Finding a Laser Cleaning Machine Supplier in Jinan: Local vs. International Sourcing

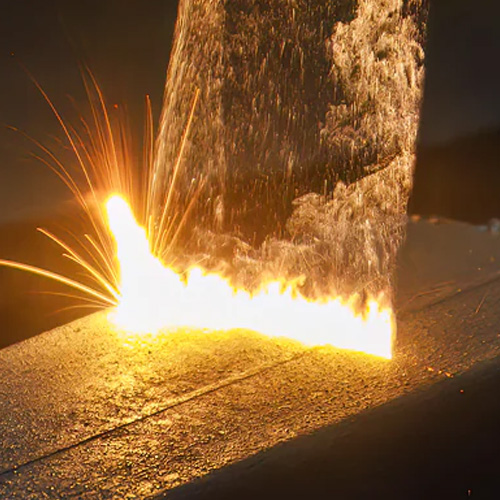

When you’re standing in your factory, staring at a mold encrusted with carbon, you don’t want your laser machine to be another source of stress. You want a partner you can trust—who understands your time zone, parts, emergencies. That’s why sourcing locally (for you, in Jinan) often outperforms the “cheaper overseas” dream.

In this guide, I walk you through the high-stakes, human side of choosing a laser cleaning machine supplier—especially in Jinan, China. I’ll expose hidden costs, emotional risks, and strategic advantages that more superficial blog posts often leave out. At the end, you should see not just which supplier to pick, but how to think about sourcing in a resilient, B2B way.

Why Jinan Matters in Laser Cleaning Supply Chains

Before comparing local vs international, let me explain why Jinan is a strong node in the laser equipment ecosystem—and why you should care.

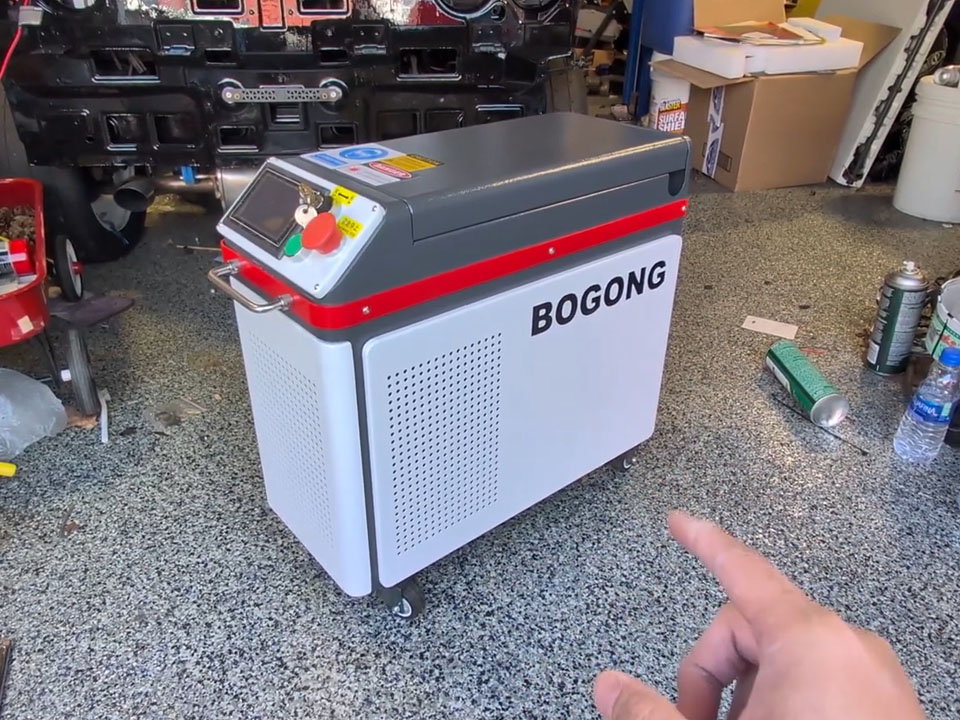

- Jinan is home to numerous established laser machinery firms: Jinan BOGONG Machinery Co.ltd produces laser cleaning, welding, marking machines.

- Shandong Fridas laser equipment co.ltd. offers a wide variety of laser cleaning machines (from 100 W to multi-kilowatt) and often lists FOB offers from their China factory. ([Fridas laser][2])

- Jinan D. Ventus Mechanical Equipment Co., Ltd. also makes laser cleaning machines (both CW and pulse) among its line. ([D. Ventus][3])

- Jinan Starma Intelligent Tech offers 200 W pulsed cleaning machines and emphasizes fast delivery from its Jinan base. ([Starma CNC Laser][5])

These are not one-off listings — they represent a cluster of laser machine expertise, supply chains, spare parts, local staff, and manufacturing infrastructure in Jinan. That gives you a head start if you choose a Jinan supplier.

