Can laser cleaning remove paint?

Paint removal is one of the most common, costly, and risk-prone surface treatment tasks in modern industry. From automotive refinishing and aerospace maintenance to ship repair, mold refurbishment, and industrial repainting, paint must often be removed cleanly without damaging the underlying substrate. Traditional methods—chemical stripping, abrasive blasting, and mechanical grinding—have been used for decades, yet each introduces trade-offs in surface damage, labor intensity, waste generation, and environmental compliance. Against this backdrop, laser cleaning has emerged as a compelling alternative, raising a critical and practical question: can laser cleaning actually remove paint effectively, and under what conditions does it make sense?

Yes, laser cleaning can remove paint effectively, selectively, and repeatably, especially on metal substrates. However, its performance depends on paint type, layer thickness, substrate material, laser parameters, and process design. Laser paint removal is not a one-size-fits-all solution, but when correctly applied, it offers unique advantages that traditional methods cannot match.

Why Paint Removal Is Technically Challenging

Paint is engineered to adhere strongly to surfaces and resist environmental stress. This makes it protective—but also difficult to remove. Any paint removal method must overcome three competing requirements:

- Remove coating completely or selectively

- Avoid damaging the substrate

- Maintain efficiency and cost control

Traditional approaches often solve one requirement at the expense of another. Laser cleaning changes this balance by introducing energy-controlled, non-contact removal, but it does not eliminate trade-offs entirely.

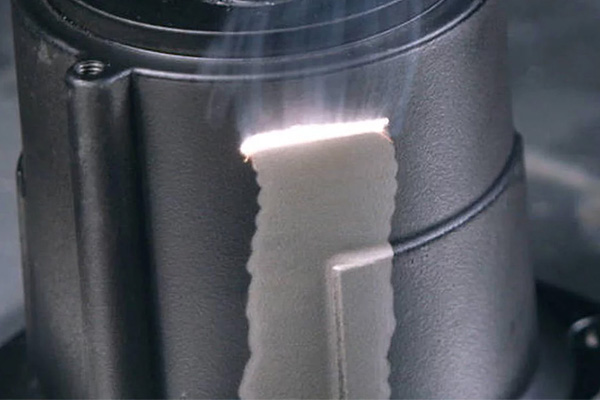

How Laser Cleaning Removes Paint

Laser paint removal works through controlled laser–material interaction, primarily involving absorption of laser energy by the paint layer rather than the substrate.

When a laser beam strikes a painted surface:

- The paint absorbs laser energy and heats rapidly

- Thermal expansion and vaporization weaken adhesion

- The paint layer is ablated, lifted, or fractured

- The substrate remains largely unaffected if parameters are correct

Unlike blasting or grinding, laser cleaning does not rely on mechanical force. This is why it can remove paint without roughening or thinning the base material, which is critical in high-value components.

Paint Types and Laser Removal Suitability

Not all paints respond to laser energy in the same way. Absorption characteristics vary widely depending on chemistry, pigments, and binders.

Laser Paint Removal Suitability by Paint Type

| Paint Type | Typical Examples | Laser Removal Suitability |

|---|---|---|

| Acrylic paints | Automotive coatings | Excellent |

| Epoxy paints | Industrial coatings | Good |

| Polyurethane paints | Aerospace coatings | Good |

| Alkyd paints | Machinery coatings | Moderate |

| Powder coatings | Industrial finishes | Moderate |

| Elastomeric coatings | Rubberized paints | Limited |

| Multi-layer systems | Primer + topcoat | Variable |

Dark-colored paints generally absorb laser energy more efficiently, while light or reflective coatings may require higher energy density or multiple passes.

Substrate Matters: What Lies Beneath the Paint

The substrate determines not only whether laser cleaning is safe, but how aggressively it can be applied.

Substrate Compatibility Overview

| Substrate | Laser Paint Removal Performance | Key Considerations |

|---|---|---|

| Carbon steel | Excellent | High tolerance |

| Stainless steel | Excellent | Reflectivity management |

| Aluminum | Good | Thermal sensitivity |

| Copper / brass | Limited | High reflectivity |

| Plastics | Poor–limited | Heat damage risk |

| Composites | Limited | Delamination risk |

Laser paint removal is most widely used on metal substrates, where thermal tolerance and absorption contrast favor controlled ablation.

