What can you clean with a laser cleaning machine?

If you are considering laser cleaning for industrial, maintenance, or manufacturing use, the first and most important question is not how powerful the machine is, but what materials and contaminants it can actually remove in real production conditions. Traditional methods—sandblasting, chemical stripping, grinding—are familiar but come with downsides: surface damage, consumables, waste disposal, and inconsistent results. Laser cleaning promises a cleaner, more controllable alternative, but only if it is applied to the right targets. Misunderstanding its scope leads to disappointment; understanding it unlocks significant technical and commercial value.

A laser cleaning machine can remove rust, oxide layers, paint and coatings, oils and grease, carbon residues, rubber and polymer deposits, surface contaminants, and certain corrosion products from metals and selected non-metal substrates—precisely, selectively, and with minimal base-material damage—when the laser type and parameters are correctly matched to the application.

In this guide, we will systematically break down what laser cleaning can clean, categorized by contaminant type, substrate material, and industrial application. This is written from a manufacturing and engineering perspective, not marketing—so you can decide realistically where laser cleaning fits into your process.

1. Rust and Corrosion Products — The Most Common Laser Cleaning Application

Rust removal is the application most people associate with laser cleaning—and for good reason. Iron oxides absorb laser energy efficiently, while clean steel reflects much of it. This natural contrast creates a wide and forgiving process window.

Laser cleaning can remove:

- Light surface rust (flash rust)

- Medium to heavy corrosion layers

- Oxide scale from hot-rolled steel

- Localized corrosion spots

- Rust around fasteners, edges, and welds

Unlike sandblasting, laser cleaning:

- Does not thin the base metal significantly

- Does not embed abrasive particles

- Can be localized to specific areas

- Produces minimal secondary waste

This makes laser rust removal especially valuable in:

- Equipment maintenance

- Structural steel refurbishment

- Shipbuilding and offshore platforms

- Power plants and pipelines

- Automotive restoration and remanufacturing

It is important to note that extremely thick, flaky corrosion may require multiple passes or a high-power continuous-wave (CW) laser. Laser cleaning is highly effective, but it is still a surface process—not bulk material removal.

2. Paint, Coatings, and Surface Layers

Laser cleaning is widely used for paint and coating removal, particularly when precision matters. It can remove:

- Industrial paints

- Epoxy and polyurethane coatings

- Powder coatings

- Anti-corrosion layers

- Primer layers (selectively)

- Markings and surface films

One of laser cleaning’s key advantages is layer selectivity. With proper parameter control, it is possible to:

- Remove paint while leaving primer intact

- Strip coatings from specific zones only

- Clean edges and complex geometries without masking

Common industries using laser paint removal include:

- Aerospace maintenance

- Automotive manufacturing

- Shipbuilding

- Heavy equipment refurbishment

- Mold and die preparation

However, not all coatings behave the same. Thick elastomeric or rubberized coatings can char and require slower processing. Laser cleaning works best when coatings are well-characterized and trials are performed.

3. Oxides and Weld-Related Contamination

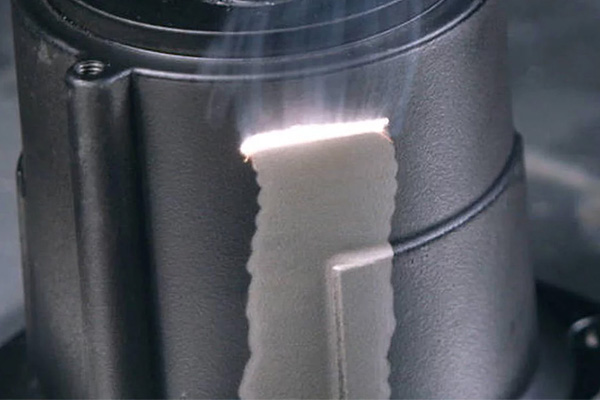

Oxide removal is one of the highest-value laser cleaning applications, especially in welding and joining processes.

