What Can a 300W Laser Cleaner Do

We’ll go beyond the marketing hype to examine real capability, strengths, limitations, and what to expect when you use a 300 W laser cleaner across those use cases you care about: mold cleaning, rust, paint, welding prep, precision parts, electronics, relics, etc.

A Quick Baseline: What “300 W” Implies

“300 W” is your headline spec. But that number doesn’t tell the whole story. In practical use, the effectiveness of a 300 W laser cleaner depends on:

- Pulse energy (per pulse) and pulse duration

- Beam quality & focus (spot size, uniformity)

- Scanning speed, overlap, and path design

- Cooling capability and thermal stability

- Substrate and contaminant absorption (how well contaminant absorbs the laser vs substrate)

- Optical path losses, mirror quality, dust, drift

A well-designed 300 W system, with good optics and control, can deliver surprisingly capable cleaning — but with limits. Many vendors advertise 300 W cleaners for industrial rust removal, mold cleaning, paint removal, etc. For example, Some company markets a 300 W portable laser rust removal machine to “clean rust, oxide, paint, and coating from metal or any hard surface” with precision.

Let’s walk through your list of use cases and see where 300 W can shine, where it may struggle, and what constraints you must design against.

Use Cases & Practical Realities

1. Mold Cleaning

What 300 W can do:

- Remove residual mold release agents, oily films, light carbonization, thin oxide layers or stuck residues.

- Clean fine features (grooves, edges) if you use a small, well-focused spot and slow passes.

Challenges / constraints:

- For deeply embedded buildup or thick, sticky polymer residues, the energy may be insufficient on first pass. You’ll need multiple slow passes, which increases heat risk if cooling is inadequate.

- Mold surface detail or protrusions may cast shadows; beam angle and scanning path must adapt.

- Over-cleaning or overexposure might slightly change surface texture (if the thermal margin is tight).

With care, a 300 W unit can replace chemical or mechanical cleaning for many mold maintenance tasks — especially where you want non-contact precision.

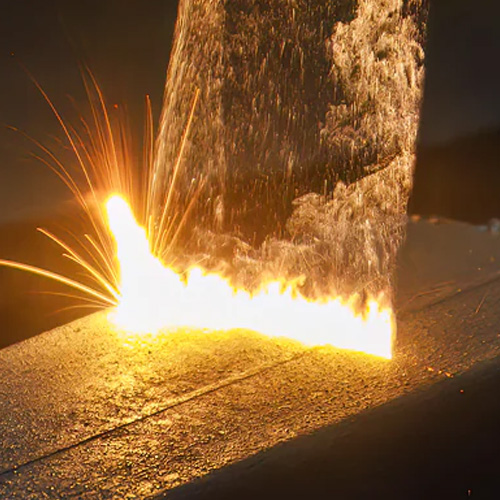

2. Industrial Rust Removal

What 300 W can do:

- Remove surface rust, scale, oxidation layers, and light corrosion on metal parts.

- Clean weld seams, bolts, flanges, tools, tank exteriors, etc.

- For moderate rust thicknesses, you can sweep across with moderate overlap and get good results in a pass or two.

Challenges / constraints:

- Thick rust or deeply pitted corrosion may require repeated passes, possibly with reduced scanning speed, which increases thermal stress.

- For large surfaces, speed becomes limiting — a 300 W cleaner won’t compete with high-power systems for bulk removal.

- In dusty or corrosive ambient conditions, optics may fog, decreasing efficiency over time unless cleaned.

Many vendors place 300 W units in their rust removal lineups.

3. Old Paint / Film Removal

What 300 W can do:

- Strip paint or thin film coatings (lacquer, varnish, primers) from metal surfaces, especially when the coating is fairly uniform and not too thick.

- Localized paint removal (patches, touchups) where you can linger carefully.

Challenges / constraints:

- Multi-layered paint, thick coatings, or enamel finishes will demand more energy or slower scanning.

- It may struggle on coatings that reflect or absorb weakly at your laser wavelength.

- There’s a risk of thermal load on the substrate if the scanning is too slow or repeated.

In blog form, one vendor’s content lists paint, film, and contaminants as target removals for 100 W lasers.

4. Welding Pre-Treatment & Post-Weld (Cleaning / Prep)

What 300 W can do:

- Clean base metal before welding (removing oxide, scale, grime) to improve weld quality.

- Remove weld spatter, surface oxidation, discoloration after welding (de-slag, clean finish).

- In localized zones, you can re-clean the heat-affected zone edges without full abrasive blasting.

Challenges / constraints:

- Post-weld scale or thick oxide may demand slower passes or multiple cycles.

