Best Practices for Operating and Maintaining a Laser Cleaning Machine

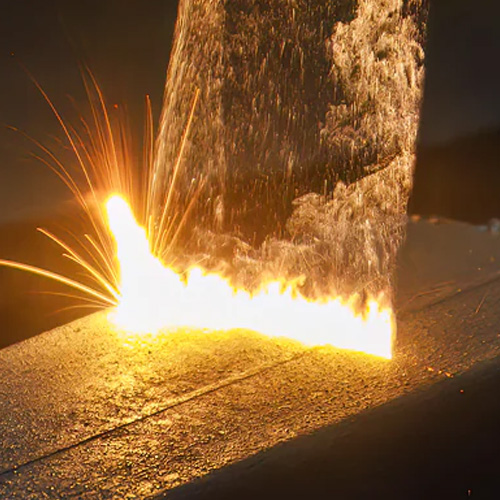

I once visited a plant where operators complained of inconsistent cleaning results. The optics looked “fine” to the untrained eye, but behind a thin film of soot the beam had lost 20 % of its power. Weeks of downtime followed before the root cause surfaced. That taught me: the difference between a reliable laser and one that frustrates your team isn’t just specs — it’s the habits, vigilance, and design of maintenance protocols.

If you want your laser cleaning machine not just to run, but to run well for years, you need practices rooted in respect for optics, thermal systems, and human fallibility. Below is a deeper playbook — not a shallow checklist, but a way to think about operating and maintaining these precision systems.

1. Build a Maintenance Mindset (Culture First)

Before you even flip the on switch, cultivate a culture where care matters.

- Ownership, not just usage. Operators should see the machine as something they care for, not just use. When they notice haze or drift, that becomes a signal, not a nuisance.

- Routine over emergency. The most expensive downtime is unexpected downtime. Schedule preventive tasks rather than waiting for failure.

- Accountability + logs. Record every maintenance action, weird observation, misalignment, or change in performance. Over months, patterns emerge.

- Training & refresh. Even advanced operators benefit from periodic refresh training. The world changes — dust cycles, ambient conditions, contamination loads shift.

A laser system is only as good as the team maintaining it daily.

2. Daily (or Pre-Shift) Rituals: Stay Ahead of Drift

Every day, before you begin cleaning, run quick checks. These small acts are the difference between clean runs and creeping degradation.

- Visual inspection of mirrors, lenses & windows. Look for smudges, condensation, dust, residue. Clean only when necessary. Use lint-free optical swabs + approved solvents. (Many laser-maintenance guides emphasize optics care as critical to preserving beam fidelity.) ([The Fabricator][1])

- Check optical path alignment (if your system has diagnostics). Even slight mechanical shifts can misalign mirrors. Catch drift early.

- Verify cooling & temperature stability. Are coolant levels normal? Is the chiller or cooling loop free of alarms or abnormal readings?

- Inspect airflow and filters. If fans, air vents or filters are clogged, your cooling margin shrinks without warning.

- Check mounts, fasteners & hardware. Loose screws or vibration over time can subtly shift optics or mirror supports.

- Run a small “check pass” on a test coupon. Compare performance (cleaning speed, residue) to baseline. Any deviation is a flag, not to be ignored.

These daily tasks may take just minutes — but they act as your guardrail against creeping failure.

3. Weekly & Bi-Weekly Deep Checks: Reinforce Stability

Beyond daily rituals, deeper checks help catch what daily glance misses.

- Clean optics more thoroughly. Use proper solvent, swabs, from last mirror down to focus lens. Always proceed from upstream to downstream (so you don’t contaminate already cleaned parts). ([IVYCNC][2])

- Check for coatings or film buildup. Sometimes vaporized residues or micro-particles deposit slowly over time—especially in difficult geometries.

- Inspect cooling system components. Check pump operation, inspect hoses for cracks or looseness, validate coolant flow, look for early signs of scale or contamination.

- Lubricate mechanical axes and guide rails. If your laser head or beam delivery system moves (gantry, rails, linear slides), make sure those axes move freely with correct lubricant. ([AP Lazer][3])

- Verify optical mounts & support structures. A small drift under load might only show under longer passes; confirm rigid mounting, no sag, no creep.

