Your Ultimate Guide to Importing a Laser Cleaning Machine from China: 5 Things You Must Know

I still remember one client who thought importing a “cheap Chinese laser cleaner” was straightforward. Then the container sat in customs for a week, missing safety certifications, mis-classified tariff codes, and a missing import license. That “discount” became a painful lesson in hidden cost and risk.

If you’re considering importing a laser cleaning machine from China, the savings can be tempting — but the pitfalls are real. In this guide, I’ll walk you through five critical areas you must understand (and manage) so your import doesn’t turn into a mess or a money trap. Think of this as the “truth serum” version of import advice.

1. Regulatory & Safety Compliance Is Non-Negotioable

Laser Safety & Export Controls

Lasers aren’t just “electronics” — many countries regulate them because of their radiation risk. In the U.S., lasers above certain power levels must comply with CDRH / FDA rules (21 CFR Part 1040, etc.) to operate legally. ([photonlexicon.com][1])

If you import a laser system that lacks required safety design, labeling or documentation, it may be denied entry or require costly retrofits or modifications. Always insist your Chinese supplier provide full test reports, safety certifications, interlock documentation, and compliance with local laser/radiation codes.

Import Licenses & Permits

Depending on where you are, “machinery with radiation or electrical regulation” may require special permits. Some jurisdictions demand import licenses for high-powered laser systems.

Best practice: before you place an order, verify with your country’s customs or trade authority whether a license, registration, or special approval is needed for “laser cleaning machines.” Don’t assume “just another piece of hardware.”

Certification & Labeling

Be clear in your contract: your supplier must deliver machines with appropriate nameplates, safety labels, CE (or your region’s equivalent), and documentation. If local standards demand UL, CSA, FCC, or other suite of marks, ensure your machine meets them (or can be upgraded locally).

Also, check the HS code classification used in China and your import country. For example, “laser cleaning system” might fall under HS 845611 (other measuring / testing apparatus) in China’s export classification. ([hs.e-to-china.com][3])

If misclassified, customs may reassign your import to a higher duty bracket, delay clearance, or reject it. Accurate HS classification and matching certificates are essential.

2. Total Landed Cost & Risk Premiums

Many buyers focus on the “FOB price” (factory price) and forget all the extra costs lurking behind the scenes. A smart importer builds a full landed cost model including:

- Freight & Insurance (FOB vs CIF vs DAP) Decide who bears the risk and cost of shipping, insurance, and freight. If supplier gives “FOB,” you arrange export transport and insurance. If “CIF” or “DAP,” they include more logistics. Misunderstand where your responsibility starts. Some Chinese laser suppliers already expect to quote CIF or DAP to your port.

- Customs Duties, Tariffs, Taxes & VAT Import duty rates on machinery vary by country. In some cases, “industrial machinery” may get favorable rates; in others, there are “special tariffs” on imported machines. You must also budget for local value-added tax, import processing fees, customs broker fees, inspections, and potential anti-dumping duties.

- Clearance Delays & Holding Costs If customs scrutiny, missing documents, or noncompliance causes delays, your container may be held for days or weeks — incurring demurrage, port storage, and extra costs. Build buffer days (5–10 days or more) in your plan.

- Installation, Local Modifications & Testing Once the machine arrives, you may need to adapt wiring, safety systems, local voltage, cooling, or modify enclosures. Also, testing and commissioning may require local service or expert support.

- Spare Parts, Optics, Maintenance, Warranty Shipping Importing optics, mirrors, cooling parts, and having the ability to replace them fast is key. If a supplier won’t commit to spare parts stock or fast shipping, your maintenance window might suffer.

- Currency Risk & Payment Terms Many Chinese suppliers expect partial deposit and balance after inspection. Currency fluctuations, wire transfer fees, or escrow arrangements can add risk. If you commit too much upfront, you’re exposed.

When you compare two suppliers, it’s not just their machine price — it’s everything above. The real cheapest option might end up being the one with better compliance, warranty, and logistics support.

3. Vetting the Supplier: Red Flags & Trust Markers

The supplier you choose can make or break your import. Many “cheap machines” collapse under hidden defects. Here’s what I personally scrutinize.

Factory Visit, References & Samples

If possible, visit the factory (or send a trusted partner) to see production quality: cable routing, optics cleanliness, alignment rigs, test benches. Ask for video of machines in operation (in actual settings, not staged). Request reference clients (in your region, if possible) and talk to them.

Export Experience & International Certifications

A supplier used to exporting to your market is more likely to understand your country’s compliance, documentation, packaging, and shipping norms. Look for prior exporters, CE certificates, export licenses, and a track record of international customers.

Documentation & Transparency

Insist on:

- Detailed machine specifications (power, beam, optics path losses, cooling specs)

- Safety diagrams and compliance reports

- Bill of materials and parts list

- Inspection reports, factory acceptance test (FAT) video

- Warranty terms, spare parts price list, support channels

If the supplier resists providing documentation or gives vague answers like “you only need the machine, we’ll worry about paperwork later,” that’s a red flag.

