Collaborative Robot Laser Cleaning Machines in Industrial Applications

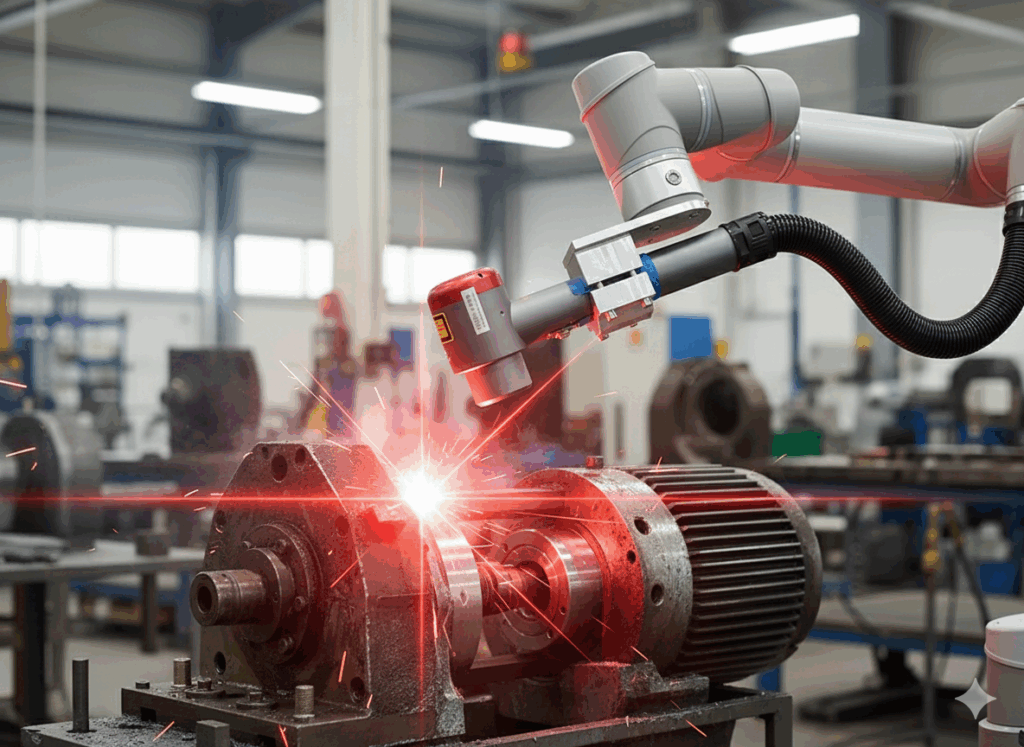

Every time I walk a shop floor, I see that ideal: workers with handheld lasers, wiping surfaces, trying to hit tight corners. But I also see bottlenecks—fatigue, inconsistent coverage, rework. That’s why cobot (collaborative robot) laser cleaners are stirring interest. They promise consistency, repeatability, safety—and to free your team from the drudgery of repetitive cleaning.

In this article, I’ll walk you through not just what cobot-based laser cleaning machines can do, but how to envision them, where they succeed (and when they don’t), and what you must design for if you want them to survive years in your plant.

The Promise: Why Combine Cobots + Laser Cleaners?

Let’s begin by articulating the vision—and the real benefits you might realize (or not).

- Consistency over human variability: A robot doesn’t tire, doesn’t drift in speed, doesn’t forget a region. It repeats the same path with the same speed, so your cleaning quality becomes predictable. For cleaning tasks, that’s gold. TechBriefs describes laser-wielding cobots in workcells that “excel at tasks like laser cleaning of parts which involve repetition, freeing up employees to work on other activities.” ([Tech Briefs][1])

- Safer operations: Rather than operators approaching sharp, dirty, or hot surfaces, cobots can handle much of the reach, staying inside guarded areas, minimizing exposure.

- Better integration & automation: A cobot + laser head can plug into your automation infrastructure—move with conveyors, integrate with upstream inspection, schedule cleaning windows, coordinate motion. The CleanTech IR-6040 robotic cell is an example: it encloses the robot + laser in a cell for safe, repeatable operation. ([laserphotonics.com][2])

- Flexible re-deployment: Whereas a fixed or custom automated cell might be rigid, cobots tend to be more modular and reprogrammable. LightWELD, for instance, pairs cobots with laser welding/cleaning presets, enabling a shop to flex between tasks. ([IPG Photonics Corporation][3])

- Lower consumables & waste: Laser cleaning avoids abrasive media, chemicals, or blast grit, reducing environmental burden. ([IPG Photonics Corporation][4])

But to realize these promises, you must navigate the tensions. Let’s examine what designing and operating a cobot laser cleaning system really demands.