The weekly is your “calibration buffer” — reinforce alignment, review data, and prepare for deeper cycles.

4. Monthly / Quarterly Maintenance: Reset & Renew

At this cadence, you should unearth issues before they become emergencies.

- Replace protective windows or sacrificial optics (if your system uses them) before scratch or haze degrade beam quality.

- Flush or replace coolant (for water-cooled systems). The coolant may slowly accumulate ionic contaminants, scale or biofilm. Regular renewal protects your cooling loop. ([AP Lazer][3])

- Inspect the heat-exchange surfaces or radiator fins (if used). Dust or debris on heatsinks reduces thermal transfer.

- Realign or re-optimize the optical path. Do a full alignment check under load and re-center beam path if drift is detected.

- Check system-level tolerances under full load. Run extended cleaning passes, monitor beam output over time, look for slow decay or drift.

- Replace worn mechanical parts. Belts, couplings, mounts, fasteners — even if not visibly faulted — can fatigue.

- Inspect power and control electronics. Dust, heat stress, connector looseness — these gradually degrade over months.

These deeper interventions restore system “health” from baseline wear.

5. Performance Monitoring & Feedback Loops

A laser cleaning machine doesn’t operate in a vacuum (figurative and literal). You must monitor, log, compare, and respond.

- Log beam output, cleaning throughput, dwell times, operator notes. Over time, you can detect gradual drops, shifts, or anomalies.

- Trend anomalies. If on a particular week your cleaning speed for the same coupon drops 5 %, that’s a flag before product parts break spec.

- Cross-reference environmental data. Track ambient temperature, humidity, dust levels — correlate these with shifts in output.

- Use calibration coupons or reference targets. Periodically run a known test part and compare performance over time.

- Root-cause investigations. If something degrades, ask: optics? cooling? alignment? drift? operator technique? Don’t patch symptom — find root.

That feedback loop is what turns maintenance from reactive to predictive.

6. Pitfalls & “Gotchas” (What Many Overlook)

Even well-intentioned teams stumble over these hidden traps:

- Overcleaning optics. Cleaning more often than needed risks scratching coatings or misalignment. Better to inspect and clean only when warranted.

- Using wrong solvents or wipes. Some cleaning agents or abrasive tissues can damage coating surfaces on mirrors or lenses.

- Ignoring small drops in performance. A 2 % drop today may become 20 % in a month. Small dents are early warning.

- Neglecting cooling backup. If your cooling pump slows or partially fails, the system may struggle under heavy loads. Thermal margin collapse is insidious.

- Loose mechanical support. Vibration, thermal expansion, or fatigue can loosen mirror mounts or beam supports over time.

- Not planning for machine drift. Every optical system slowly creeps; designs should allow periodic realignment, not expect eternal “zero drift.”

- Underestimating environment. High dust, smoke, contamination, extreme temps — your “clean lab spec” machine may suffer in real shop environments.

The machine you design for “ideal conditions” must still survive “dirty, hot, unpredictable conditions.”

7. Example Maintenance Plan (Humanized)

Here’s a sample schedule — a living framework you can adapt to your system and workload. It’s not perfect, but it gives structure:

| Cadence | Activity |

|---|---|

| Daily | Visual optics check, cooling status, airflow & filter check, test pass |

| Weekly | Full optics cleaning, inspect mounts, lubricate axes, validate cooling |

| Monthly | Realign optics, replace sacrificial windows, flush/renew coolant, inspect mechanical parts |

| Quarterly | Full load test, deep mechanical check, optics recalibration, review logs |

| Annually | Replace optics, mirror coatings, major mechanical overhaul, vendor calibration |

Don’t rigidly follow—you’ll have to adapt based on usage, environment, and system design. But having something structured helps avoid blind spots.

Final Thoughts: Respect, Consistency, Awareness

If there’s one truth I’ve seen repeated across dozens of facilities: precision systems fail not through dramatic breakdowns, but through neglect of small things. A wisp of dust, a subtle drift, a slow coolant decline — these are the seeds of breakdown.

To run a laser cleaning machine well over years, you need:

- Respect for optics and thermal systems

- Consistency in maintenance, not heroic salvage

- Awareness of environmental change and system drift

- A feedback mindset—not waiting for errors, but watching trends

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com