Why Are Laser Cleaners So Expensive?

Rust, paint, oxide layers, and surface contamination cost industries millions every year in maintenance downtime, labor inefficiency, and abrasive damage. Traditional methods—sandblasting, chemical cleaning, mechanical grinding—introduce hidden costs such as consumables, environmental compliance, substrate damage, and safety risks. When companies first encounter laser cleaning machines and see price tags ranging from 6,000 to over150,000, the reaction is immediate: “Why is this so expensive?” The concern is understandable. However, the perceived high cost is often misunderstood because buyers focus only on purchase price, not on engineering complexity, performance capability, and total lifecycle economics.

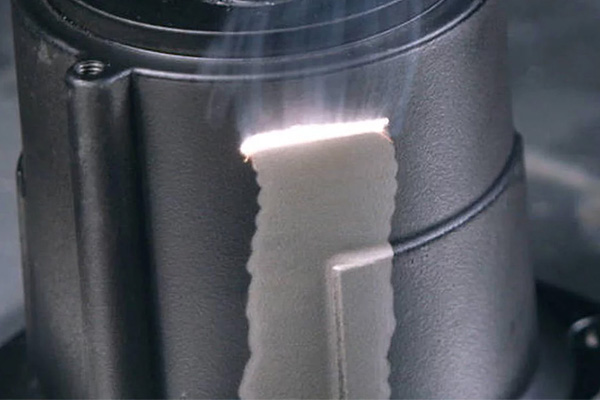

Laser cleaners are expensive because they integrate high-power precision fiber laser sources, advanced optical systems, high-speed control electronics, industrial cooling units, safety-compliant enclosures, and specialized beam delivery systems into a single synchronized platform. Unlike traditional cleaning tools, laser cleaners are precision photonic systems designed to deliver controlled ablation energy at micron-level accuracy without damaging substrates. The cost reflects advanced manufacturing, safety compliance, component quality, reliability engineering, and long-term performance stability.

If you are evaluating whether a laser cleaner is overpriced—or fairly valued—you need a technical breakdown of what you are actually paying for. Let’s analyze this systematically from an engineering and industrial economics perspective.

The Core Cost Driver: The Fiber Laser Source

At the heart of every laser cleaning machine is the fiber laser source. This is not a simple light emitter. It is a highly engineered photonic system consisting of:

- Pump diodes

- Rare-earth doped fiber (usually ytterbium-doped fiber)

- Optical resonator cavity

- Power amplification modules

- Beam shaping optics

The laser source alone can account for 40–60% of the total machine cost.

Typical Fiber Laser Cost vs Power Level

| Laser Power | Type | Approx. Laser Source Cost | Typical Application |

|---|---|---|---|

| 100W | Pulsed Fiber | $2,000–$4,000 | Light rust, paint removal |

| 300W | Pulsed Fiber | $5,000–$8,000 | Industrial oxide cleaning |

| 1000W | Pulsed Fiber | $12,000–$20,000 | Heavy rust removal |

| 3000W+ | CW Fiber | $25,000–$60,000 | Thick coating stripping |

Higher power requires:

- More pump diodes

- Higher thermal management

- Enhanced power stability circuits

- Industrial-grade fiber coupling

The engineering precision required to maintain beam quality (M² value) under high power output significantly increases production cost.

Precision Optics and Galvanometer Scanning Systems

Laser cleaning machines rely on high-speed galvanometer scanners to direct the beam across surfaces. These scanners:

- Operate at 10,000+ mm/s

- Require micron-level angular precision

- Must resist thermal drift

Inferior scanning systems cause:

- Uneven cleaning

- Overburning

- Reduced lifespan

Premium galvanometer systems alone can cost 2,000–6,000 depending on performance specifications.

Industrial Cooling Systems

Laser systems generate substantial heat. A stable temperature range is essential for beam consistency and diode longevity.

Two common cooling methods:

| Cooling Type | Cost Range | Used For |

|---|---|---|

| Air Cooling | Lower cost | ≤300W systems |

| Industrial Water Chiller | $1,000–$4,000 | 500W+ systems |

Water chillers must maintain ±1°C temperature control. Poor cooling reduces diode lifespan dramatically.

