Air-Cooled vs. Water-Cooled Laser Cleaning Machines: Pros and Cons

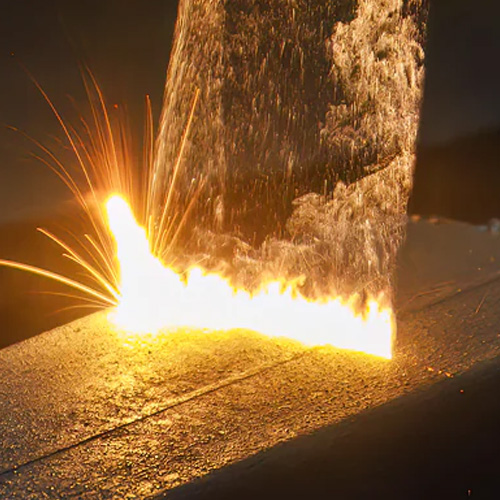

When I first walked into a plant that installed a water-cooled laser cleaning unit, I saw a technician hunched under pipes, juggling coolant tests, ice packs, and alarms. A week later, I visited another shop that used an air-cooled laser — they’d lost half a shift because the system overheated midday. Cooling is not a backroom detail. It’s a battleground for uptime, reliability, and trust.

If you pick the “wrong” cooling method, your laser system may underperform, throttle, or become a maintenance headache you regret for years. So let’s go deeper — not just listing pros and cons, but exploring how those tradeoffs play out in real operations, what assumptions fail, and how to think like a laser systems architect.

Why Cooling Is More Than Heat Removal

Before we compare air vs water, it helps to understand what cooling really does in a laser system, and why it’s mission-critical:

- A laser is never 100% efficient. A lot of input energy becomes waste heat. That heat must be removed continuously, or else optics drift, power drops, damage happens.

- Cooling stability affects beam quality, optical alignment, thermal lensing, and system lifetime. Overheating one diode or mirror can cascade into misalignment or permanent damage.

- Under real shop conditions — ambient heat, dust, vibration, fluctuating loads — cooling is the safety margin. The system must survive not just “ideal mode” but worst-case day-after-hot shift mode.

With that in mind, here’s how I see the tension between air and water cooling — not just which is “better,” but which risks you carry.

Air-Cooled Laser Cleaning Machines — The Lean, Agile Option

When Air Cooling Feels Right

I tend to favor air-cooled designs when:

- Your laser power or duty cycle is moderate (not pushing the thermal envelope)

- You need portability, field use, or mobility

- Infrastructure (water lines, plumbing, chillers) is hard or expensive

- You want lower maintenance overhead

- You want fewer points of failure — no leaks, pumps, coolant chemistry

That’s what many vendors highlight. For example, air-cooled systems are more compact and portable since they don’t need external chillers or pumps.

But the Hidden Risks & Realities

Here’s where things get tricky — tradeoffs that aren’t obvious until you live with the system:

- Ceiling on Thermal Budget Air cooling simply can’t remove heat as effectively as water when you push the duty cycle or power. If your use case edges upward, you risk thermal throttling or forced derating mid-shift.

- Sensitivity to Ambient Conditions If your shop is 95 °F or runs in summer, or if your cooling vents get dusty or blocked, your cooling margin shrinks. Suddenly what seemed safe becomes unstable.

- Airflow & Noise To push heat, you may need bigger, faster fans. That increases noise, vibration, and even shop air disruptions. Also, turbulent airflow can pick up dust and blow it over optics or beams.

- Hidden Hot Spots & Thermal Gradients In large laser modules, some internal components are farther from airflow. Those may run hotter, drift, or age faster — you may get asymmetric stress or alignment shift.

- Throttling & Duty Limits Many “air-cooled” units advertise a duty cycle (e.g. 60 % at full power). Push it further, and the system may reduce power, shut down, or degrade performance.

- Fan & Filter Maintenance In dusty environments, fans and filters clog. If airflow is compromised, cooling collapses. Operators need to monitor, clean, replace. It becomes a new maintenance chore.

So air cooling is graceful — until it fails. You must design with margins.

Water-Cooled Laser Cleaning Machines — The Heavy-Duty Workhorse

When Water Cooling Becomes the Better Option

I lean toward water cooling in these conditions:

- Your power and duty cycle need pushing into “continuous high load” territory

- You want thermal stability, minimal drift, consistent performance over long runs

- Your environment is harsh, hot, or dusty — water cooling gives more buffer

- You have infrastructure (rooms, plumbing, pumps) already or can feasibly build it

- You want headroom for future scaling

Water cooling gives you a bigger “thermal envelope” — you work farther from limits, which means smoother performance and fewer surprises.

