How Much Does Laser Away Actually Cost?

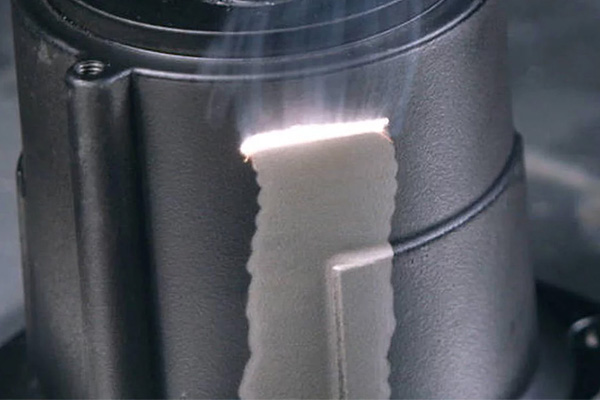

Rust never waits. The longer corrosion remains on steel, machinery, molds, or structural components, the deeper it penetrates—and the more expensive remediation becomes. Traditional sandblasting damages surfaces, chemical pickling creates environmental liabilities, and manual grinding consumes labor hours while reducing dimensional accuracy. Many industrial managers hear about “laser rust removal” and ask the same question: how much does laser away actually cost? Without clarity, companies hesitate—risking higher long-term repair costs, compliance issues, and productivity loss. The solution is not guessing—it is understanding the full economic structure behind laser cleaning investment, including capital cost, operating cost, depreciation, ROI, and lifecycle savings.

Laser rust removal cost typically ranges from 6,000 to120,000+ depending on laser power (100W–6000W), pulse vs. continuous wave configuration, automation level, and brand quality. Entry-level portable pulsed fiber laser cleaners start around 6,000–12,000. Industrial 1000W–2000W systems range between 18,000–45,000. High-power 3000W–6000W continuous systems for heavy corrosion removal can exceed 60,000–120,000. Actual cost must also include consumables, electricity, labor savings, and return on investment over 3–5 years.

Before making a purchasing decision, it is essential to evaluate not only the purchase price but the total cost of ownership, performance capability, and payback period. As a professional manufacturer in the laser cleaning industry, I will break down the cost structure in depth, supported by real data, engineering parameters, and industrial case studies.

Understanding the Core Cost Drivers of Laser Rust Removal

Laser rust removal systems are primarily fiber laser–based cleaning machines. The pricing difference between models is driven by five major technical variables:

- Laser Power Output (Wattage)

- Laser Type (Pulsed vs Continuous Wave)

- Beam Quality & Pulse Energy (mJ range)

- Cooling System (Air-cooled vs Water-cooled)

- Automation & Integration Capabilities

Power Level vs Cost Comparison Table

| Laser Power | Typical Application | Cleaning Speed | Machine Price Range | Ideal Industry |

|---|---|---|---|---|

| 100W | Light rust, paint removal | 1–2 m²/hour | $6,000–$9,000 | Small workshops |

| 200W | Surface oxidation | 2–4 m²/hour | $8,000–$14,000 | Auto repair |

| 300W | Medium rust | 3–6 m²/hour | $10,000–$18,000 | Fabrication shops |

| 500W | Heavy rust | 5–8 m²/hour | $15,000–$25,000 | Ship parts |

| 1000W | Industrial rust | 8–15 m²/hour | $18,000–$35,000 | Manufacturing plants |

| 2000W | Thick corrosion | 15–25 m²/hour | $30,000–$60,000 | Shipyards |

| 3000W–6000W | Scale & mill oxide | 25–60 m²/hour | $60,000–$120,000+ | Heavy industry |

Higher wattage directly increases cleaning efficiency and depth capability. However, many small businesses overinvest in power that they do not fully utilize.

Pulsed vs Continuous Laser Cost Structure

Pulsed fiber lasers deliver high peak power (2mJ–15mJ pulse energy), making them ideal for precision rust removal without damaging substrate metal. Continuous wave (CW) lasers provide stable high thermal output suitable for thick corrosion and large-scale cleaning.

| Parameter | Pulsed Fiber Laser | Continuous Wave Laser |

|---|---|---|

| Surface Damage Risk | Very Low | Moderate |

| Precision | High | Medium |

| Thick Rust Removal | Moderate | Excellent |

| Average Cost | Slightly Higher per Watt | Lower per Watt |

| Maintenance | Low | Low |

Most precision industries prefer pulsed systems, while shipbuilding and heavy machinery sectors choose CW systems.

Total Cost of Ownership (TCO) Over 5 Years

Many buyers focus solely on upfront purchase price. However, true evaluation requires TCO analysis.

