Handheld vs. Robotic Laser Cleaners: What’s Best for Industrial Use

You’re standing in a machine shop at dawn. Parts waiting, deadlines looming, technicians already wiping grease from hands. On the bench, you see two machines shining behind glass: one, a handheld laser rig; the other, a robotic arm sweeping over a cell. Which is your better bet?

That question is not theoretical — it’s strategic. Your decision says where you lean: toward flexibility or toward scale. Toward human creativity or mechanized consistency. Toward the edge of uncertainty or toward the safety of predictable cycles. In this piece, I want to take you inside that tension — with stories, regrets, and frameworks that help you choose (or combine) intelligently.

Why This Matters More Than Specs

Yes — throughput, cost, repeatability, footprint — those metrics are essential. But I’ve found that the real differentiators aren’t in datasheets. They’re in these places:

- What happens six months in, when one operator is gone, parts have changed, and the cleaning isn’t “standard” anymore

- Where the pain hides — in calibration drift, re-fixturing, training, optics cleaning, fallback modes

- How your team feels about control, risk, and process ownership

A machine that looks perfect on day one can become brittle, frustrating, or expensive if you chose poorly. So let’s dig below the surface.

Handheld: The Human in the Loop

The Emotional & Operational Beauty of Handheld

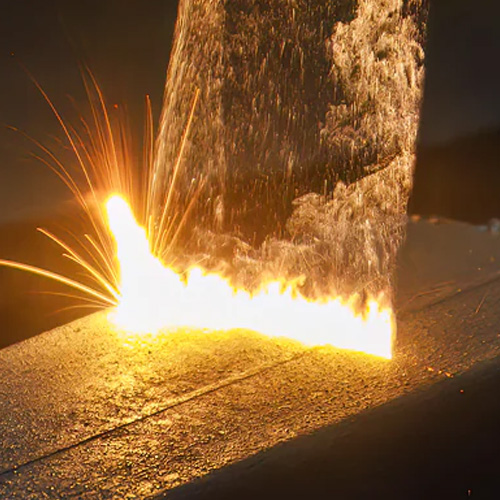

When you hand someone a laser gun, you’re handing them agency. They can tilt, pivot, slow down, hit an odd corner. That freedom is its strength: you don’t need perfect fixturing, line-of-sight everywhere, or perfect CAD-to-part repeatability. In shop settings where variation is the norm, that adaptability is gold.

In fact, in one shop I worked in, we had a weird bracket with undercuts. The robotic cell would miss 10% of surfaces. The handheld operator, seeing the shadow, flipped angle mid-sweep and got the job. That moment earned more confidence in that tool than any spec sheet ever would.

The Hidden Fragility of Handheld

Yet that flexibility comes with fragility:

- Quality drift is real. Two operators may clean the “same part” and get noticeable variation. Fatigue, speed, hand wobble, angle — they all whisper errors.

- Training is underappreciated. A frontline operator needs to know how to read surfaces, slow in tough zones, back off when smear is happening. That kind of intuition takes weeks.

- Optics and beam alignment shift more under human motion. Bumps, cable flex, jostling — they all accumulate.

- Safety is riskier. The beam is exposed; reflections, stray angles, hidden reflections — you must guard, enforce interlocks, train constantly.

You trade “built-in rigidity” for “fragile adaptability.”

Robotic: The Machine in the Loop

What Robotics Deliver

Robots bring you what humans struggle to guarantee:

- Repeatability. If programmed, they hit the same path, speed, focus, overlap every cycle. The day-to-day scatter goes down.

- Throughput scaling. A robot doesn’t get tired, doesn’t slack, doesn’t demand overtime.

- Enclosure & safety advantage. Cages, interlocks, zones: robots are easier to box off and manage risk.

- Integration. You can tie the laser cell into upstream/downstream conveyors, inspections, or sensors.

One automotive shop I visited had a robotic cell cleaning weld lines on thousands of brackets per shift. The consistency and output they got simply beat what five human operators could manage — and with better pass rates.

But Robotics Demand Discipline

Robotic systems bring their own demons:

- Change is expensive. If part geometry shifts, or tolerances drift, a robotic path that worked yesterday might fail today. Reprogramming, re-fixturing, realignment — those are real costs.

- Rigidity can be a liability. If your workflow is dynamic — odd parts, prototypes, one-offs — rigid robots will frustrate you.

