Laser Cleaning Machine: How It Works

Laser cleaning machines work by using precisely controlled laser energy to remove unwanted surface layers—such as rust, paint, oxides, oil, or residues—without physical contact and with minimal impact on the underlying material. While the operation may look simple from the outside, the mechanism is based on well-understood physics and careful process control rather than brute force. Understanding how laser cleaning actually works is essential for selecting the right machine, setting correct parameters, and achieving reliable industrial results.

In simple terms, a laser cleaning machine delivers concentrated light energy to a surface, where contaminants absorb that energy more readily than the base material. The absorbed energy causes the contaminant layer to break its bond, vaporize, or fragment, allowing it to be removed cleanly while the substrate remains largely unaffected.

Below is a clear, engineering-level explanation of how this happens in practice.

The Core Principle: Selective Energy Absorption

The foundation of laser cleaning is selective absorption. Different materials absorb laser energy at different rates depending on their optical and thermal properties. Rust, oxides, paint, oils, and carbon residues typically absorb laser energy much more efficiently than clean metals such as steel or aluminum.

When the laser beam strikes the surface:

- The contaminant layer absorbs the laser energy rapidly.

- The base material reflects or dissipates much of the energy.

- This difference creates a controllable removal window.

As energy builds in the contaminant layer, its temperature rises extremely quickly—often in microseconds—causing the layer to fracture, vaporize, or detach from the surface.

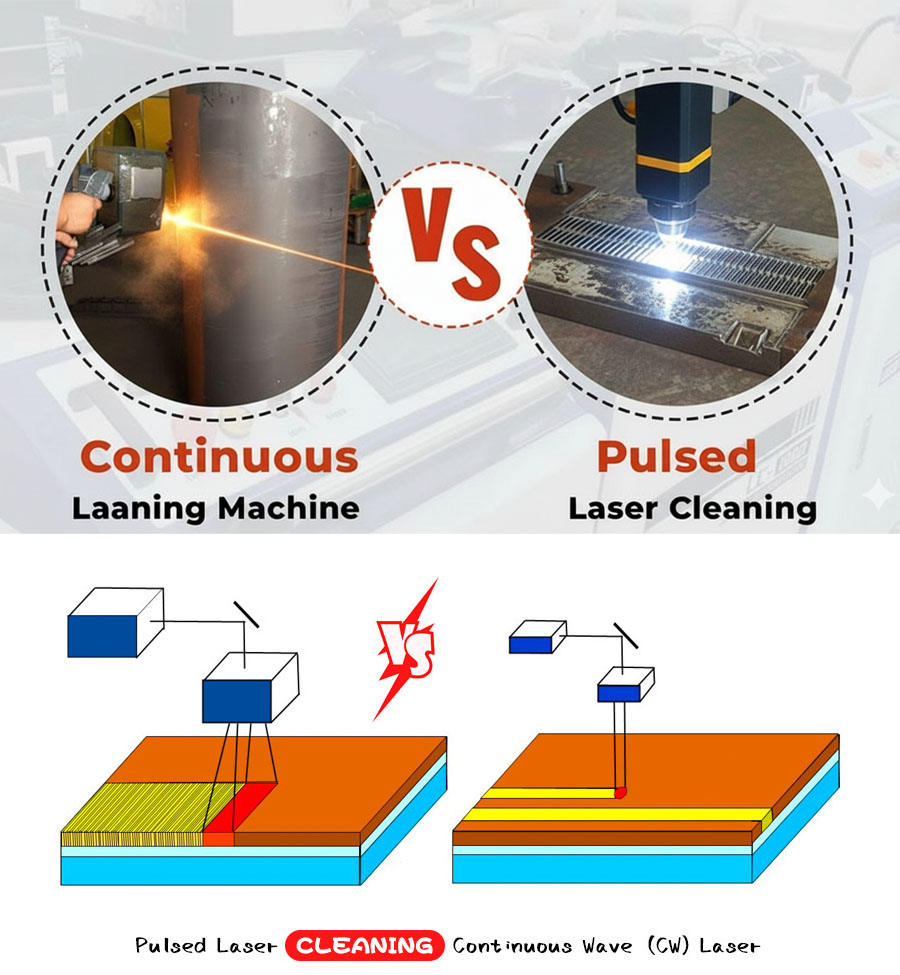

Pulse VS Continuous Laser Cleaning Machine[/caption]

Pulse VS Continuous Laser Cleaning Machine[/caption]

Ablation, Thermal Shock, and Bond Disruption

Laser cleaning does not rely on a single mechanism. Instead, several effects act together depending on laser type and settings.

