How to Choose the Right Laser Cleaning Machine for Your Application

“We bought what looked perfect on paper — 500 W, fiber, turnkey. Yet six months in, the cooling system betrayed us, optics fouled, and operators were complaining of inconsistent results.” That’s not a rare story. It’s the kind of cautionary tale I’ve seen too many times.

Choosing a laser cleaning machine isn’t just about wattage or fiber vs CO₂. It’s about matching your messy reality — your parts, your environment, your team, your growth path — with a machine that can live through months of dust, misalignment, change orders, and operator turnover. In this article, I want to take you behind the scenes — to the real levers and mental models that separate machines you regret from ones you live with.

Start With Clarity: Your Application Landscape

No successful purchase happened without deep clarity about what you really need. Here’s how to start thinking:

- List your part types & materials Are most of your parts steel, aluminum, composites, or mixed materials? Do you have delicate substrates (thin metals, coated surfaces) or robust ones?

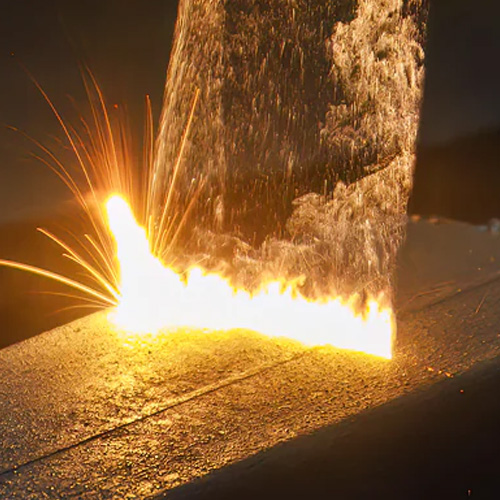

- Catalog your contaminants Rust, oxidation, paint, grease, coatings, mold release, scale — each behaves differently under laser. Some require higher energy, some require gentler pulses.

- Measure the worst-case thickness & distribution How deep is the coating or rust you need to remove? Uniform or spotty? The thicker or heavier the deposit, the higher your demands on energy and beam control.

- Define your throughput & shift demands Are you cleaning a few parts intermittently, or running full-shift, high-volume cycles? The more continuous demand you have, the more margin you’ll need.

- Survey the environment & infrastructure Ambient temperature, dust, humidity, floor space, power availability, cooling capacity — all of these cost you in the real world.

- Think about change & flexibility Will your part mix change? Will you add new shapes or materials in 12 months? Don’t lock yourself into a machine that can’t adapt.

This reality audit gives you the foundation. Without it, you risk overbuying, underperforming, or being forced into workarounds.

Core Dimensions to Balance: Beyond Specs

Once you have your application map, here are the key dimensions you must balance — with deeper nuance than most comparisons offer:

1. Energy + Power vs Duty Cycle

Wattage isn’t everything. It’s what you do with that wattage, how you deliver it, and whether your machine can sustain it over time.

- A 500 W machine might handle short bursts, but struggle under sustained use if cooling or optics drift.

- Your duty cycle (how much of each minute you can run at full power) often matters more than peak wattage.

- Also consider pulse energy, repetition rate, overlap, scanning strategy — these define how you convert that wattage into material removal.

If your cleaning demands are bursty, a system with high peak but limited thermal margin might suffice. But if you need continuous cleaning, you’ll want machine specs that deliver stable performance under load.

2. Delivery System: Handheld, Fixed, Robotic

How the laser beam reaches the part matters as much as beam quality.

- Handheld systems give flexibility, especially when parts are large, immobile, or varied.

- Fixed/gantry systems provide more stability, repeatability, and safety if parts can be positioned.

- Robotic (automated cells) deliver high throughput and consistency — but require care around fixturing, calibration, fallback paths, and maintenance.

Your choice here should reflect your process layout, variation, operator skill, and willingness to build guard cages or cells.

3. Cooling, Thermal Stability & Drift Margins

This is where many systems fail over time.

- Look for cooling systems (air, liquid, hybrid) whose margin remains under worst-case ambient conditions.

- Ask: how does the machine perform when filters clog, temperature rises, or fans degrade?