Anatomy: What a Cobot Laser Cleaning System Looks Like

Before diving into design, let’s identify the parts and how they should interact.

- Cobot arm / manipulator Acts as the motion skeleton. Must have sufficient reach, payload (to carry laser head + cables), and repeatability for your cleaning tolerances.

- Laser cleaning head (pulsed or beam source) The device that emits the laser for cleaning. It has optics, scanner or beam shaping, protective windows, cooling, and I/O interfaces.

- Beam delivery / optical path Fiber, mirrors, scanning optics, lenses. This path must maintain beam quality, avoid loss, and survive contamination.

- Cable / cooling management You need flexible, durable routing of optical fiber, power cables, coolant lines (if required), and air or gas purge if used.

- Control & digital I/O interface The robot controller must interface with the laser (start/stop, power knobs, fault signals) and perhaps monitor status, safety interlocks, etc.

- Safety & enclosure / guarding Laser protections (shields, interlocks), fume extraction, containment zones, and human safety systems.

- Work fixturing & parts interface Fixtures, part alignment systems, jigs, and often sensors or vision to position the part or surface.

- Software & path planning / parameter tuning A layer to teach the robot path (manually, drag-teach, or offline), assign laser parameters per segment, handle transitions, optimize speed, dwell time, etc.

When these components are well designed to work together, the cobot laser cleaner becomes a coherent system—not just a robot plus a laser.

How to Use a Cobot Laser Cleaner (Process Flow & Best Practices)

Here’s how a smart shop might bring the system to life, step by step, with attention to real-world pitfalls.

Step 1: Initial Setup & Calibration

- Mount the laser head on the cobot wrist or flange. Balance weight, ensure stiffness and minimal flex.

- Route fiber, coolant, cables with slack loops that won’t constrain motion — avoid binding or drag.

- Define the coordinate systems (robot base, laser head focus frame) and calibrate them—so path planning “knows” distance from surface.

- Optionally use vision or a 3D scanner to detect surface geometry deviations or workpiece placement offsets.

Step 2: Path Planning & Parameter Assignment

- Using the teach pendant or offline programming, define paths or trajectories where the laser sweeps.

- Break down the surface or part into segments (flat zones, curves, edges). Each may call for different laser parameters (power, frequency, scan speed, overlap).

- Establish transitions or lead-in/lead-out arcs to avoid sudden power changes or beam jumps.

- Simulate in software, if possible, to check for collisions, overreach, or undercoverage.

Step 3: Test & Tune on a Coupon

- Before running full parts, test on a sacrificial coupon or small region of actual parts.

- Observe removal efficacy, substrate strain, surface finish, and thermal behavior. Adjust parameters (power, pulse width, scan speed) iteratively.

- Monitor beam stability, drift (optics shift), and thermal buildup.

Step 4: Integration & Execution (Start/Stop Control)

- Use digital I/O signals (DO) from the robot controller to trigger the laser on/off at precise moments.

- You may introduce small delays or ramping between states to avoid over or under exposure.

- The robot controller should monitor laser status, faults, beam interlocks.

- In production, plan part loading/unloading, part indexing, and cycle timing in harmony with robot moves and laser dwell.

Step 5: Monitoring, Feedback & Maintenance

- Log parameters, removal performance, cleaning time, drift, alarms.

- Set thresholds: if the beam output drops, or cleaning force weakens, flag maintenance.

- Periodically inspect optics windows, mirrors, beam alignment. Clean/replace as needed.

- Monitor coolant, purge gas, ventilation, and thermal state.

Step 6: Evolution & Reprogramming

- As your part mix or geometry evolves, be ready to reprogram or refine paths.

- A flexible system enables reuse for new parts, rather than rigid “one-time” programming.

- You may layer on vision / adaptive feedback to adjust paths in real time for surface deviations.

What Cobot Laser Cleaners Do Well—Use Cases & Strengths

Let’s match the system to real industrial jobs. Where cobot laser cleaning often shines — and where you must watch out.

Cleaning Complex & Irregular Surfaces

Cobot systems can sweep curved parts, stepped surfaces, arcs, and irregular geometries that are hard to fixture or access. Where handcrafted path planning meets complexity, robots bring order.