Advanced Control Electronics & Software

Modern laser cleaners integrate:

- Pulse width modulation control

- Frequency tuning (20kHz–200kHz typical)

- Touchscreen HMI interfaces

- Safety interlock systems

Precision pulse control determines:

- Energy density

- Ablation depth

- Substrate safety

The software development and hardware integration significantly increase system complexity.

Safety Engineering & Compliance

Laser cleaning systems must comply with international standards:

- IEC 60825 (Laser Safety)

- CE certification

- FDA standards (USA)

- ISO quality systems

Safety features include:

- Emergency stop circuits

- Beam shielding

- Key switch protection

- Protective enclosures

Compliance certification and testing add both cost and engineering overhead.

Mechanical Structure & Industrial Design

Unlike consumer devices, laser cleaners are built for industrial environments:

- Vibration-resistant cabinets

- EMI shielding

- High-grade aluminum or steel housings

- IP-rated enclosures

Industrial reliability increases cost but ensures multi-year durability.

R&D and Intellectual Property

Laser cleaning is an evolving technology. Manufacturers invest heavily in:

- Beam optimization research

- Ablation efficiency improvement

- Energy consumption reduction

- Software interface innovation

R&D costs are embedded in final pricing.

Total Cost of Ownership Comparison

Although purchase price appears high, operational economics tell a different story.

3-Year Cleaning Cost Comparison

| Method | Equipment Cost | Consumables | Labor | Environmental Cost | Total 3-Year Cost |

|---|---|---|---|---|---|

| Sandblasting | $8,000 | $15,000 | High | High | $45,000+ |

| Chemical Cleaning | $5,000 | $20,000 | Medium | High | $50,000+ |

| Laser Cleaning | $25,000 | $0 | Low | Minimal | $28,000 |

Laser cleaning often delivers ROI within 12–24 months in industrial applications.

Market Positioning & Industry Maturity

Laser cleaning technology is still maturing. Production volumes are lower than traditional tools, which limits economies of scale.

However, costs have decreased significantly over the past decade:

| Year | Average 1000W Laser Cleaner Price |

|---|---|

| 2015 | $80,000 |

| 2020 | $45,000 |

| 2025 | $18,000–$30,000 |

Prices continue to decline as manufacturing improves.

Pulsed vs Continuous Wave Cost Differences

Pulsed lasers are generally more expensive due to:

- Complex pulse control electronics

- Higher peak power generation

- Advanced fiber modulation systems

| Type | Cost | Advantage |

|---|---|---|

| Pulsed | Higher | Substrate protection |

| Continuous Wave | Lower | High-speed stripping |

Application requirements influence cost justification.

Hidden Engineering Complexity

Laser cleaning requires precise energy density control measured in J/cm².

Too low:

- Ineffective cleaning

Too high:

- Substrate melting

Maintaining this balance requires:

- Stable beam profile

- High repetition rate stability

- Precision focusing lenses

This level of engineering is not comparable to mechanical tools.

Why Cheap Laser Cleaners Are Risky

Low-cost units often compromise:

- Diode quality

- Beam uniformity

- Safety standards

- Cooling stability

Short lifespan or inconsistent performance results in higher long-term costs.

Is Laser Cleaning Overpriced?

No. It is a capital investment in precision photonic technology.

The cost reflects:

- Advanced fiber optics

- High-power electronics

- Thermal engineering

- Industrial durability

- Safety compliance

The key question is not why laser cleaners are expensive—but whether they generate sufficient operational savings and performance advantages for your specific application.

Laser cleaning machines appear expensive when compared superficially to abrasive or chemical cleaning methods. However, from a photonics engineering standpoint, they are highly sophisticated precision systems built around advanced fiber laser technology. Their cost is justified by component quality, system integration, industrial reliability, safety compliance, and long-term economic advantages. For industries prioritizing precision, environmental sustainability, and automation compatibility, laser cleaning is not merely a tool—it is a strategic technological upgrade.

Let’s Talk Honestly About Your Cleaning Needs

At BOGONG Machinery, we do not believe in selling overpriced equipment. We believe in engineering solutions that make economic sense. If you are considering a laser cleaner and want a clear technical evaluation—power selection, ROI estimation, application testing—we are ready to provide real data, not sales talk.

Contact BOGONG Machinery today and let’s determine whether laser cleaning is the right investment for your operation.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com