulse VS Continuous Laser Cleaning Machine

Pulse laser cleaning machines are ideal when your parts demand high surface quality—precision machining, electronics, thin coatings. They shine for small-area cleaning: the trade-off is modest efficiency, but the accuracy and minimal heat impact often justify it.

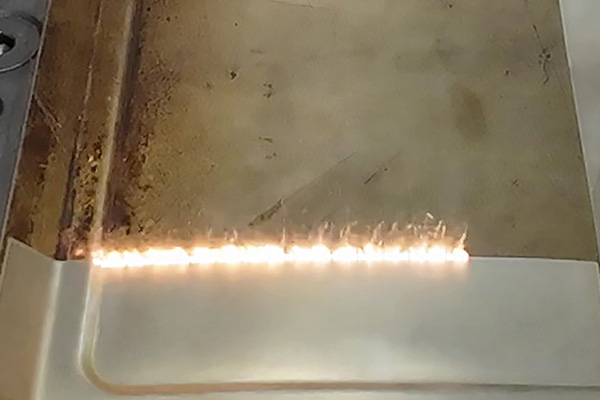

Continuous laser cleaning machines suit bulk, rugged jobs—rust removal, large equipment, factory frames. Their strength is efficiency over area, though with higher thermal demand and risk on delicate parts. According to Laser Focus World, surfaces cleaned by CW lasers often appear darker and rougher than those cleaned by pulsed systems under the same power.

Laser Focus World

In practice: if you clean molds, tools, sensitive metals—go pulse. If you strip heavy coatings from steel or structural surfaces with tolerance for heat, CW often becomes your go-to.

Pulse Laser Cleaning Machines Factory in Jinan, Shandong

Portable Handheld Laser Cleaner For Sale At Cost Price

1000W 1500W 2000W 3000W Continuous Laser Cleaning Machines

Wholesale Price High Efficiency 3KW Laser Cleaning Machines

Factory Direct 1500-2000W Handheld Laser Cleaner Machines

500 W1000 W Nanosecond Pulsed Laser Cleaner Manufacturer

100 W 200 W 300 W Air-Cooled Pulse Laser Cleaning Machines

Custom 300 W Backpack Rust-Removal Laser Cleaner Wholesaler

300 W / 500 W Suitcase Pulse Laser Cleaning Machines Factory

Why Choose Us?

15+ years

100% quality assurance

3000+ projects

24/7 support

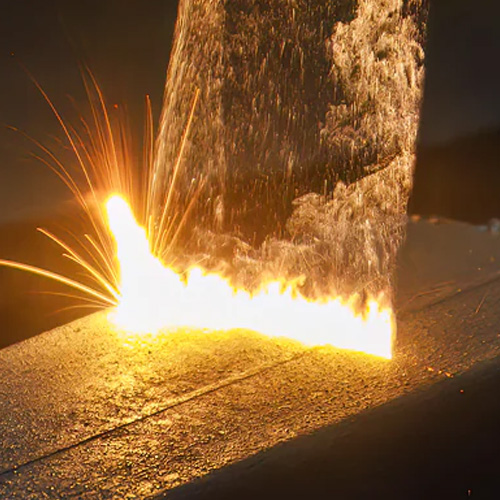

Rust and Corrosion Removal

Effectively cleaning rust, oxidation, and other corrosive layers from various metal surfaces and components without abrasive damage.

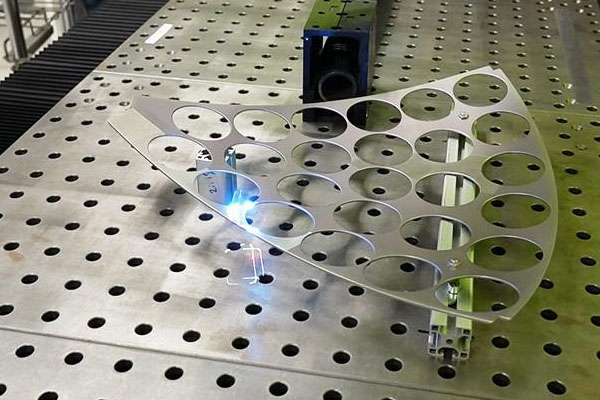

Surface Preparation

Pre-treating metal surfaces before welding, brazing, painting, or adhesive bonding to enhance adhesion and ensure high-quality finishes and strong bonds.

