What are 6 dangers of lasers?

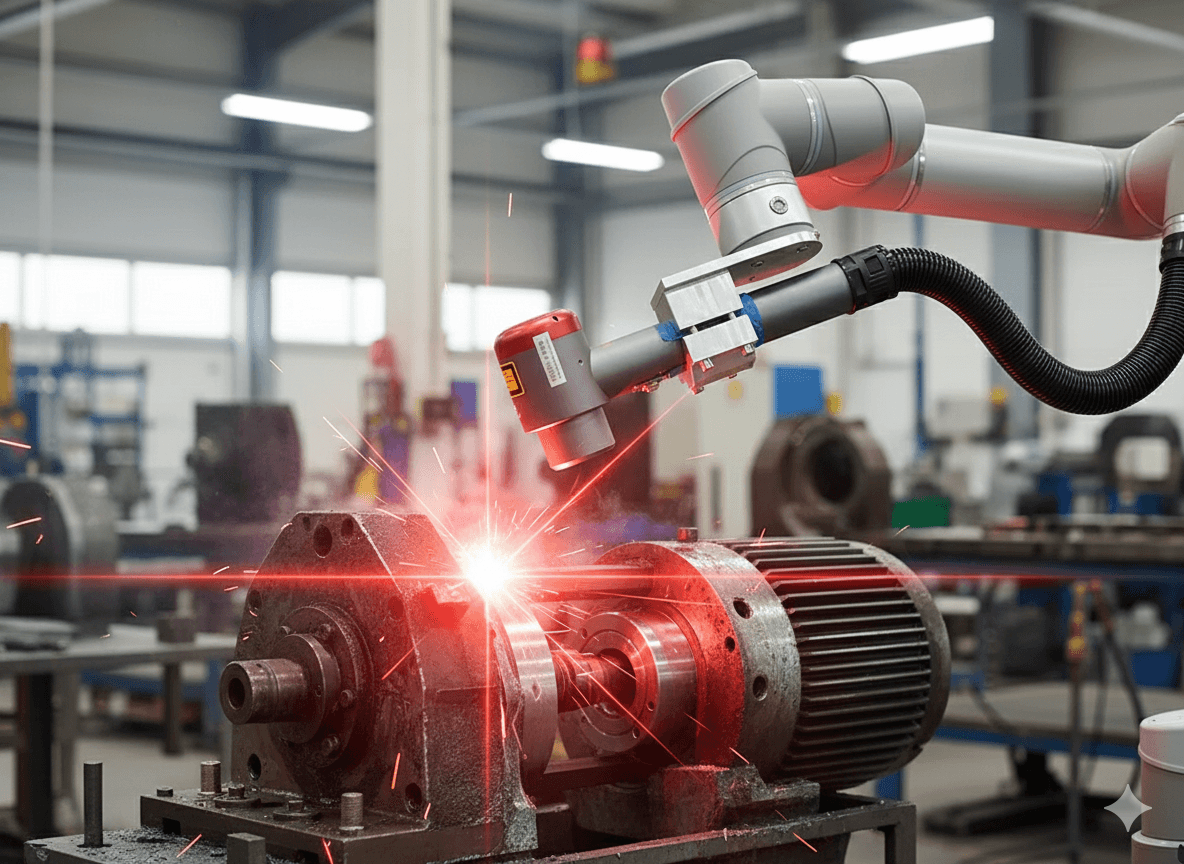

Lasers are powerful, precise, and transformative tools across industries—from manufacturing and medical surgery to communications and scientific research. However, the same properties that make lasers effective—high energy density, coherence, and directional intensity—also make them hazardous when misused or improperly controlled. Many operators underestimate laser risks because there is no visible flame, no mechanical contact, and often no immediate sensation of injury. Unfortunately, laser-related accidents can cause permanent eye damage, skin burns, fires, toxic exposure, and even electrical injury within milliseconds. Understanding laser hazards is not optional—it is a critical component of safe operation, especially for Class 3B and Class 4 industrial laser systems.