Paint Thickness and Layer Structure

Laser cleaning is fundamentally a layer-by-layer process. This makes it exceptionally precise, but also introduces throughput limits.

Paint Thickness vs Practical Efficiency

| Paint Condition | Laser Paint Removal Feasibility |

|---|---|

| Thin single layer | Excellent |

| Standard automotive coating | Good |

| Multiple paint layers | Moderate |

| Thick industrial coatings | Limited |

| Heavy anti-corrosion systems | Often impractical alone |

For very thick or elastic coatings, laser cleaning is often combined with mechanical or abrasive pre-removal, followed by laser finishing in critical areas.

Selective Paint Removal: Where Laser Cleaning Excels

One of the strongest advantages of laser paint removal is selectivity.

Laser systems can be tuned to:

- Remove topcoat while preserving primer

- Strip paint from edges or weld zones only

- Create clean bonding or welding surfaces

This is extremely difficult to achieve with blasting or chemical stripping.

Applications Where Selectivity Drives Value

| Application | Benefit |

|---|---|

| Welding preparation | Clean seams without over-stripping |

| Aircraft maintenance | Preserve base material integrity |

| Mold refurbishment | Avoid dimensional change |

| Automotive repair | Localized paint removal |

In these scenarios, laser cleaning often becomes the only viable option, not merely an alternative.

Process Control and Repeatability

Laser paint removal is digitally controlled. Parameters such as power, pulse width, frequency, scanning speed, and spot size can be stored and repeated.

Why This Matters

| Aspect | Traditional Methods | Laser Cleaning |

|---|---|---|

| Repeatability | Operator-dependent | Program-controlled |

| Documentation | Minimal | Full traceability |

| Automation | Limited | Strong |

| Quality consistency | Variable | High |

This level of control is increasingly important in regulated industries.

Throughput and Productivity Considerations

Laser paint removal is not the fastest method for large, low-value surfaces.

Productivity Comparison (Indicative)

| Method | Large Area Paint Removal |

|---|---|

| Abrasive blasting | Very fast |

| Chemical stripping | Fast |

| Mechanical grinding | Medium |

| Laser cleaning | Medium–slow |

Where surface area is massive and tolerance is loose, laser cleaning may not be economically optimal as a standalone solution.

Environmental and Safety Aspects

Laser paint removal significantly reduces secondary waste but introduces laser-specific safety requirements.

Environmental Comparison

| Factor | Laser Cleaning | Chemical Stripping |

|---|---|---|

| Chemical waste | Minimal | High |

| Dust generation | Low | Medium |

| Wastewater | None | Significant |

| Fume extraction | Required | Required |

Paint vapors and particulates must be properly captured, especially when removing hazardous coatings.

Industry-Specific Realities of Laser Paint Removal

Laser paint removal is already established across multiple industries, but its role differs significantly depending on value density, tolerance requirements, and regulatory pressure. Understanding these differences clarifies where laser cleaning is practical, where it is optimal, and where it should be used only as a complementary process.

Automotive Manufacturing and Repair

In automotive production and refinishing, paint removal is rarely about stripping an entire vehicle. It is about localized precision—weld seams, repair zones, bonding areas, and defect correction. Laser cleaning excels here because it removes paint exactly where needed without thinning sheet metal or altering surface geometry.

| Automotive Task | Laser Paint Removal Value |

|---|---|

| Weld seam preparation | Excellent |

| Spot repair stripping | Excellent |

| Full-body stripping | Economically weak |

| Adhesive bonding prep | Excellent |

For full-body paint removal, abrasive or chemical methods remain faster. For precision zones, laser cleaning often becomes the preferred or even mandated method.

Aerospace and Defense Applications

Aerospace paint systems are complex, multilayered, and tightly regulated. Substrate integrity is critical, and aggressive blasting is often prohibited.

