Do Laser Cleaning Machines Really Work

After seeing a technician wave a laser over a rusty mold and watch the rust vanish, I wrote in my notebook: “This is either magic or madness.” Years later, having visited dozens of facilities, I conclude: yes, they do work — but only when you respect their limits, choose parameters wisely, and maintain discipline.

This blog is not a sales pitch. It’s a deeper exploration: how laser cleaning succeeds, where it fails, and what separates scenic demos from dependable systems in real industrial life. If you’re shopping a laser cleaning system or just skeptical, this is for you.

What “Works” Means: Beyond Clean Surfaces

To answer “Do they really work?”, we must define success in several dimensions:

- Contaminant removal — does it clean rust, paint, oil, oxidation, adhesives to acceptable levels?

- Substrate integrity — does it avoid harming the base material (melting, pitting, heat damage)?

- Repeatability & reliability — does it perform consistently over months, not just in demos?

- Operational viability — does it integrate into production, maintain uptime, and avoid stealth degradation?

- Economic & maintenance tradeoffs — is the total cost acceptable given alternatives?

In many lab demos, you’ll see pristine coupon cleaning. But in a dusty shop, under full shift loads, with variable parts — that’s where many systems fall short. A laser cleaning machine truly works when it survives those stresses.

How the Technology Works (Deep Mechanisms)

To see how laser cleaning “works,” we must understand the physical forces at play. The literature identifies three primary mechanisms — and each carries tradeoffs.

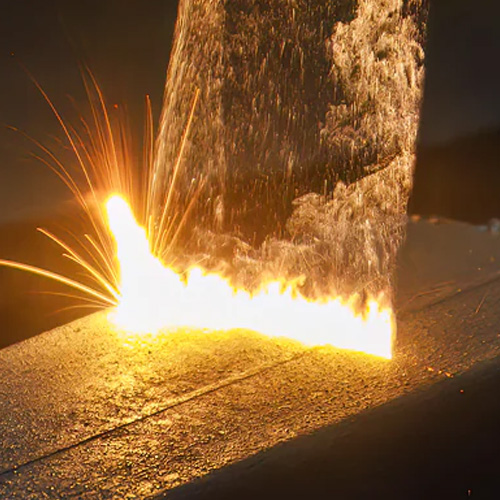

1. Thermal Ablation / Evaporation

The laser heats the contaminant layer so fast that it vaporizes—turns into gas or plasma—without giving heat time to diffuse into the substrate. This is the cleanest mechanism but demands tight control of energy (fluence) and pulse duration.

2. Thermal Stress / Spallation

Rapid heating creates stress waves in the layers, especially at interfaces. The mismatch in expansion can cause cracks or delamination of the coating and peel it off. This works well for thicker or tougher adhesion layers that pure ablation might struggle with.

3. Plasma / Shock Waves

At high intensity, plasma can form above the surface, generating micro-explosions or shock waves that further eject contaminants. This helps with stubborn deposits or micro-particles bonded tightly.

Importantly: which mechanism dominates depends on contaminant type, thickness, laser parameters (wavelength, pulse width, overlap) and substrate material. The “sweet spot” is having enough energy to activate one or more of those mechanisms for the contaminant, while staying below damage thresholds of the base.

Where It Does Work Impressively — Real Use Cases

Laser cleaning isn’t just theory; it has real industrial successes. Some example domains:

- Rust, oxides, scale removal on metals. Many shops now use fiber lasers to strip oxide or residual coatings before welding or recoating.

- Paint and coating removal in controlled sectors (aircraft, automotive) where selective removal is critical.

- Cultural heritage restoration — cleaning stone, bronze, or artifacts with minimal mechanical stress.

- Precision cleaning in microelectronics or optics — removing micro debris or films without contact.

- Composite prep / adhesive removal — selectively removing adhesive or contamination layers prior to bonding.

In research, scientists have shown that laser cleaning can remove black sulphur encrustation from silver surfaces using excimer lasers, leaving minimal substrate impact. Also, recent reviews enumerate how laser cleaning is used for metals, nonmetals, semiconductors, each with its own parameter regimes.

These successes happen when system design, part design, and maintenance all align.

Where It Doesn’t Work (or Struggles) — Real Pitfalls

Not all jobs are suitable. Here’s where many “laser fails” hide:

Thick, multi-layer or heavy coatings

If contaminants are very thick (multi-millimeter), energy demands escalate; you might need many passes, increasing heat load, or resort to pre-cleaning methods.

Hidden or shadowed geometries

Laser must “see” the surface. Undercuts, internal cavities, overhangs — areas blocked from beam paths — become blind spots.

Substrate sensitivity / low damage margin

Thin metals, delicate alloys, composites, or heat-sensitive materials have narrow tolerances. It’s easy to cross into damage.

Reflective materials

Highly reflective surfaces (polished metals) can reflect energy away or even damage optics if not handled.

Optics fouling & drift

In real environments, soot, vapor, micro-debris accumulate on optics windows or mirrors. Beam energy deteriorates. Many systems degrade silently unless cleaned and calibrated regularly.

Cooling / thermal stability limits

If your cooling or temperature control is weak, beam quality will drift or power drop mid-job. The best machine can’t compensate poor thermal design.

Cost, maintenance, operator skill

High capital cost, optics replacement, system alignment, operator training — these hidden costs often overwhelm budgets in poorly scoped projects.

Many critical blogs (e.g. on disadvantages of laser cleaning) warn that its effectiveness depends heavily on power, pulse duration, material properties, and that for large-scale or bulk jobs other methods may still dominate.

What It Takes for a Laser Cleaning Machine to Really Work in Your Shop

From countless audits and installations, I can distill what separates machines that work from ones that disappoint. These are “depth practices,” not just “tips.”

1. Parameter Window & Safety Margin

Don’t buy a laser that just barely meets your spec. Leave headroom in power, cooling, beam stability so you can absorb drift, dust, operator variation.

2. Real-part trials under worst-case conditions

Coupons and clean demo parts are fine, but demand performance on your worst parts, geometry, ambient heat, dust, and over full shift.

3. Optics and beam path maintenance plan

Schedule regular cleaning, protective windows, contamination monitoring. The beam path is your nervous system — if it degrades, everything falls off.

4. Cooling and thermal stability design

Cooling is the silent backbone. Design for worst-case ambient temperature, clogged filters, drift. Use active feedback if possible.

5. Monitoring, logging & metrics

Track beam power, cleaning throughput, drift over time, maintenance logs. Detect small declines early.

6. Operator training, safety, fallback plans

Eyes & skin protection, interlocks, failsafes, fallback cleaning methods (if laser fails or part area unreachable).

7. Modular & upgradeable architecture

Replace beam heads, optics modules, cooling subsystems — don’t lock yourself into a monolithic, throwaway design.

If those elements are in place, a laser cleaning machine will really work — and remain a dependable asset, not a showpiece.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com