Laser cleaning can remove:

- Aluminum oxide layers

- Stainless steel heat tint

- Oxide films before welding or brazing

- Post-weld discoloration

- Surface contamination affecting weld quality

In welding applications, laser cleaning is used:

- Before welding (weld seam preparation)

- After welding (post-weld cleanup)

- In automated welding lines

- In battery and EV manufacturing

Removing oxides and oils before welding:

- Reduces porosity

- Improves weld consistency

- Enhances joint strength

- Reduces spatter and defects

This is an area where pulsed laser cleaning systems are especially effective due to their fine control and minimal heat input.

4. Oils, Grease, and Organic Contaminants

Laser cleaning is highly effective for degreaasing and removal of organic residues, including:

- Oils and lubricants

- Cutting fluids

- Grease films

- Release agents

- Residues from machining

Unlike solvent cleaning, laser degreasing:

- Leaves no chemical residue

- Can be integrated inline

- Reduces chemical handling and disposal

- Can be verified with water-break or surface tests

This application is common in:

- Automotive manufacturing

- Precision machining

- Coating and painting lines

- Electronics and battery production

Laser cleaning does not “wash away” oils; it breaks molecular bonds and vaporizes or dislodges residues. Proper fume extraction is essential for this application.

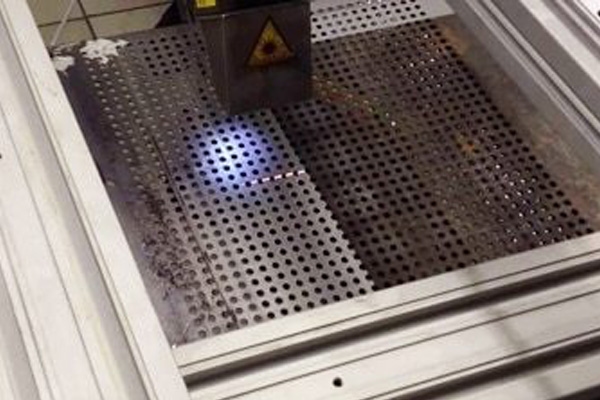

5. Carbon, Soot, and Combustion Residues

Carbon-based contamination absorbs laser energy very efficiently, making it one of the easiest targets for laser cleaning.

Laser cleaning can remove:

- Carbon buildup

- Soot and smoke residue

- Burnt polymer residues

- Engine and exhaust deposits

- Heat-treatment residue

This is why laser cleaning is widely adopted for:

- Mold cleaning (rubber, plastic injection)

- Tire molds

- Foundry tooling

- Heat-treatment fixtures

- Industrial ovens and burners

In mold cleaning specifically, laser cleaning allows molds to be cleaned in place, reducing downtime and avoiding abrasive damage that shortens tool life.

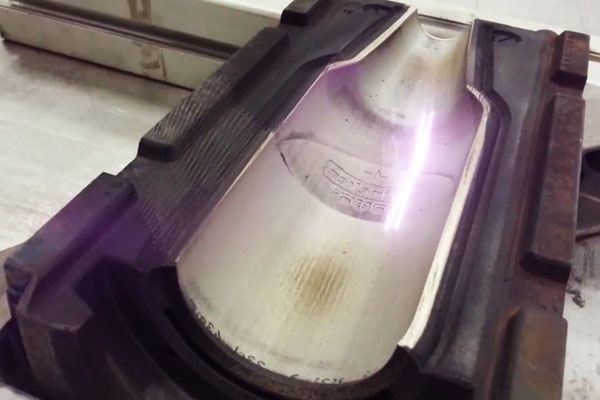

6. Rubber, Polymer, and Release-Agent Residues

Laser cleaning is particularly effective at removing thin layers of rubber or polymer residue, such as:

- Rubber buildup in molds

- Plastic residue

- Adhesive films

- Release agents

- Sealant residues (thin layers)

This is common in:

- Tire manufacturing

- Rubber molding

- Plastic injection molding

- Composite manufacturing

Laser cleaning removes residues without altering mold geometry, preserving surface finish and extending tool life. This is a major economic driver in mold-intensive industries.