Laser paint removal is used for:

- Localized coating removal

- Corrosion inspection access

- Repair preparation without altering tolerances

| Aerospace Requirement | Laser Advantage |

|---|---|

| Substrate protection | Very high |

| Process traceability | Excellent |

| Regulatory compliance | Strong |

| Throughput priority | Secondary |

In aerospace, laser cleaning is adopted not for speed, but for risk reduction.

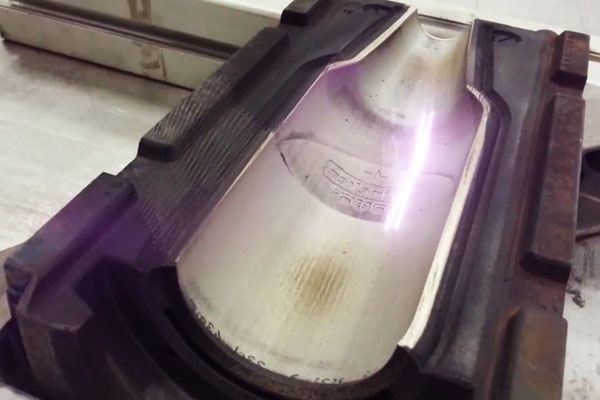

Mold, Tooling, and High-Value Equipment

Paint and coating removal from molds, dies, and tooling is extremely sensitive. Even minor dimensional changes can cause defects.

| Application | Laser Suitability |

|---|---|

| Injection molds | Excellent |

| Die casting tools | Excellent |

| Precision fixtures | Excellent |

Laser cleaning removes coatings and residues without mechanical contact, making it one of the safest options for high-value tooling.

Shipbuilding and Heavy Industry

In shipyards and heavy fabrication, paint layers are thick, elastic, and applied over massive surfaces. Here, laser cleaning faces its most visible limitations.

| Shipyard Task | Laser Paint Removal Role |

|---|---|

| Large-area stripping | Poor |

| Edge zones & weld prep | Good |

| Final surface finishing | Good |

Laser cleaning is rarely used alone. Instead, it complements blasting by handling critical zones where precision and cleanliness matter.

Laser Cleaning vs Other Paint Removal Methods: Practical Conclusions

Laser paint removal is often compared against established methods. The question is not which method works, but which method creates the most value under specific constraints.

Comparative Outcome Matrix

| Method | Substrate Damage | Waste | Precision | Scalability |

|---|---|---|---|---|

| Laser cleaning | Minimal | Very low | Very high | Medium |

| Abrasive blasting | High | High | Low | High |

| Chemical stripping | Low | Very high | Medium | Medium |

| Mechanical grinding | Medium | Medium | Low | Medium |

Laser cleaning stands out where precision and cleanliness outweigh raw speed.