- The heat from welding plus the laser’s heat must be managed — cooling and timing scrutiny is more critical.

- Precision in stop zones matters — you don’t want to erode edges or change dimensions.

A 300 W laser can serve as a precision tool for weld surface prep and cleanup, especially in smaller parts or repair tasks.

5. Deesterification / Cleaning Precision Parts

(“Deesterification” here could mean removing residue, coatings, esters, organic layers, etc.)

What 300 W can do:

- Remove thin organic films, residue, grease, oxidation, passivation layers from small precision parts (fasteners, small machined components).

- Because precision parts often demand minimal heat stress, a controlled, well-tuned 300 W system can do this without damaging tolerances.

Challenges / constraints:

- If the residue is thick or chemically robust, achieving clean removal without substrate damage is delicate.

- Fixtures, fixturing, beam alignment, and drift tolerance become critical.

- Ambient contamination (dust, vapor) may degrade performance quickly on small parts.

A 300 W laser is attractive for precision cleaning, but success depends heavily on optics, control, and drift management.

6. Decontamination / Oxide Layer Removal in Electronics

What 300 W can do:

- Clean small metallic leads, connector contacts, oxide layers, surface contamination on PCBs or devices (if configured for micro-scale scanning).

- Remove flux remnants, solder oxides, or surface oxide films on metal contacts, provided the substrate tolerance for heat is considered.

Challenges / constraints:

- Very small features require excellent beam control and minimal drift — even micro-misalignment can damage tiny traces.

- Sensitive substrate layers (plastic, Si, coatings) may suffer damage if stray heat diffuses.

- Fumes or vapor from removed contaminants must be evacuated to avoid redeposition or damage.

In general, 300 W is on the border line: capable for moderate electronic deoxidation tasks, but you risk collateral damage if not handled expertly.

7. Cleaning Cultural Relics / Historical Artifacts

What 300 W can do:

- Remove corrosion, rust, oxide crust, surface encrustation, old coatings, grime or dirt from metal, stone, bronze, or artifacts — carefully, layer by layer.

- Gentle settings (low overlap, slow pass, careful parameter tuning) can preserve surface detail while cleaning.

Challenges / constraints:

- Many relics have very low margins for damage — micro patina, texture, surface detail. You must operate with high finesse.

- Variability in material (composite surfaces, embedded dirt) means you’ll need careful trial runs.

- Operator skill, optics cleanliness, drift control, environmental control become critical.

Many laser cleaning projects in cultural heritage use pulsed lasers, and the literature often refers to laser ablation as a method for cleaning surfaces without damaging substrate. ([Wikipedia][4]) A 100 W unit can participate in that field, though with more constraint than higher-power models.

Synthesis: When 300W Is Enough — and When It Isn’t

From the above, here’s a summary map:

| Use Cases Where 300 W Can Be Solid | Use Cases Where 300 W May Struggle or Require Support |

|---|---|

| Mold cleaning (residue, release agent removal) | Deep rust, thick paint removal, large-area bulk jobs |

| Light industrial rust / scale removal | Very thick corrosion or surface spalling |

| Localized paint or film removal | Multi-layer coating removal over large areas |

| Welding prep or finish cleanup in small spots | Heavy weld scale or broad post-weld oxidation |

| Precision parts decontamination (thin films) | Thick residue, robust chemical coatings, delicate substrates |

| Small electronic oxide / contamination cleaning | Large-area or complex printed circuit cleaning |

| Cultural relic surface cleanup (light encrustations) | Encrustations that require bulk removal or mixed substrate risk |

Key enablers if 300 W is to succeed:

- Beam control: focus, scanning, overlap, pulse tuning — the more control, the better your results.

- High-quality optics & low-loss beam path: every mirror, window, dust particle matters.

- Strong cooling & thermal margin: avoid drift, overheating, lens focus shifts.

- Pre-testing and safe trial passes: always begin on a small area to tune parameters.

- Good fume extraction, debris handling, operator discipline.

- Modularity: ability to upgrade or augment (higher power head, better optics) if you hit limits.

Opinion & Competitive Edge: Why a Thoughtful 300W Machine Can Outperform a Cheaper 100W

- The 100 W unit may have better thermal balancing, smarter pulse control, better optics, and more stable beam — which means fewer defects, less rework, more consistency

- It forces discipline: operators with a lower “power budget” are more cautious, cleaner, more attentive — they’re less likely to overexpose or cause collateral damage

- For many real tasks, you don’t need brute force — you need finesse. A 300 W unit used right can meet specifications with less collateral stress

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com