Does a laser rust remover also remove paint?

When investing in a laser rust remover, many industrial users assume it is designed only for corrosion. However, in real-world manufacturing and maintenance environments, metal surfaces rarely suffer from rust alone. They are often covered with multilayer paint systems, primers, powder coatings, epoxy films, or protective sealants. If a laser rust removal system cannot also handle paint removal, its industrial value becomes limited. On the other hand, excessive laser power applied to paint could risk substrate overheating or coating carbonization. Understanding whether a laser rust remover can remove paint—and how effectively—requires analyzing laser-material interaction at the molecular and thermal levels.

Yes, a properly configured pulsed fiber laser rust remover can also remove paint. Laser cleaning systems operate based on selective energy absorption and photothermal ablation, which allows them to remove organic coatings such as paint, epoxy, powder coating, and primers in addition to rust. However, removal efficiency depends on coating thickness, color, composition, pulse energy, and scanning parameters. Industrial-grade pulsed laser systems are highly effective for paint stripping when properly optimized.

To fully understand this capability, we must examine coating composition, laser absorption characteristics, thermal dynamics, layer thickness influence, and substrate protection mechanisms.

Laser-Material Interaction: Why Paint Can Be Removed

Laser cleaning works because contaminants absorb laser energy differently than the underlying metal. Rust (iron oxide) absorbs strongly at 1064 nm wavelength, but many paints—especially dark or pigmented coatings—also absorb laser energy efficiently.

\

Mechanisms of Paint Removal

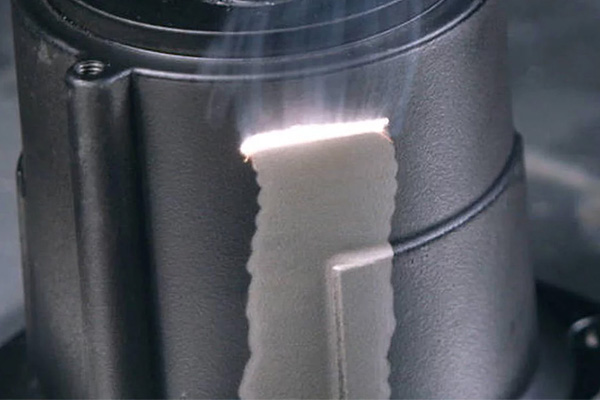

When the laser pulse contacts paint:

- Organic binders rapidly heat and decompose

- Pigments absorb energy and fracture

- Microplasma forms beneath the coating

- Rapid thermal expansion causes delamination

- Coating lifts from substrate

Unlike sandblasting, which erodes mechanically, laser stripping detaches coatings via thermal shock and vaporization.

Absorption Characteristics Comparison

| Material | Laser Absorption at 1064 nm | Removal Efficiency |

|---|---|---|

| Iron Oxide | High | Very High |

| Black Paint | High | Very High |

| Red/Brown Paint | Moderate–High | High |

| White Paint | Moderate | Moderate |

| Clear Coating | Lower | Moderate |

Darker coatings typically remove more efficiently due to higher absorption.

Rust vs. Paint: Performance Differences

Rust removal and paint stripping differ in energy requirements.

Typical Energy Requirements

| Material | Required Fluence (J/cm²) |

|---|---|

| Light Rust | 0.2–0.6 |

| Thick Rust | 0.6–1.2 |

| Thin Paint (≤100 µm) | 0.5–1.0 |

| Thick Epoxy (>300 µm) | 1.0–2.0 |

Paint generally requires similar or slightly higher energy density than rust.

Industrial pulsed systems with adjustable pulse energy (1–20 mJ) are capable of handling both.

Multi-Layer Coating Systems

Industrial surfaces often contain:

- Primer

- Intermediate epoxy layer

- Topcoat

- Clear sealant

Laser cleaning removes coatings layer-by-layer rather than aggressively stripping all layers simultaneously.

Layer Removal Comparison

| Cleaning Method | Control Over Layer Removal |

|---|---|

| Sandblasting | Low |

| Chemical Stripping | Moderate |

| Laser Cleaning | High |

Laser systems allow selective removal—useful when only the top layer needs to be removed.

Substrate Protection During Paint Removal

A major advantage of laser paint stripping is substrate preservation.