The six primary dangers of lasers are: eye injury (retinal damage or blindness), skin burns, fire and explosion risk, toxic fume inhalation, electrical shock, and secondary hazards such as reflected beam exposure or mechanical system failure. These risks increase significantly with higher-power systems, especially Class 4 industrial lasers. Proper engineering controls, protective equipment, training, and regulatory compliance are essential to mitigate these dangers.

Before examining each hazard in depth, it is important to understand that laser risk depends on wavelength, power density, exposure duration, beam divergence, and reflectivity of surrounding materials. A low-power visible laser pointer and a 1000W fiber laser operate under entirely different risk categories. Industrial laser cleaning, cutting, welding, and marking systems demand professional hazard management.

1. Eye Injury (Retinal and Corneal Damage)

Eye injury is the most serious and well-documented laser hazard. The human eye focuses incoming light onto the retina, amplifying laser energy up to 100,000 times compared to the incident beam.

Why Laser Eye Damage Is So Severe

- The retina lacks pain receptors.

- Damage can occur in less than 0.25 seconds.

- Even low-power beams can cause permanent blind spots.

- Infrared lasers are invisible but still focus on the retina.

Injury Mechanisms by Wavelength

| Wavelength Range | Affected Eye Region | Typical Injury Type |

|---|---|---|

| 400–700 nm (Visible) | Retina | Thermal retinal burns |

| 700–1400 nm (Near IR) | Retina | Deep retinal coagulation |

| 1400–3000 nm | Cornea | Corneal burns |

| >3000 nm | Cornea | Surface tissue vaporization |

Industrial fiber lasers (typically 1064 nm) fall in the near-infrared range—highly dangerous because the beam is invisible and bypasses the blink reflex.

Protective eyewear must match the specific laser wavelength and optical density (OD).

2. Skin Burns

Although skin is less sensitive than the eye, high-power lasers can cause:

- Thermal burns

- Blistering

- Tissue carbonization

- Long-term scarring

Short pulse durations may cause micro-explosive ablation, while continuous-wave lasers can produce deep thermal burns.

Skin Damage Risk Factors

| Laser Type | Burn Risk Level |

|---|---|

| Low-Power Class 2 | Minimal |

| Class 3B | Moderate |

| Class 4 Industrial | High |

| Pulsed High Peak Power | Very High |

Skin burns are especially dangerous in laser welding and cutting environments.

3. Fire and Explosion Hazard

High-energy laser beams can ignite combustible materials.

Materials at Risk

- Paper and cardboard

- Plastics

- Dust particles

- Flammable vapors

- Wood surfaces

- Solvent residues

Laser cleaning and laser cutting environments often contain particulate matter and vaporized residues. If proper ventilation is absent, fire risk increases significantly.

Fire Risk Conditions

| Risk Factor | Effect |

|---|---|

| High Beam Power | Increased ignition probability |

| Poor Ventilation | Vapor accumulation |

| Reflective Surfaces | Uncontrolled beam redirection |

| Combustible Dust | Explosion hazard |

Industrial safety protocols must include fire extinguishers rated for electrical and metal fires.

4. Toxic Fume and Particulate Exposure

When lasers ablate materials, they generate:

- Metal oxide fumes

- Paint decomposition gases

- Polymer vapors

- Fine particulate matter (PM2.5 and smaller)

Laser cleaning of rust or paint produces airborne contaminants that may include:

- Lead (from old coatings)

- Chromium compounds

- Organic solvents

- Carbon monoxide

Common Laser-Generated Airborne Hazards

| Process | Emission Type |

|---|---|

| Rust Removal | Iron oxide particulates |

| Paint Stripping | VOCs and toxic gases |

| Plastic Processing | Toxic polymer fumes |

| Composite Cutting | Carbon fiber dust |

Fume extraction systems with HEPA and activated carbon filtration are mandatory in industrial settings.

5. Electrical Shock Hazard

Industrial laser systems require high-voltage power supplies. Risks include:

- Improper grounding

- Damaged cables

- Water leakage in cooling systems

- Maintenance without proper lockout procedures

Fiber laser sources often operate at high internal voltages. Attempting to service a system without disconnecting power can result in serious injury.

