Portable Laser Cleaning Machines: A New Era of Mobility

“I took a laser gun into the field, swept it across a corroded bracket — no blasting, no soaking — and when I stood back, the metal beneath looked almost new.” That moment still feels like a turning point. Because what felt like a gimmick turned out to be a tool that redefines how, where, and when we clean.

Portable laser cleaners are rewriting expectations. In the past, you’d bring parts to a cleaning station or dismantle large equipment. Now, mobility brings the power to the part. But beyond convenience, there’s a deeper shift here — in mindset, in workflow, in assumptions of what “cleaning” can be.

In this post, I want to explore not just what these portable machines do, but how their mobility changes the rules, what real challenges lie beneath the surface, and how to think strategically about adding them to your toolset.

Why Mobility Changes Everything (Not Just Where You Clean)

When you make a cleaning tool portable, you don’t just change location — you change the entire decision calculus. Here are some shifts I’ve observed:

- Time turned into action: You don’t wait to batch parts; you clean on demand, on site. That can reduce downtime, avoid shipping costs, or rescue parts before further degradation.

- Accessibility unlocked: Hard-to-reach areas, large assemblies, or in-place structures become candidates—you no longer need disassembly or parts movement.

- Safety & environment shift: You trade fixed enclosures for portable safety zones, you must manage fumes and reflections in varied spaces—your operational envelope changes.

- Mindset of precision over brute force: Smaller, mobile lasers demand more finesse. You can’t blast everything; you must pick your battles, tune your parameters, and be mindful of collateral effects.

- New limits emerge: Power supply, cooling, weight, optics protection—all become constraints you must live with. Mobility demands compromise.

In short: portable lasers don’t just solve old problems more flexibly—they create a new set of problems you must plan for. The winners will be those who understand both sides.

What “Portable” Actually Means: Types & Trade-Offs

Before you pick one, know that “portable” has degrees. The portable class spans from handheld “laser guns” to cart-mounted systems to self-contained suitcases. Each carries trade-offs.

Handheld / Gun-style units

- Truly mobile, maneuverable into tight spots

- Lower power, lighter cooling, more vulnerable optics

- Requires extremely careful parameter control to avoid substrate damage

- Safety is trickier—reflections, stray beams, and operator posture matter more

Cart or Trolley units

- A compromise between mobility and power

- Laser head connected by fiber or cable to cart housing

- Better cooling and power capacity than purely handheld

- Still usable in field, but with more infrastructure (hose, power cord) constraints

Suitcase / Modular portable systems

- Laser modules, optics, exhaust and power packed into flyable cases

- Flexible deployment but moderate power

- Often used for repair, heritage restoration, machinery maintenance function

Each step toward more portability tends to reduce maximum power, increase sensitivity to heat management, and amplify the need for protective handling and maintenance.

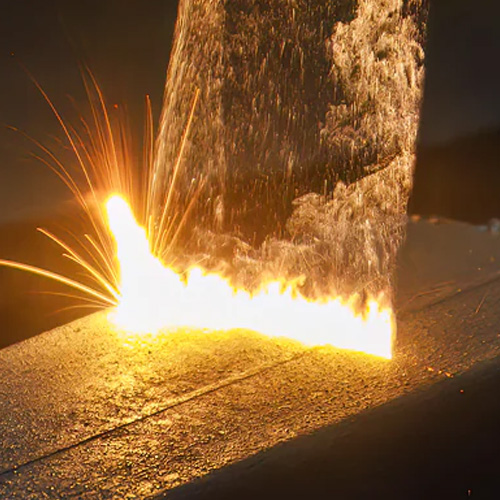

How Portable Laser Cleaning Actually Works — Not Just Theory

To use portable lasers effectively, you must grasp the underlying mechanics intimately. Mobility adds constraints, so the margin for error shrinks. Here’s a deeper view:

The parameter dance under mobility constraints

In a portable context, you must juggle:

- Power density: With lower average power, you often need to concentrate energy via beam focusing or slower scans

- Pulse width & repetition: If pulses overlap or come too fast, you risk cumulative heating

- Spot size & overlap: You may choose smaller spots to get intensity, but that slows coverage

- Cooling lag & thermal hotspots: Portable cooling is weaker, meaning you must avoid dwell or repeated passes

- Drift & alignment sensitivity: Vibrations, operator motion, cable flex all introduce beam drift — portable units demand frequent calibration

In lab settings you might tolerate a bit of drift or error; in the field, every tiny misalignment can cause scorch, haze, or residual residues.