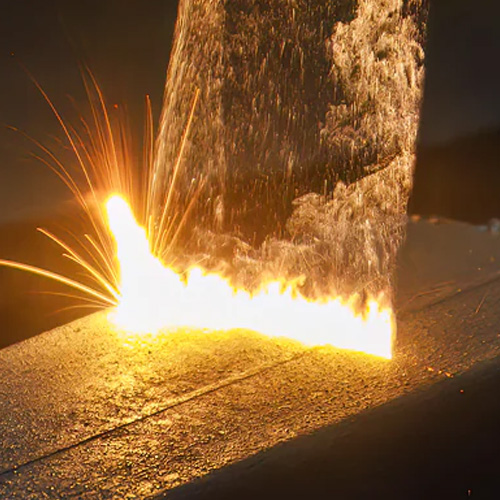

Rust / Oxide Removal on Metal Parts

Cobots are effective at cleaning rust or oxidation layers before painting, coating, or in refurbishment. Their repeatability ensures consistent removal depth and surface readiness.

Paint / Coating Stripping / Rework

For repaint jobs, remanufacturing, or spot repair, cobots can iteratively strip coatings without grinding, reducing substrate damage, particularly in automotive, aerospace or machine parts.

Pre-Welding & Post-Welding Surface Prep

Cobots excel in preparing weld surfaces (scale/oxide removal) or cleaning residual spatter or oxidation after welding, especially in repeated joint geometries.

Precision Parts & Fine Cleaning

Cobot + laser can handle small precision parts—like mold cavities, tool steel parts, or fine mechanical assemblies—with fine control, provided the robot and beam stability are high.

Cultural & Heritage Object Cleaning

For delicate restoration tasks (bronze, sculptures, architectural metal surfaces), cobot laser cleaning can offer controlled, precise cleaning that a human handheld could risk by variable hand pressure.

Mold Maintenance & Tooling

In mold shops, cleaning residual release agent, carbon residues, or small deposits inside cavities is tedious manually. A cobot laser cleaner can reach deep tooling regions consistently and reduce manual labor.

The Hard Truths & Trade-Offs You Must Guard Against

It’s not magic. Even the best cobot laser systems carry real risks. Understanding these helps you design defensively.

- Calibration & Drift: Cobots are mechanical systems and drift will occur. Optics, alignment, robot flex, mounting creep must be monitored and periodically recalibrated.

- Motion Constraints & Payload: The weight and cable drag of the laser head plus fiber/coolant lines can stress the robot. If path planning doesn’t account for inertia, jerk, or cable drag, you’ll see path error or collisions.

- Beam Loss & Contamination: Dust, soot, vapor deposition degrade mirrors and windows. A contaminated beam path reduces effective power. Vigilance is key.

- Safety & Laser Risks: Even “collaborative” arms must be properly shielded when wielding laser beams. Interlocks, protective enclosures, beam stops, and risk assessments are essential.

- Cycle Time & Synchronization: Robot moves, cleaning dwell times, part indexing, safety gating must all coordinate. A mismatch or slack in one link kills throughput.

- Complexity & Cost: The cost of motion system, safety, optics, programming, calibration, integration is nontrivial. Overdesign or underbudgeting is common.

- Fallback Modes: What if a beam fails or robot path can’t reach a pocket? You’ll want fallback (manual, alternative cleaning) built in.

One industry article describes how laser cleaning robotic workcells can “turbocharge” manufacturing but emphasizes that they must be enclosed, safe, and engineered precisely to perform reliably. ([Tech Briefs][1])

Strategic Questions to Ask Before You Commit (for Depth)

Here are deep questions you should demand answers to—questions many procurement teams skip:

- What is the repeatability and pose drift tolerance of the cobot system over time and temperature?

- How is the beam path protected or cleaned when contamination accumulates?

- What is the actual usable laser power at the surface, after optics and path losses?

- How does the system handle shadowed regions or occluded surfaces—are multiple passes or auxiliary paths planned?

- What fail-safe modes exist if the robot, laser, or cooling subsystem fails mid-operation?

- Who owns the calibration regime and how is uptime prioritized?

- How modular is the integration—can you swap laser heads, upgrade power, reprogram new parts?

- How safe is the system—has it been risk assessed per ISO 10218 / ISO/TS 15066 for collaborative robotics with laser use?

- What is the long-term maintenance cost of optics, cooling, mirrors, alignment repair?

- What metrics will you log (cleaning time vs expected, beam output drift, rework rate), and how will you feed them back to improve the program?

Conclusion: When Cobots + Lasers Become Real Industrial Assets

A cobot laser cleaning machine is not just a fancy gadget—it has the potential to become a sustainable, high-value asset in your production system. But only if you build it with respect for calibration, optics, safety, path planning, and feedback loops.

When done well, you’ll gain:

- repeatable, consistent cleaning

- reduced manual labor and fatigue

- safer operations

- flexible reprogramming for new parts

- lower long-term waste (no consumables, fewer abrasives)

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com