Do and Don’ts for Laser Cleaning Machine?

Laser cleaning technology is rapidly replacing sandblasting, chemical stripping, and abrasive grinding in industrial surface treatment. Yet many companies invest in a laser cleaning machine only to discover inconsistent cleaning quality, substrate damage, excessive lens contamination, or even safety hazards. The real problem is not the laser itself—it is improper operation, incorrect parameter selection, poor maintenance discipline, and misunderstanding of laser-material interaction. A high-performance fiber laser cleaner can deliver micron-level precision and zero-contact removal, but only when it is operated within correct technical boundaries. This comprehensive guide explains exactly what you must do—and what you must never do—when operating a laser cleaning machine, ensuring safety, efficiency, equipment longevity, and maximum ROI.

The essential do’s and don’ts for laser cleaning machines revolve around five core principles: correct parameter matching to material type, strict safety compliance, proper optical system maintenance, controlled thermal management, and disciplined operational workflow. Always calibrate power, frequency, pulse width, and scanning speed to the contamination layer—not the substrate. Never operate without protective eyewear or ventilation. Keep lenses and fiber optics clean, ensure cooling systems are stable, and avoid overexposure that may alter base metal microstructure. Following these rules maximizes cleaning efficiency while preventing surface damage, safety risks, and costly downtime.

If you are using a 100W, 300W, 1000W, or even 2000W fiber laser cleaning machine—especially in industrial rust removal, mold cleaning, paint stripping, or oil decontamination—understanding these operational boundaries is non-negotiable. As a professional laser equipment manufacturer at BOGONG Machinery, we consistently observe that performance problems almost always trace back to operational mistakes rather than hardware limitations. The following technical guide will help you avoid those costly errors.

Understanding Laser Cleaning Fundamentals Before Operation

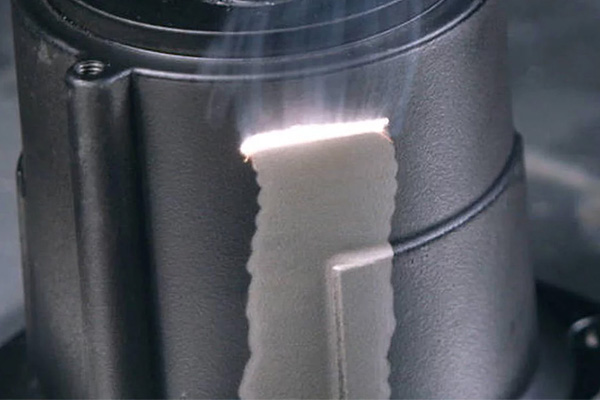

Before discussing operational discipline, it is critical to understand the core physics behind laser cleaning. Laser cleaning machines typically use pulsed fiber lasers operating at wavelengths around 1064 nm. The removal mechanism involves photothermal ablation, photomechanical shock, and plasma-induced material ejection. The contaminant layer absorbs laser energy more efficiently than the substrate, resulting in rapid heating, micro-explosion, and detachment.

Laser-material interaction depends on:

- Absorption coefficient of contamination vs. substrate

- Pulse duration (nanosecond vs. picosecond vs. continuous wave)

- Peak power density

- Spot size

- Repetition frequency

- Scanning speed

Typical Laser Cleaning Parameter Ranges

| Parameter | 100W Pulse | 300W Pulse | 1000W Pulse | 2000W Pulse |

|---|---|---|---|---|

| Average Power | 100W | 300W | 1000W | 2000W |

| Pulse Frequency | 20–200 kHz | 20–200 kHz | 20–500 kHz | 20–500 kHz |

| Pulse Width | 100–200 ns | 100–200 ns | 100–150 ns | 100–150 ns |

| Spot Diameter | 0.1–2 mm | 0.1–2 mm | 0.1–3 mm | 0.1–3 mm |

| Cleaning Width | 10–100 mm | 10–120 mm | 20–150 mm | 20–200 mm |

Selecting the wrong parameter configuration is the most common mistake in laser cleaning operations.

DO: Match Laser Parameters to Contamination Type

Not all contaminants respond the same way to laser irradiation. Rust, oil, paint, oxide scale, and carbon deposits have different absorption spectra and bonding strength.

Contaminant vs. Recommended Parameter Adjustment

| Contaminant Type | Power Level | Frequency | Scanning Speed | Risk if Overpowered |

|---|---|---|---|---|

| Light Rust | Low–Medium | Medium | High | Surface discoloration |

| Heavy Rust | Medium–High | Medium | Medium | Micro pitting |

| Paint | Medium | Low–Medium | Medium | Substrate overheating |

| Oil & Grease | Low | High | High | Smoke accumulation |

| Oxide Scale | High | Medium | Low–Medium | Base metal alteration |

The correct strategy is progressive escalation. Begin at lower power density and increase gradually.

DON’T: Assume Higher Power Means Better Cleaning

One of the most dangerous misconceptions in industrial laser cleaning is that higher wattage automatically improves productivity. In reality:

- Excessive peak power can cause substrate melting.

- Thermal accumulation can alter metallurgical properties.

- Excessive ablation generates plasma shielding, reducing efficiency.

Power density (W/cm²) matters more than total wattage. Proper beam scanning patterns optimize efficiency without overheating.