The Real Overheads & Pitfalls

Water cooling is not free. Here’s where many projects stumble:

- Complexity and Points of Failure Pump failures, hose leaks, valve issues, pump priming—every extra component is a failure mode.

- Coolant Quality & Maintenance You must manage deionized water or treated coolant. If you get scaling, corrosion, microbial growth, your cooling paths clog, performance drops. Many systems require monthly or periodic water changes. From laser welding sources: water must be changed monthly to prevent algae clogging. ([Laser Welder][2])

- Leaks & Damage Risk Water leaks in an electronics/optics environment are dangerous. One poorly sealed connector can ruin expensive components. Any leak detection system or containment adds cost.

- Size, Weight, and Infrastructure The chiller, reservoir, pumps and plumbing add footprint. For portable or tight environments, that’s nontrivial. Also, power requirements go up.

- Startup & Warm-Up Behavior Chillers need time. You may have to wait for the coolant to reach stable temperature before full operation. That introduces operational delays.

- Freezing or Seasonal Risks In cold environments, coolant can freeze or require antifreeze mixes, which complicate design or risk damage when startup conditions vary.

- Long-Term Degradation Pumps wear, hoses age, seals degrade — over years, maintenance can eat you if not planned.

In short: water cooling gives you robustness and margin—but with more engineering overhead. Pick it only when you need more than air can deliver.

A Side-by-Side Mindset Matrix

Here’s a lens I use when advising clients: as requirements or conditions tighten, where does each system buckle?

| Factor | Air Cooling Risks | Water Cooling Risks | | | | | | Ambient heat / summer peaks | Cooling margin erodes, performance drop | Chiller must reject more heat, more electrical load | | Dust / dirty shops | Fan/filter clog, airflow loss | Heat exchanger or radiator clog, pump strain | | Long continuous runs | Overheating, forced derate | Chiller pump stress, coolant circulation fatigue | | Scaling future power | You hit a ceiling you can’t cross | You may waste your cooling margin if underutilized | | Portability / field service | Feasible, lighter | Harder, heavy, plumbing challenges | | Maintenance culture | Easier but proactive filter care needed | Requires pump, coolant, hose maintenance discipline |

If you find yourself often in the left column (warm shop, dusty, long shifts), water cooling gives you a safety net. But if you’re mostly in the right column (short tasks, mobility, clean environment), air cooling is leaner.

A Live Example: Two Shops, Two Choices

I once worked with Shop A, doing moderate-volume rust cleanup on mold tooling. They initially chose an air-cooled laser. Most days, it was fine — but on hot afternoons, the unit throttled, losing cleaning speed and requiring extra cycles. Eventually they upgraded parts of their operation to a water-cooled variant to handle the worst-case conditions.

Meanwhile, Shop B needed a portable system for field repair of architectural metalwork. They chose air-cooled precisely because portability and ease-of-deployment mattered more than continuous full-power operation. They scheduled lighter duty or part-swaps to avoid overheating.

Each made a choice aligned with their trade-offs. Neither was wrong — but each paid the consequences in different ways.

How to Decide (With a Stronger Mindset)

Okay — here’s a decision path I’d present to leadership if I were you:

- Define your “worst-case continuous run” scenario Don’t design for average; design for maximum continuous load under heat, shift, dust conditions.

- Test prototypes under stress Get both cooling variants (or simulate), run long cycles at peak ambient, check drift, power, thermal behavior.

- Plan coupon & optical drift margins See how much temperature drift you can tolerate in your beam path, optics, and your process before quality breaks.

- Add safety margins (20–30 %) Don’t plan to run right at cooling limit — leave headroom for that day when fans get dusty, or you push harder.

- Maintenance & workforce alignment Choose the variant your team can reliably maintain. If no one wants to babysit coolant systems, lean air; if your staff includes facility engineers, water is viable.

- Future-proof for scaling If you might upgrade to higher power, having water cooling gives you headroom. But if scaling is unlikely, an overbuilt water-cooling system may be wasted.

- Design for fallback A water-cooled system should gracefully derate if pump fails rather than catastrophically break. An air-cooled system should flag issues early, not just collapse mid-run.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com