-

+86 156 6587 0861

-

Shunhua Road, Jinan City, Shandong

Guides & Tutorials

Step-by-step guides and tutorials to help you master laser cleaning techniques, optimize performance, and ensure safe, effective operation.

Laser Cleaning Machine Cost: Complete Price Analysis 2026

In 2025, Laser cleaning has become one of the most popular and demanding technologies in the world.

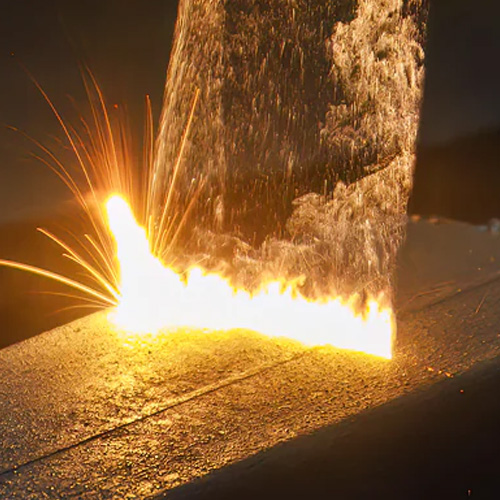

Advantages of Using Laser Cleaning Machines

More and more people like to use laser cleaning machine remove painting, rust, etc for their project. This technology offers a modern approach to removing contaminants without the need for harsh chemicals or abrasive methods. In this article, we’ll explore the advantages of using laser cleaning machines, particularly focusing on their effectiveness and versatility. What is a Laser Cleaning Machine? A laser cleaning machine adopt laser beams to remove unwanted materials from surfaces. This process is known as laser ablation, where the laser’s energy breaks down and vaporizes contaminants without damaging the underlying material. This precise method of cleaning is suitable for a wide range of applications, from industrial uses to delicate restoration projects. How Does It Work? The working principle of a laser cleaning machine is to use high-energy laser beams to irradiate the surface of…

Finding a Laser Cleaning Machine Supplier in Jinan: Local vs. International Sourcing

In this guide, I walk you through the high-stakes, human side of choosing a laser cleaning machine supplier—especially in Jinan, China.

China vs. Germany vs. USA: Which Laser Cleaning Machine Is Right for Your Business

In many articles, you’ll find tables — “German machines are premium,” “Chinese machines are cheap,” “U.S. machines are innovative.” But no buyer ever succeeded by tables alone. What wins is contextual wisdom.

Your Ultimate Guide to Importing a Laser Cleaning Machine from China: 5 Things You Must Know

If you're considering importing a laser cleaning machine from China, the savings can be tempting — but the pitfalls are real. In this guide, I’ll walk you through five critical areas you must understand (and manage) so your import doesn’t turn into a mess or a money trap.

How to Choose the Right Power for Laser Cleaning Machines

Power is one of the foundational decisions in laser cleaning. Choose too low, and you underperform. Choose too high (or mis-matched), and you risk damage, waste, cost, or brittleness.

What Can a 300W Laser Cleaner Do

We’ll go beyond the marketing hype to examine real capability, strengths, limitations, and what to expect when you use a 100 W laser cleaner across those use cases you care about: mold cleaning, rust, paint, welding prep, precision parts, electronics, relics, etc.

How Much Does a Laser Cleaning Machine Cost

In this article I’ll walk you through the real cost ranges (with real market data), explain the hidden cost drivers, help you see where many buyers get burned, and arm you to build a credible budget — not a wild guess.

Do Laser Cleaning Machines Really Work

This blog is not a sales pitch. It’s a deeper exploration: how laser cleaning succeeds, where it fails, and what separates scenic demos from dependable systems in real industrial life.

Best Practices for Operating and Maintaining a Laser Cleaning Machine

If you want your laser cleaning machine not just to run, but to run well for years, you need practices rooted in respect for optics, thermal systems, and human fallibility.

How to Choose the Right Laser Cleaning Machine for Your Application

Choosing a laser cleaning machine isn’t just about wattage or fiber vs CO₂. It’s about matching your messy reality — your parts, your environment, your team, your growth path

Air-Cooled vs. Water-Cooled Laser Cleaning Machines: Pros and Cons

If you pick the “wrong” cooling method, your laser system may underperform, throttle, or become a maintenance headache you regret for years. So let’s go deeper — not just listing pros and cons