Managing fume, debris & reflections in chaotic environments

When you move out of controlled labs, you confront:

- Variable extraction environments: No perfect enclosures—dust, soot, vapor may leak

- Unseen reflectors: Metal shards, tools, support structures may reflect stray beams

- Ambient conditions: temperature, humidity, dust, vibration—all interfere with optics and beam quality

- Optics contamination: sprayback, micro-particles, soot — portable systems’ optics become highly vulnerable

Therefore, any portable laser setup must include robust fume/vapor extraction, shielding strategies, and optics protection protocols (e.g. purge windows, sacrificial shields, regular cleaning).

Substrate & part risk: smaller margin, higher risk

Because portable units usually operate with tighter energy budgets, and in more variable conditions, the margin between effective cleaning and substrate damage narrows. Mis-tuned parameters, uneven surfaces, or even angle variations can cause:

- Micro-melting

- Surface discoloration or tempering

- Residual haze or redeposition

- Edge burns, pits, or alteration of microstructure

Thus, portable units demand more operator skill, more parameter tuning, and more ongoing monitoring than fixed, overbuilt machines.

Where Portable Lasers Shine — and Where They Falter

Even with their constraints, portable laser cleaners bring unique strengths. And yet, not every job suits them. You must know when to pick them—and when to defer to heavier gear.

Ideal use-cases

- On-site maintenance or repair: cleaning weld prep, removing rust on structural members in situ, restoring machinery without disassembly

- Rare or large assemblies: bridges, tanks, scaffolding, structural steel that can’t be moved

- Touch-up & finishing: removing residual oxides, fine cleanup after blasting or coating

- Emergency remediation: field incidents, corrosion “hot spots,” site inspections

- Cultural heritage & restoration: cleaning sculptures, monuments, building facades in place

In those situations, portability isn’t a luxury — it’s often the only practical option.

Weaknesses & limits you can’t ignore

- Throughput ceiling: you won’t beat fixed high-power systems on bulk removal

- Power/cooling constraints: larger jobs may overtax portable cooling systems

- Durability & drift over time: rough handling, travel, vibrations accelerate misalignment and optics wear

- Operator dependency: more skill needed, more room for human error

- Safety complexities: you bring the laser into varied environments; each brings new reflection, vapor, or containment challenges

If your workload is dominated by thick coatings, large surfaces, or high-volume removal, a hybrid plan may be best—use portable lasers for edges, finishing, or touch-ups, and keep heavier systems for bulk work.

How to Evaluate Portable Laser Systems with Depth

When selecting a portable system, go beyond spec sheets. Ask questions few others ask. Here’s a checklist I suggest:

- Real part trial in your conditions — not coupons in clean labs

- Parameter transparency — get full pulse, scanning, spot, overlap ranges

- Optics and drift tolerance — how forgiving is alignment when the machine flexes or vibrates

- Cooling & duty cycle — how long can it sustainably run before heat affects performance

- Fume extraction & shielding design — how is the system protecting optics and environment in open field settings

- Ease & frequency of calibration / maintenance — how easy is it to clean or realign in the field

- Safety controls & interlocks — portable use demands extra caution

- Modularity & upgrade path — can power modules, optics or beam heads be swapped or scaled

- Operational envelope mapping — define surfaces, angles, distances where the tool can reliably clean

- Support & spare parts — portable tools travel, get bumped, and need spares

If your prospective vendor can’t or won’t let you test your worst-case part, or only shows clean coupon tests, that’s a red flag.

A Narrative Use-Case to Ground the Vision

Let me walk you through a plausible scenario I’ve seen (and advised):

A wind turbine maintenance team must clean corrosion and coatings from base flanges and support brackets 80 ft high on a turbine tower. Traditional methods require hoisting scaffolding, blasting media, or chemically treating—risky, slow, messy.

They bring a cart-mounted portable fiber laser system. The technician positions the “gun” on a boom arm with height reach. The system runs short pulses, adjustable scanning paths, with built-in extraction canopy to catch vapor. In one hour, they clean rust and old coating from a 2 m² surface. They follow up with neutralizing coatings and no rework required.

They repeated this monthly for maintenance stops. The portability meant no disassembly, minimal lifting, and lower crew risk. The system eventually paid back in reduced scaffolding, consumables, and downtime.

In that scenario, the portable laser was not a fancy toy — it became a strategic asset.

Final Thoughts: Mobility Demands Respect, Not Novelty

Portable laser cleaning machines are exciting. They open possibilities that static systems can’t. But they also demand deeper thinking.

You win not by buying the most powerful portable, but by choosing the right one for your parts, risk tolerance, and field conditions—and then operating it with discipline, feedback, safety, and continuous reflection.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com