Laser ablation occurs when the energy density exceeds the removal threshold of the surface layer, causing it to transition into vapor or fine particulate. This is common in paint, oxide, and carbon removal.

Thermal shock plays a major role in rust and oxide removal. Rapid heating causes the contaminant layer to expand faster than the underlying metal, breaking the bond between them.

Bond disruption occurs when organic contaminants such as oils or release agents are heated and decomposed at the molecular level, eliminating adhesion to the substrate.

The goal is always the same: remove the surface layer while staying below the damage threshold of the base material.

Continuous-Wave vs Pulsed Laser Cleaning

Laser cleaning machines typically use either continuous-wave (CW) fiber lasers or pulsed fiber lasers. The working principle is the same, but energy delivery differs.

Continuous-wave laser cleaning delivers a steady stream of energy while a scanning head moves the beam rapidly across the surface. This approach favors high throughput and is commonly used for heavy rust, scale, and large-area coating removal.

Pulsed laser cleaning delivers energy in extremely short bursts with very high peak power but low average heat input. This creates precise, localized effects and is ideal for delicate surfaces, mold cleaning, weld preparation, and thin materials.

In both cases, scanning optics control how the beam moves, ensuring uniform coverage without overheating any single point.

The Role of Scanning and Beam Control

Laser cleaning machines do not hold the beam stationary. Instead, a galvanometer scanning head rapidly moves the laser spot across the surface in controlled patterns.

Key parameters include:

- Scan speed

- Line spacing

- Spot size

- Overlap between passes

These parameters determine how much energy each area receives. Proper scanning ensures:

- Uniform cleaning

- No striping or missed areas

- Minimal heat accumulation

- Repeatable results

From a process perspective, laser cleaning behaves much like CNC machining for surfaces: the beam path and settings matter as much as the power level.

Material Removal Without Physical Contact

One of the defining features of laser cleaning is that it is non-contact. There is no abrasive impact, no mechanical force, and no tool wear in the traditional sense.

This means:

- No surface deformation from impact

- No embedded media

- No tool pressure variability

- Minimal wear on the cleaning head

As a result, laser cleaning is particularly well suited for precision components, molds, thin parts, and surfaces where dimensional integrity matters.

What Happens to the Removed Material?

When contaminants are removed, they are converted into:

- Fine particulate matter

- Vaporized compounds

- Small fragments

These byproducts are immediately captured by a fume extraction system positioned near the cleaning zone. Effective extraction is part of how laser cleaning works in real production—not an optional accessory.

Without extraction, removed material can redeposit or create safety issues. With proper extraction, the process remains clean, controlled, and repeatable.

Why the Base Material Is Not Damaged

A common question is why the base material is not harmed if a high-energy laser is involved. The answer lies in process control.

Laser cleaning parameters are selected so that:

- Energy density exceeds the contaminant removal threshold

- Energy density remains below the substrate damage threshold

- Interaction time is extremely short

- Heat dissipates quickly into the bulk material

When these conditions are met, the base material experiences little to no structural change. This is why parameter development and testing are critical parts of successful laser cleaning implementation.

How Laser Cleaning Is Controlled in Practice

Modern laser cleaning machines include:

- Adjustable power settings

- Preset cleaning recipes

- Real-time monitoring

- Safety interlocks

- Scan pattern control

Operators do not “guess” during cleaning. Once parameters are validated for a given application, they can be reused consistently, enabling industrial-scale repeatability.

Why Laser Cleaning Is Considered a Process, Not a Tool

From an engineering standpoint, laser cleaning is best understood as a controlled surface-processing method, not a handheld gadget. Its effectiveness comes from the interaction of optics, materials science, thermal dynamics, and automation.

When treated as a process—with defined parameters, quality checks, and safety controls—laser cleaning delivers reliable, predictable results across a wide range of applications.

Summary: How a Laser Cleaning Machine Works

Laser cleaning works by directing controlled laser energy onto a surface so that unwanted layers absorb the energy and are removed through ablation, thermal shock, and bond disruption. The underlying material remains intact because energy delivery is precisely managed. Scanning optics, parameter control, and fume extraction together make laser cleaning a clean, repeatable, and industrially viable surface treatment technology.

Want to See How Laser Cleaning Works on Your Material?

Understanding the principle is only the first step. Real results depend on matching laser type, power, and parameters to your specific contaminants and substrates. At BOGONG Machinery, we help customers test real samples, explain the physics in practical terms, and configure laser cleaning systems that work reliably in daily production. If you want to see exactly how laser cleaning will perform on your parts—not just in theory—contact BOGONG Machinery for an application-focused discussion.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com