DO: Maintain Optical Components Properly

The optical path is the heart of your laser cleaning machine. Contaminant backscatter and fume particles can deposit on:

- Protective lens

- Collimator lens

- Focusing lens

- Galvo scanner window

Failure to clean optical components results in:

- Reduced beam quality

- Lower cleaning efficiency

- Increased heat on lens surface

- Permanent lens damage

Optical Maintenance Schedule

| Component | Inspection Frequency | Cleaning Method | Replacement Interval |

|---|---|---|---|

| Protective Lens | Daily | Isopropyl alcohol + lens tissue | 3–6 months |

| Focusing Lens | Weekly | Non-abrasive optical wipes | 6–12 months |

| Fiber Connector | Monthly | Dry compressed air | As needed |

| Galvo Window | Weekly | Optical cleaner spray | 12 months |

Always power off the system before servicing optical components.

DON’T: Operate Without Proper Ventilation

Laser ablation generates:

- Metal particulates

- Combustion gases

- Organic vapor

- Micron-sized debris

These airborne contaminants pose health risks and can recontaminate surfaces.

Industrial setups must include:

- Fume extraction system

- HEPA filtration

- Negative pressure airflow

- Activated carbon filters (for paint removal)

Ignoring ventilation can damage both operators and equipment.

DO: Implement Strict Laser Safety Protocols

Laser cleaning machines fall under Class 4 laser systems. Direct or reflected exposure can cause irreversible eye injury.

Mandatory safety measures:

- OD6+ rated laser protective eyewear

- Interlocked work area

- Laser safety training

- Beam path containment

- Emergency stop accessibility

Never bypass safety interlocks.

DON’T: Ignore Thermal Management

Fiber lasers rely on stable cooling systems.

Cooling requirements include:

- Industrial water chiller

- Temperature range: 20–25°C

- Clean deionized water

- Stable voltage supply

Overheating risks:

- Reduced laser lifetime

- Fiber damage

- Output instability

Cooling System Parameters

| Parameter | Recommended Range |

|---|---|

| Water Temperature | 20–25°C |

| Water Conductivity | < 5 µS/cm |

| Flow Rate | 10–20 L/min |

| Ambient Temperature | 15–30°C |

DO: Train Operators on Material Response

Different metals react differently:

- Aluminum reflects more

- Carbon steel absorbs more

- Stainless steel oxidizes differently

- Copper requires wavelength sensitivity

Operator training must include surface testing and sample trials.

DON’T: Overlap Beam Excessively

Excessive scan overlap leads to:

- Surface overheating

- Microstructural changes

- Heat tint formation

- Reduced surface roughness control

Maintain consistent scan strategy and controlled overlap ratio (typically 10–30%).

DO: Perform Routine Preventive Maintenance

Routine inspection checklist:

- Cable integrity

- Fiber bending radius

- Galvo alignment

- Grounding verification

- Emergency stop functionality

Preventive Maintenance Checklist

| Inspection Item | Frequency |

|---|---|

| Laser Output Stability | Monthly |

| Electrical Wiring | Quarterly |

| Cooling System Flush | 6 months |

| Software Calibration | Annually |

DON’T: Use Laser Cleaning on Inappropriate Materials Without Testing

Certain materials require caution:

- Thin aluminum sheets

- Heat-treated components

- Plastic substrates

- Coated optics

- Composite materials

Always conduct a small test area first.

DO: Optimize ROI Through Process Planning

Laser cleaning improves ROI when:

- Chemical waste disposal is high

- Abrasive media cost is significant

- Labor costs are rising

- Environmental regulations are strict

Cost Comparison (Estimated)

| Method | Consumables | Environmental Cost | Maintenance | Surface Damage Risk |

|---|---|---|---|---|

| Sandblasting | High | High | Medium | High |

| Chemical Stripping | Medium | Very High | High | Medium |

| Laser Cleaning | Low | Very Low | Low | Low |

Laser cleaning becomes economically superior over medium-to-long-term production cycles.

DO: Calibrate Software Profiles Properly

Modern laser cleaning machines include preset parameter profiles.

Best practice:

- Create material-specific presets

- Lock critical parameter ranges

- Document optimal settings

- Standardize production procedures

Avoid manual parameter guessing during production runs.

DO: Maintain Proper Electrical Supply

Voltage fluctuations can damage laser sources.

Requirements:

- Stable 220V / 380V supply

- Voltage regulator

- Proper grounding

- Surge protection

Electrical instability reduces fiber lifespan.

DO: Monitor Surface Quality After Cleaning

Inspection methods:

- Visual inspection

- Surface roughness measurement

- Microscopy

- Adhesion testing (for coating prep)

Laser cleaning is frequently used before painting or welding; therefore, surface integrity is critical.

Conclusion: Precision Determines Performance

Laser cleaning machines are highly efficient, environmentally friendly, and precise surface treatment tools—but only when operated within disciplined technical boundaries. The difference between flawless cleaning and substrate damage is often a matter of parameter control, safety compliance, and preventive maintenance. Companies that treat laser cleaning as a precision process rather than a brute-force tool achieve superior results, longer equipment lifespan, and higher ROI.

Talk Directly With Our Laser Cleaning Engineers at BOGONG Machinery

If you are selecting, upgrading, or optimizing a laser cleaning machine, we are ready to help. At BOGONG Machinery, we provide not only high-performance pulse fiber laser cleaning systems from 100W to 2000W, but also full technical support, parameter optimization guidance, and after-sales engineering assistance.

Contact us today to receive:

• Professional model recommendation

• Customized cleaning parameter suggestions

• ROI calculation support

• Factory-direct pricing

• Technical training materials

BOGONG Machinery

Precision Laser Solutions for Industrial Surface Treatment

Let’s make your cleaning process safer, smarter, and more profitable.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com