- Thermal drift can shift focus, change beam alignment, or warp optics over time.

A “safe” machine gives you headroom to absorb real-word stress. A “just enough” machine will leave you chasing drift and rework.

4. Optics, Beam Quality & Protection

Even if your laser source is great, optics fail or degrade fastest in real environments.

- Protective windows or sacrificial optics help keep contamination off critical elements.

- Beam delivery (fiber, mirrors, galvanometers) should be robust, serviceable, and protected.

- Choose systems with modular optics paths or easy cleaning and alignment operations.

Your optics are often the first bottleneck in poor systems. Build in maintainability and replaceability.

5. Safety, Guarding & Usability

No machine is useful if it’s too dangerous or too finicky for your team.

- Class 4 lasers demand interlocks, enclosures, beam stops, safety interlocks, shielding, and training.

- Human-machine interface (HMI), parameter presets, error handling, and fallback modes combine to define how usable the machine is.

- Think of usability under stress: dirty rooms, rushed operators, partial visibility. The best machine lets your team operate safely and quickly without “tricks” or hacks.

6. Total Cost of Operation (TCO) & Life Cycle Thinking

Your decision should lean on long-term cost, not just purchase cost.

- Spare parts, optics replacement, maintenance intervals, calibrations

- Downtime costs when cooling fails, optics misalign, or parts drift

- Consumables (filters, protective windows, cooling fluids, etc.)

- Training, operator turnover, remote support

- Depreciation & upgrade paths — machines age; having a path to upgrade or replace subsystemly is a plus

A laser that looks cheap up front but kills you with downtime or hidden costs becomes a liability.

Mental Models & Guardrails I Use (So You Don’t Buy the Wrong One)

Here are heuristics and guardrails I’ve developed over years advising and auditing laser purchases:

- Design for your worst month, not your average. The machine should survive your hottest, dustiest, highest-demand month without breaking down.

- Always ask for your worst-case part trial. Coupons are fine, but real geometry + real coatings + real ambient = the truth best test.

- Margin matters more than specs. If a machine barely meets your spec on paper, it will struggle in reality. Look for extra headroom.

- Track drift & degradation. After a few months, optics shift, coatings accumulate, alignment creeps. Ask vendors how their systems cope or self-calibrate.

- Favor modularity. Replace optics paths, beam heads, cooling modules without scrapping the whole system. A modular machine adapts better.

- Plan fallback paths. If the laser can’t reach a hidden pocket, plan how you’ll adapt (fixtures, alternative cleaning, secondary methods).

- Think of operators, not just engineers. If your team struggles with calibration chores, your machine will be underutilized. Usability is a deciding factor.

Example Walkthrough: Picking a Machine for a Tool Shop

Let me walk you through how I would reason this in a real scenario — to make these ideas concrete.

Scenario

You run a tooling shop, cleaning molds and dies. You have:

- Al molds coated with occasional oxide or residual release film

- Some stain, some old plating, but generally moderate thickness

- Moderate volume, mostly batch work

- Ambient shop (sometimes warm), some dust

Approach

- Application audit You note that parts are delicate at edges, often variable shapes, occasionally full-face surfaces.

- Power & energy You need enough energy to remove coatings but not so much to risk heat damage. Maybe a mid-power pulsed fiber unit (300-500 W class) gives good balance.

- Beam delivery A handheld or light-gantry system seems ideal because molds move, shapes vary. You don’t want a rigid robotic cell.

- Cooling margin Shop temps reach 35 °C in summer. Choose cooling (air or hybrid) that keeps thermal stability even at that load.

- Optics protection & service Pick a machine that includes easy optics cleaning, protective windows, and modular paths.

- Usability & safety The machine must allow operators to switch presets (e.g. “light clean,” “deep clean”) without reprogramming every time. Good interlocks and enclosures help.

- TCO & support Check spare availability, service network, calibration services, expected lifetime of key optics.

If I were to pick today, I’d lean toward a 300-500 W pulsed fiber, handheld + gantry combo, with modular optics, robust cooling, and vendor service backing. That gives flexibility now and headroom for volume growth.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com