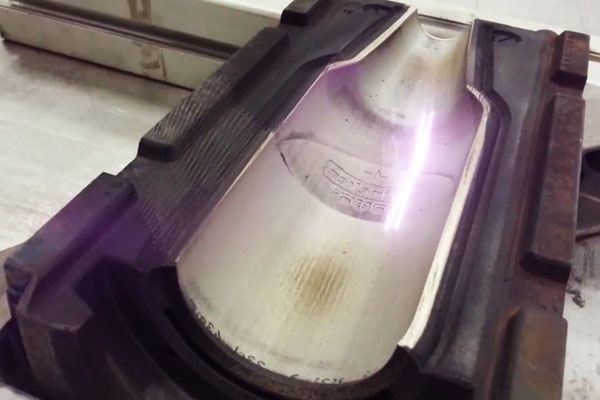

Mold Cleaning

Efficiently removing residues such as release agents, rubber, silicone oil, and other production contaminants from industrial molds, including tire molds.

Coating and Paint Removal

Stripping off various coatings, including paint, e-coat, ceramic coatings, and other protective or decorative layers, from substrates without causing damage.

Nuclear Decontamination

A precise and safe method for removing radioactive contaminants from nuclear materials, equipment, and facilities, minimizing waste.

Micro-electronics Cleaning

Providing high-precision, non-contact cleaning for delicate components and circuit boards in the electronics industry, essential for quality and performance.

Oil and Grease Removal

Ablating oils, greases, and other organic contaminants from industrial parts and surfaces, often for maintenance or further processing.

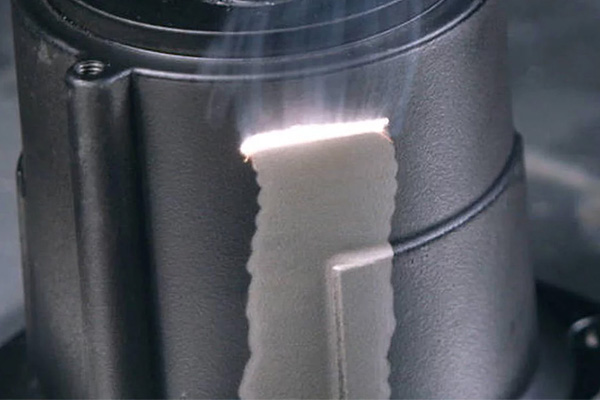

Welding Seam Treatment

Cleaning welding seams to remove spatter, oxides, and other residues, improving the quality and appearance of welded joints.

Maintenance of Large Structures

Cleaning and preparing surfaces of large infrastructures such as tanks, bridges, wind turbine towers, and pipelines for maintenance or repair.

Automotive & Aerospace Maintenance

Used for surface preparation for bonding, removing paint defects, cleaning engine components, and restoring surfaces of vehicles and aircraft.

Railroad & Maritime Cleaning

Cleaning rail tracks to improve signal conductivity and remove contaminants, as well as maintaining ships and other marine vessels by removing rust and coatings.

Art and Heritage Restoration

Gently cleaning delicate historical artifacts, statues, monuments, and architectural elements made of stone, granite, marble, and other materials.

Jewelry and Antique Restoration

Precisely removing tarnish, dirt, and oxides from intricate jewelry pieces, coins, and antiques without causing wear or damage.

Medical Device Sterilization

Providing a high-precision, residue-free method for cleaning and sterilizing critical medical equipment and instruments. High-efficient!

Food and Beverage Equipment Cleaning

Cleaning and sanitizing surfaces and equipment in food processing and packaging facilities, ensuring hygiene and product safety.

Pulse Laser Cleaning Machines Factory in Jinan, Shandong

Laser Cleaning Machine Cost: Complete Price Analysis 2026

In 2025, Laser cleaning has become one of the most popular and demanding technologies in the world.

Advantages of Using Laser Cleaning Machines

More and more people like to use laser cleaning machine remove painting, rust, etc for their project. This technology offers a modern approach to removing contaminants without the need for harsh chemicals or abrasive methods. In this article, we’ll explore the advantages of using laser cleaning machines, particularly focusing on their effectiveness and versatility. What is a Laser Cleaning Machine? A laser cleaning machine adopt laser beams to remove unwanted materials from surfaces. This process is known as laser ablation, where the laser’s energy breaks down and vaporizes contaminants without damaging the underlying material. This precise method of cleaning is suitable for a wide range of applications, from industrial uses to delicate restoration projects. How Does It Work? The working principle of a laser cleaning machine is to use high-energy laser beams to irradiate the surface of…

Pulse Laser Cleaning Machine VS Continuous Laser Cleaning Machine

In this article, I don’t just want you to memorize pros and cons. I want you to feel the decision. To sense when a pulsed cleaner will save your parts, and when a continuous one will speed you through piles.