Sandblasting Risks

- Metal thinning

- Surface pitting

- Abrasive embedment

- Dimensional distortion

Laser Advantages

- Non-contact process

- Adjustable pulse energy

- Minimal base metal removal (<5 µm typical)

- Controlled heat input

Properly configured pulsed fiber lasers remove paint without melting the metal.

Heat-Affected Zone (HAZ) Considerations

Paint removal generates more organic vapor than rust removal. However, pulsed systems limit thermal accumulation.

HAZ Comparison

| Method | Heat Impact |

|---|---|

| Chemical Stripping | None (chemical risk) |

| Sandblasting | Mechanical stress |

| CW Laser | Moderate HAZ |

| Pulsed Fiber Laser | Minimal HAZ |

Pulsed systems with nanosecond pulses minimize substrate heating.

Cleaning Speed Comparison

Paint thickness significantly affects removal speed.

Approximate Cleaning Speed (1000W Pulsed Laser)

| Coating Type | Speed |

|---|---|

| Thin Paint (≤100 µm) | 2–3 m²/hour |

| Medium Epoxy (200 µm) | 1–2 m²/hour |

| Thick Industrial Coating (>400 µm) | 0.5–1 m²/hour |

Sandblasting may remove thick coatings faster but with lower precision.

Smoke and Fume Management

Paint removal generates:

- Organic vapors

- Carbonized particulates

- Pigment dust

Industrial laser systems must include:

- High-capacity fume extraction

- HEPA filtration

- Activated carbon filters for organic gases

Proper extraction ensures safe operation.

Application Case Studies

Automotive Restoration

Laser removed both rust and multiple paint layers from classic car panels without warping thin sheet metal.

Aerospace Maintenance

Selective paint removal allowed stripping of topcoat without affecting primer or substrate.

Shipyard Spot Repair

Laser systems used for localized paint and rust removal without abrasive contamination.

Environmental Comparison

| Factor | Sandblasting | Chemical Stripping | Laser Cleaning |

|---|---|---|---|

| Waste Media | High | None | None |

| Chemical Disposal | None | High | None |

| Surface Damage | Moderate | Low | Very Low |

| Airborne Dust | High | Low | Controlled |

Laser cleaning is environmentally superior for paint stripping.

Limitations of Laser Paint Removal

Laser paint stripping may be less effective when:

- Coatings are extremely thick (>1 mm)

- Highly reflective metallic paints reduce absorption

- Large structural surfaces require maximum speed

In such cases, hybrid approaches may be considered.

Parameter Optimization

Critical parameters for paint removal:

- Pulse energy

- Frequency

- Scan speed

- Spot overlap

- Defocus adjustment

Improper settings may cause:

- Surface discoloration

- Incomplete stripping

- Excess carbonization

Industrial systems provide preset modes for different coating types.

Cost Efficiency

Although laser systems require higher initial investment, they eliminate:

- Abrasive media costs

- Chemical stripping agents

- Waste disposal

- Surface rework

Over 3–5 years, laser paint removal becomes economically competitive.

Technical Comparison Summary

| Criteria | Laser Rust Remover | Sandblasting |

|---|---|---|

| Rust Removal | Excellent | Excellent |

| Paint Removal | Excellent (controlled) | Fast but aggressive |

| Substrate Protection | Superior | Moderate |

| Environmental Impact | Low | High |

| Precision | High | Low |

Laser rust removers are multifunctional systems capable of paint stripping when properly configured.

Final Technical Conclusion

A laser rust remover is not limited to corrosion removal. Industrial pulsed fiber laser cleaning systems are fully capable of removing paint, primers, powder coatings, and organic films. Performance depends on coating composition, thickness, and laser parameter optimization. Compared to traditional sandblasting, laser paint removal offers superior precision, reduced substrate damage, and improved environmental compliance.

When engineered correctly, a single laser cleaning system can handle rust removal and paint stripping within the same platform, making it a versatile investment for industrial maintenance and manufacturing.

Let’s Talk About Your Application

At BOGONG Machinery, we design industrial pulsed fiber laser cleaning systems optimized for both rust removal and paint stripping. If you need to evaluate coating thickness, metal type, or cleaning speed requirements, our engineering team can recommend the appropriate pulse configuration and power level for your specific application.

Contact BOGONG Machinery to discuss your project and discover how one precision laser system can handle both corrosion and coating removal efficiently and safely.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com