Electrical Risk Factors

| Hazard Source | Consequence |

|---|---|

| Wet Environment | Shock risk |

| Exposed Wiring | Electrocution |

| Improper Maintenance | Fatal injury |

| Voltage Fluctuation | System failure |

Qualified technicians should handle electrical servicing.

6. Secondary Hazards (Reflections and Mechanical Risks)

Laser beams reflect off metal surfaces, especially polished aluminum, copper, and stainless steel. Reflected beams can redirect energy unexpectedly.

Types of Laser Reflection

| Reflection Type | Risk Level |

|---|---|

| Specular Reflection | Extremely High |

| Diffuse Reflection | Moderate |

| Scattered Reflection | Lower but still hazardous |

Secondary hazards also include:

- Mechanical motion from gantry systems

- Cooling system failures

- Optical component breakage

- Plasma flash exposure

In laser cleaning operations, reflected beams from rusted metal surfaces are a major concern.

Laser Classification and Associated Danger Levels

Lasers are classified according to international standards (IEC 60825-1).

| Laser Class | Description | Hazard Level |

|---|---|---|

| Class 1 | Safe under normal use | Low |

| Class 2 | Visible, low power | Minimal |

| Class 3R | Reduced risk | Moderate |

| Class 3B | Direct beam hazardous | High |

| Class 4 | Direct & reflected beam hazardous | Very High |

Most industrial laser cleaning, cutting, and welding machines fall under Class 4.

Why Invisible Infrared Lasers Are Particularly Dangerous

Near-infrared wavelengths (700–1400 nm) penetrate deeply into the eye and are invisible. Because there is no blink reflex, exposure duration may be longer, increasing damage severity.

This is why fiber laser systems require strict engineering controls.

Laser Safety Controls Hierarchy

Effective laser safety follows a hierarchy:

- Engineering controls (enclosures, interlocks)

- Administrative controls (training, SOPs)

- Personal protective equipment (PPE)

Safety Control Effectiveness Comparison

| Control Type | Effectiveness |

|---|---|

| Full Enclosure | Very High |

| Interlocked Doors | High |

| Safety Training | Moderate |

| PPE Only | Lowest Alone |

PPE should never be the sole safety measure.

Long-Term Biological Effects

Chronic exposure to low-level laser radiation is less documented but may include:

- Eye strain

- Temporary flash blindness

- Photochemical tissue damage (for UV lasers)

- Cumulative retinal stress

Ultraviolet lasers introduce additional DNA damage risks not present in infrared systems.

Laser Accidents: Common Causes

Statistical reviews show most laser accidents result from:

- Bypassed interlocks

- Misaligned optics

- Inadequate training

- Improper eyewear

- Reflective surfaces

- Lack of ventilation

Human error is the dominant contributing factor.

Preventive Measures Summary

| Danger | Prevention Strategy |

|---|---|

| Eye Injury | OD-rated goggles, enclosures |

| Skin Burns | Protective clothing |

| Fire | Fire-resistant environment |

| Toxic Fumes | Fume extraction systems |

| Electrical Shock | Proper grounding |

| Reflections | Non-reflective surroundings |

Laser systems must be treated as high-energy industrial tools—not consumer devices.

Conclusion

Lasers are among the most precise and efficient technologies in modern industry, but they are also capable of causing severe and irreversible harm if improperly handled. The six primary dangers—eye injury, skin burns, fire risk, toxic fume inhalation, electrical shock, and reflected beam hazards—are all preventable through correct engineering design, disciplined operation, and strict safety compliance. Industrial Class 4 laser systems demand respect, training, and structured safety protocols.

When safety is engineered into the process from the beginning, laser technology becomes one of the safest and most productive tools in manufacturing.

Speak With Our Laser Safety Experts at BOGONG Machinery

If you are operating or planning to install an industrial laser cleaning or processing system, our engineering team at BOGONG Machinery can help you evaluate safety risks, recommend protective measures, and ensure full compliance with international laser safety standards.

We provide:

• Professional safety consultation

• Industrial laser cleaning system design

• Parameter optimization support

• Full technical documentation

• Factory-direct supply and training

BOGONG Machinery

Precision Laser Solutions for Safe and Efficient Industrial Operations

Contact us today to ensure your laser operations are both powerful and protected.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com