The Deep Trade-Offs: Local (Jinan) vs. International Supplier Sourcing

Let me not hide the tension. There is no perfect answer. But having lived through numerous machine purchases and support contracts, here are the deeper trade-offs you must weigh.

| Dimension | Local Supplier in Jinan | International Supplier (Outside Jinan / Offshore) |

|---|---|---|

| Lead time & iteration speed | Faster turnaround for custom tweaks, rapid prototyping, faster repairs | Slower because of shipping, customs, time zone delays |

| Service / onsite support | Easier to dispatch engineers on short notice; parts often local or within accessible distance | Longer travel, delays, perhaps higher cost of importing spare parts |

| Communication clarity & cultural alignment | Fewer translation barriers, more face-to-face visits, better mutual accountability | Greater risk of miscommunication, expectations mismatch |

| Logistics cost & customs risk | Lower cross-border shipping, simpler customs, easier packaging iterations | Higher freight, customs duty, risk of misclassification or delays |

| Inspection & factory audit access | You can visit the factory quickly, audit process, quality control | Distant factories are harder to verify; virtual audits are weaker surrogates |

| Economies of global scale | May be a bit more expensive per unit for small runs, but you gain flexibility | May have stronger scale advantages for mass production, but trade-off is rigidity |

| Innovation & cross-market insights | Local firms often absorb market feedback faster, respond more flexibly | International firms sometimes lead in “bleeding edge” features or proprietary tech |

| Risk of dependency | If Jinan supply is disrupted (e.g. local regulations, power, logistics), you might be vulnerable | International suppliers diversify risk but may also face geopolitical or currency risks |

From real experiences, I’ve seen that the difference between a “cheap overseas machine” and a “reliable local machine” often lies in how many back-and-forths you must do to get things right. With Jinan suppliers, you have the proximity advantage.

How to Vet a Jinan Supplier Deeply (So Local Doesn’t Mean “Cheap and Shaky”)

Picking a local supplier is not a guarantee — you must vet them rigorously. Here’s a deeper, human-centered checklist they rarely publish, but I’ve seen separate good deals from bad ones.

1. Ask About Past Failures & Learning Stories

Don’t just ask them what’s perfect. Ask: “Tell me a time a machine you shipped failed in the field. How did you respond? What did you change in your next units?” Their answer reveals maturity and accountability.

2. Quality & Calibration Transparency

Demand documentation: beam divergence, alignment tolerance, drift over time (e.g., after 200 hours). Ask to see the optical test benches, historic logs. If they resist, that’s a red flag.

3. Spare Parts Strategy in Jinan

Which parts are stocked locally? Mirrors, protective windows, fiber cables, cooling modules? If they say “we ship from Shanghai / Beijing / overseas” for everything, you lose the advantage.

4. Factory Visits & Shop Floor Walkthroughs

A quick factory tour can show you cable routing cleanliness, dust control, optics lab, alignment jigs, QA benches. If the optics area is dusty, that’s a warning sign.

5. Support SLA & Escalation Paths

If a machine fails, what’s the guaranteed response time (4 h, 24 h, 48 h)? Is there a local technician in your region (or accessible from Jinan)? Get this in writing.

6. Audit the Supply Chain

Where do they source their fiber lasers, mirrors, power supplies? If crucial modules are imported and fragile, import risks creep back in. A Jinan supplier that sources core parts locally or regionally is more robust.

7. Reference Clients Nearby

Ask for clients in your same country or region. Better if they are in your industry. Visit them if possible, inspect a machine they’ve run 1+ years in real use.

Narrative: When a Jinan Supplier Became the Lifeline

I once worked with a mid-sized parts manufacturer in Southeast Asia. They ordered a laser cleaning machine from a large U.S. brand because of prestige. But after three months, when optics fogged weirdly and drift grew, the time to get a site engineer from the U.S. was measured in weeks. Meanwhile, a small team in Jinan was able to propose an optics retrofit, ship local spares, and within 10 days have their machine running again. The Jinan supplier became their de facto backup provider. The moral: it’s not just who builds the machine well, it’s who responds when your production is halted.

Practical Steps to Source from Jinan (Your Action Guide)

Here’s how I’d walk in your shoes if I were sourcing:

- Make a short list of Jinan firms: from searches above (Bogong, Fridas, D. Ventus, Starma)

- Request detailed spec sheets + full beam path diagrams + drift logs

- Ask for a customer sample in your industry to test

- Visit the factory (or remote video) and audit optics, dust control, QA

- Negotiate spare parts coverage, support SLA, warranty, with financial teeth

- Start with a pilot or smaller unit to see real performance in your environment

- Log performance, drift, issues—and feed that learn back into future orders

Final Reflection: Local Supplier Doesn’t Mean Low Quality — If You Build Safeguards

The reason I advocate preferring Jinan is not sentimental — it’s strategic. When everything is complex — optics, drift, alignment, environmental stress — proximity and responsiveness save more time (and money) than a discount on price. But to reap that advantage, you must treat a local supplier with the same scrutiny as any international brand.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com