After-sales Support & Local Presence

A machine is not useful if downtime kills you. Make sure your supplier commits to:

- Local or regional support (or a service network)

- Spare parts availability and shipping options

- Remote diagnostics, calibration instructions, alignment support

- Responsiveness in case of claims or defects

Sometimes paying slightly more for better support and parts availability is worth far more than “cheap upfront.”

4. Logistics, Packaging & Transport Design

Even before the machine leaves China, good importers design for survivability.

Rugged Packaging & Shock Protection

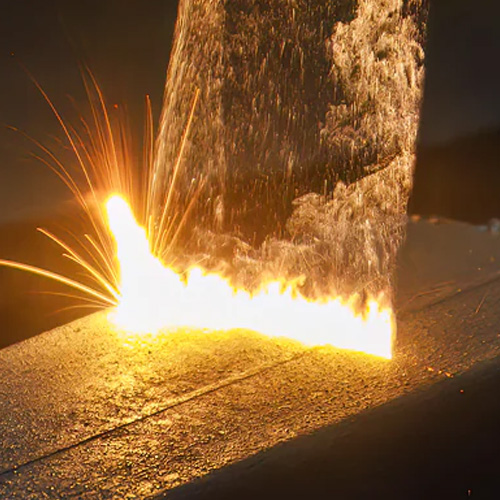

Laser cleaning machines contain optics, mirrors, sensitive alignments — they are fragile. Insist on durable crates with foam, shock absorbing mounts, vibration dampeners, and protection for optics windows. Use “fragile / laser equipment” warnings, humidity desiccants, and sealed crates.

Export & Customs in China

To export, the Chinese side must comply with their export regulations: proper export declarations, customs inspections, certificates of origin, export licenses if needed, and packaging approvals. Many suppliers overlook the export side, leading to delays.

China’s customs documentation typically include commercial invoice, packing list, bill of lading, certificate of origin, and maybe CE safety certificate.

Make sure the supplier coordinates with a reliable freight forwarder who understands machinery exports.

Transport Mode & Route Planning

Decide sea freight vs air freight vs multimodal. High-value, urgent machines might be flown (but cost is steep). For large machines, sea freight (FCL container) is typical—allow for port handling, inland transport, crane rigging, heavy lift. Plan for the last leg: can your site accept the container, remove packaging, place the machine?

Insurance & Risk Coverage

Insure the cargo door-to-door, with coverage for damage, theft, delays, customs seizure. Use coverage that includes “machinery in transit” and check for limitations around laser / high-value items.

5. Commissioning, Installation & Validation at Home

Importing is only half the battle — making the machine work reliably is where many fail.

Factory Acceptance Test (FAT) & Pre-Shipment Validation

Before shipping, insist on FAT: run the machine with your sample parts, test all functions (power, beam quality, scanning, cooling, safety interlocks). Record video and parameter logs. If possible, witness (in person or via video). Accept or reject based on performance margins, not just “it runs.”

Local Installation & Training

Once the machine arrives, ensure expert installation, alignment, optics tuning, cooling setup, and operator training. In many cases, the supplier may send a technician (at additional cost) for commissioning. Confirm this before procurement.

Quality Validation & Performance Benchmarking

Run tests on known parts or coupons. Confirm cleaning speed, consistency, beam drift, output stability over time, thermal behaviour, calibration drift. Compare to FAT benchmarks.

Maintenance Protocol & Preventive Plan

Set up daily, weekly, monthly, and periodic maintenance checks: optics cleaning, alignment checks, cooling fluid checks, filters, drift monitoring. Log all deviations and channel learnings back to your supplier for improvements.

Feedback Loop & Software Updates

Machines may need updates in firmware, safety patches, or calibration tweaks. Secure a channel for updates or patches. Ask for remote diagnostic and calibration capabilities via software or remote support.

Epilogue: Importing with Wisdom, Not Just Price Spec

Importing a laser cleaning machine from China can offer immense value — if you do it with eyes open. But many buying mistakes stem from underestimating regulatory, support, logistics, or hidden cost friction.

Here are my closing tips:

- Price is only the beginning: The real cost lies in compliance, downtime, parts, support, and making the machine work reliably.

- Plan for failure: Have fallback or service options, spare optics, alignment expertise ready — because in the first 12–24 months, surprises happen.

- Buy a trusted partner, not just a machine: The vendor’s responsiveness, export experience, and support network will matter far more than extra wattage.

- Document everything, test early, validate often: The safest profit you’ll get comes from having clear acceptance criteria and verifying performance, not from assuming “it works.”

- Increment in complexity: If this is your first import, start with a simpler model before scaling to complex, large systems. Learn through doing.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com