5-Year Cost Comparison: Laser vs Sandblasting

| Cost Element | Laser Cleaning | Sandblasting |

|---|---|---|

| Equipment Investment | $25,000 | $8,000 |

| Media Consumption | $0 | $18,000 |

| Labor (2 operators) | $60,000 | $110,000 |

| Surface Damage Repairs | Minimal | $15,000 |

| Waste Disposal | Minimal | $22,000 |

| Total 5-Year Cost | ~$85,000 | ~$173,000 |

Laser cleaning reduces long-term operational costs dramatically despite higher upfront investment.

Electricity Consumption Analysis

Fiber laser cleaning machines are highly energy-efficient. For example:

• 1000W laser consumes approximately 3–4 kW total system power

• Operating cost per hour ≈ 0.40–0.80 (depending on local electricity rates)

Compared to compressed-air blasting systems requiring large air compressors (often 15–30 kW), laser systems offer substantial energy savings.

Industrial ROI Case Study

A metal fabrication plant invested in a 1000W pulsed laser cleaner at 28,000.

• Labor reduced from 2 operators to 1

• Media cost eliminated (5,000/year)

• Surface rework reduced by 60%

• Payback period: 14 months

• 5-year profit impact: $120,000+

This illustrates why many companies transition to laser rust removal technology.

Portable vs Automated Laser Cleaning Systems

Portable handheld machines are more affordable but require manual operation. Automated robotic laser cleaning systems integrate CNC control and scanning heads.

| Type | Cost Range | Use Case |

|---|---|---|

| Portable | $6,000–$30,000 | Flexible on-site jobs |

| Cabinet Type | $20,000–$50,000 | Controlled factory use |

| Robotic System | $80,000–$250,000 | High-volume automation |

Automation increases capital cost but reduces labor and increases repeatability.

Hidden Costs Buyers Should Evaluate

- Replacement protective lenses

- Cooling system maintenance

- Operator training

- Shipping & customs fees

- Warranty coverage

High-quality fiber sources (Raycus, JPT, IPG) significantly influence price and durability.

Performance vs Price Optimization Strategy

Instead of purchasing the highest wattage machine, companies should evaluate:

• Rust thickness (micron measurement)

• Daily cleaning area requirement

• Material type (carbon steel, aluminum, stainless steel)

• Required surface finish

Overpowered systems increase investment without improving ROI.

Market Price Trends

Over the past five years, fiber laser prices have decreased approximately 20–35% due to manufacturing scale in Asia and improved diode technology. However, high-end systems with advanced scanning heads and safety enclosures remain premium products.

Safety & Regulatory Cost Factors

Laser cleaning machines must comply with:

• CE certification

• FDA (for US market)

• Laser Class IV safety requirements

• Protective goggles & shielding

Safety integration slightly increases upfront investment but prevents legal risks.

Comparing Service-Based Laser Cleaning Cost

If outsourcing rust removal services:

• Small component: 100–300 per piece

• Industrial equipment: 8–25 per square meter

• Ship hull section: 20–40 per m²

For frequent usage, purchasing equipment becomes financially advantageous within 1–2 years.

Cost Breakdown Example: 1000W Laser System

| Component | Cost Share |

|---|---|

| Fiber Source | 40% |

| Control System | 15% |

| Cooling Unit | 10% |

| Mechanical Structure | 15% |

| Scanner & Optics | 10% |

| Assembly & Testing | 10% |

Understanding internal cost structure helps buyers negotiate realistically.

When Does Laser Cleaning Not Make Financial Sense?

• Very small cleaning volumes

• One-time rust removal projects

• Extremely thick mill scale requiring mechanical pre-treatment

In such cases, rental or outsourcing may be better options.

Future Cost Outlook

As semiconductor diode efficiency improves and modular laser systems scale production, prices are expected to decline further while power density increases.

Laser cleaning technology is transitioning from niche to mainstream industrial maintenance solution.

Laser rust removal cost varies widely—from entry-level portable systems around 6,000 to industrial high-power automated systems exceeding120,000. However, the true cost must be evaluated across lifespan, labor reduction, consumable elimination, energy efficiency, and productivity gains. In most medium-to-high volume industrial environments, laser cleaning delivers payback within 1–2 years and significant long-term savings.

Let’s Talk About the Right Solution for Your Application

Choosing the right laser cleaning system is not about buying the most expensive machine—it is about matching power, efficiency, and budget to your real production needs. At BOGONG Machinery, we help clients calculate ROI precisely, select optimal configurations, and ensure long-term reliability.

If you are considering investing in laser rust removal equipment, reach out to our engineering team. We will evaluate your material, rust condition, and production targets to recommend the most cost-effective solution tailored to your business.

BOGONG Machinery – Industrial Laser Cleaning Experts

We look forward to supporting your next upgrade in surface treatment technology.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com