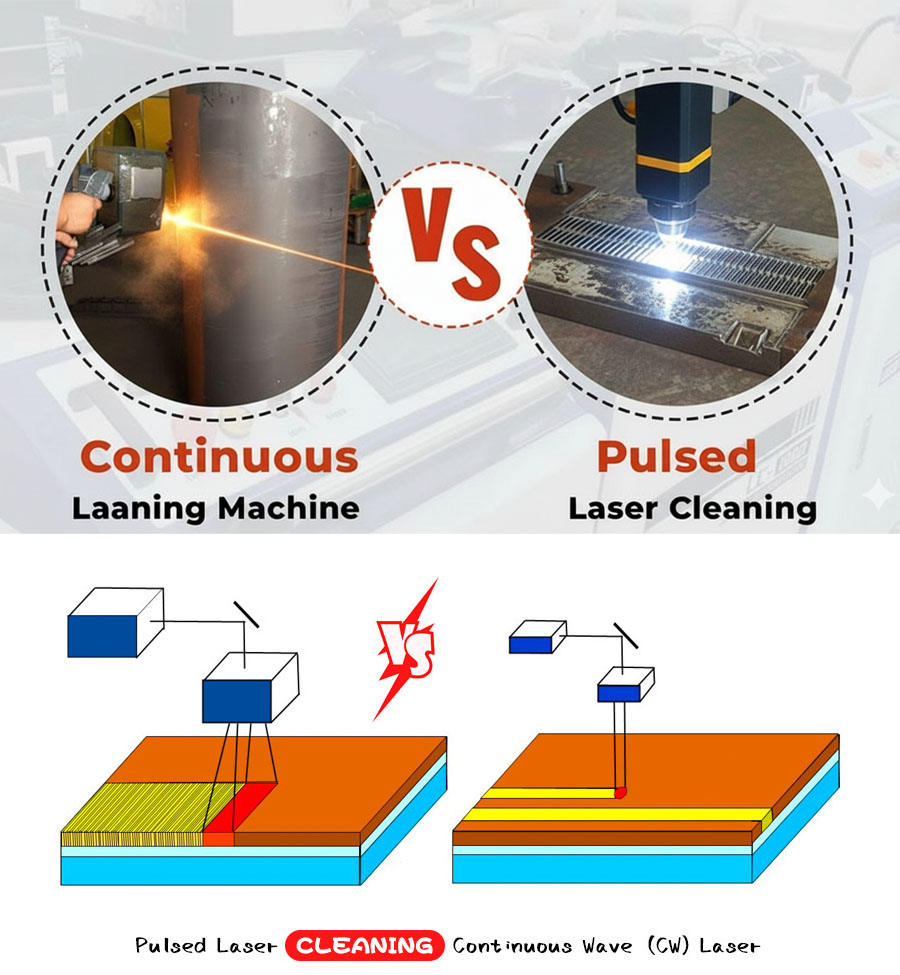

Key Process Parameters That Determine Paint Removal Success

Laser paint removal is governed by a combination of optical and thermal parameters. Incorrect settings are the most common cause of poor results.

Core Parameters Influencing Performance

| Parameter | Effect on Paint Removal |

|---|---|

| Laser power | Removal speed |

| Pulse duration | Thermal control |

| Frequency | Energy distribution |

| Scan speed | Coverage vs intensity |

| Spot size | Precision vs throughput |

Pulsed fiber lasers are generally preferred for paint removal because they deliver high peak power with lower average heat input, reducing substrate risk.

Does Laser Paint Removal Damage the Substrate?

This is the most common concern—and the most misunderstood.

When properly configured:

- The paint absorbs most of the laser energy

- The substrate reflects or dissipates residual heat

- No measurable material loss occurs

Substrate Risk by Condition

| Condition | Risk Level |

|---|---|

| Thick steel | Very low |

| Thin aluminum | Medium |

| Heat-treated alloys | Medium |

| Plastics | High |

Damage occurs primarily when:

- Power is excessive

- Scan speed is too slow

- Heat accumulation is ignored

These are process errors, not inherent flaws of laser cleaning.

Common Failure Scenarios and How to Avoid Them

| Failure Cause | Practical Consequence |

|---|---|

| Underpowered system | Inefficient stripping |

| Wrong laser type | Excessive heating |

| No fume extraction | Optics contamination |

| Expecting bulk removal | Economic disappointment |

Successful laser paint removal depends on realistic expectations and correct system matching.

Environmental and Compliance Implications

Laser paint removal reduces:

- Chemical exposure

- Secondary waste

- Water contamination

However, it still requires:

- Proper fume extraction

- Filtration for hazardous coatings

- Laser safety compliance

Final Answer: Can Laser Cleaning Remove Paint?

Yes—laser cleaning can remove paint effectively, safely, and with exceptional control, especially on metal substrates and in precision-critical applications. It is not the fastest or cheapest method for stripping massive surfaces, but it is often the best method where surface integrity, selectivity, and compliance matter.

Laser paint removal is not about replacing every traditional method. It is about doing what other methods cannot do well.

A Practical Closing Perspective

At BOGONG Machinery, we approach laser paint removal with engineering realism. We help customers identify where laser cleaning delivers clear advantages—and where hybrid or alternative methods make more sense. This ensures that paint removal is not just technically possible, but operationally and economically sound.

If you are evaluating paint removal solutions and need results without collateral damage, the right question is not “Can a laser remove paint?” but “Is laser cleaning the right tool for my specific paint and substrate?”

Talk to BOGONG Machinery to design a laser paint removal solution that works in practice—not just in theory.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com