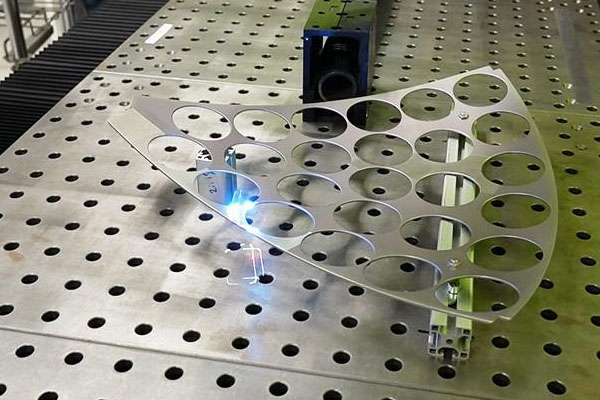

7. Surface Preparation for Coating and Bonding

Laser cleaning is increasingly used as a surface preparation step, not just for cleaning but for performance enhancement.

It can:

- Remove contaminants prior to painting

- Prepare surfaces for adhesive bonding

- Improve coating adhesion consistency

- Replace or supplement mechanical abrasion

While laser cleaning does not always create the same roughness profile as blasting, it produces:

- Clean, activated surfaces

- Consistent surface energy

- Minimal embedded contamination

This makes it valuable in high-quality coating systems where cleanliness is more critical than aggressive roughness.

8. What Materials Can Be Laser Cleaned?

Laser cleaning works best on metals, including:

- Carbon steel

- Stainless steel

- Aluminum and aluminum alloys

- Copper (with care)

- Titanium

- Nickel alloys

It can also be applied—more selectively—to:

- Stone and masonry (heritage restoration)

- Certain composites

- Glass surface contamination (specialized)

- Some plastics (very carefully, low power)

Highly reflective or heat-sensitive materials require tighter process control and are not always ideal candidates.

9. What Laser Cleaning Is NOT Best At

To be clear and honest, laser cleaning is not ideal for:

- Bulk material removal

- Very thick elastomeric coatings

- Deep internal cavities without line-of-sight

- Low-value, high-volume commodity cleaning where blasting is already optimized

- Applications where surface roughening is the primary goal

Understanding these limits is key to successful use.

10. Summary Table — What Can You Clean with a Laser Cleaning Machine?

| Contaminant Type | Can Laser Clean? | Typical Industries |

|---|---|---|

| Rust & corrosion | Yes | Maintenance, steel, marine |

| Paint & coatings | Yes | Aerospace, automotive |

| Oxides | Yes | Welding, EV, fabrication |

| Oils & grease | Yes | Machining, coating lines |

| Carbon & soot | Yes | Molds, foundry |

| Rubber residue | Yes | Tire, rubber molding |

| Adhesive films | Yes | Composites, assembly |

| Thick bulk material | No | — |

Final Perspective: What Laser Cleaning Is Really Good At

Laser cleaning is best understood as a precision surface removal and preparation technology. It excels when:

- Cleanliness matters more than brute force

- Surface integrity must be preserved

- Waste and consumables must be minimized

- Processes need to be repeatable and automatable

It is not a universal replacement for all cleaning methods—but where it fits, it often outperforms traditional techniques both technically and economically.

Want to Know If Laser Cleaning Fits Your Application?

Choosing a laser cleaning machine based only on power or price is the fastest way to misuse the technology. The real value comes from matching contaminant, material, and process goals. At BOGONG Machinery, we help customers evaluate exactly what they need to clean, test real samples, and select laser cleaning systems that work reliably in production—not just in demonstrations. If you want to know whether laser cleaning is right for your materials or business, contact BOGONG Machinery and start with a practical, application-driven discussion.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com