- Upfront overhead is high. You’ll spend money on fixtures, safety enclosures, control systems, motion planning. That’s not optional.

- Fault tolerance is low. A robot glitch, a misalignment, an optical drift — and entire cells stop. Downtime can bite hard.

- Calibration and maintenance demand specialization. You’ll need robot engineers, service contracts, spare parts, regular calibration schedules.

Robotics are great — if you build around their strengths and guard against their failure modes.

Deep Decision Levers: What Really Moves the Needle

Let’s talk about the internal levers you should weigh — not just features, but signals that reveal where your success lies.

1. Variation vs. Volume

If your parts seldom change — same geometry, same orientation, stable fixturing — robotics is gold. But if you regularly introduce new parts, pilot runs, or changes — handheld’s flexibility keeps you alive in that world.

2. Margin on Mistakes

Can your process absorb a few mis-cleans, rework, or operator variation? Or do you need near-zero defects? The stricter your downstream quality tolerance (e.g. weld prep, aerospace surface), the more you’ll lean robotic.

3. Hidden Cost of Adaptation

Consider: how much do you spend re-fixturing, retesting, training, cleaning optics, recalibrating under handheld mode? Over time, those “minor overheads” accumulate. Build a model of “year 2 cost differential.”

4. Team psychology & trust

I’ve seen teams resist robotic automation because it felt like removing control. Others resist handheld tools because they fear operator inconsistency. Sometimes the “best” tech fails because your people don’t trust it. Involve your operators early — let them pilot, compare, trust the data.

5. Fallback & hybrid design

Design for fallback. Even a robotic cell should have a mode for manual override. Likewise, handheld tools should have fixture aids so an operator can “borrow” consistency when needed. Blending both isn’t capitulation — it’s strategic hedging.

A Scenario: How I’d Build a Transition Strategy

If I were in your shoes, with mid-volume jobs, odd parts, and ambitions to scale, here’s how I’d approach this:

- Start handheld. Use it for prototypes, maintenance, variable parts. Let it prove value, build confidence, gather data (clean times, operator variation, part coverage).

- Instrument heavily. Log data: which parts always need rework? Where do operators struggle? Where does drift show?

- Identify stable sub-sets. Find components or operations that rarely change and are ideal for robotics.

- Pilot a robotic cell on those stable subsets. Use lessons from handheld “failures” to design paths, fixtures, fallback zones.

- Over time, expand robotic domain while keeping handheld for exceptions. Maintain a unified toolset and cross-trained teams.

That approach gives you safety, reduces risk of “betting big and being wrong,” and lets automation grow around your real process.

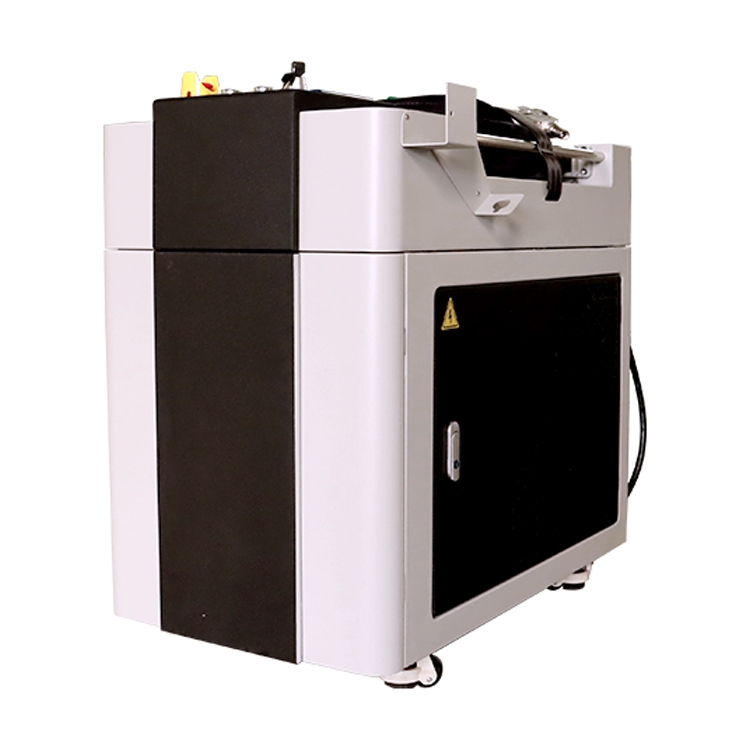

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com