How to Choose the Right Power for Laser Cleaning Machines

“When we bought a 500 W unit thinking it would ‘just cover everything,’ we found for many parts we were overdriving, burning edges, while for some rusty jobs it still struggled. The sweet spot isn’t “more”: it’s the right.” That kind of regret happens when teams let specs rule instead of letting real needs guide.

Power is one of the foundational decisions in laser cleaning. Choose too low, and you underperform. Choose too high (or mis-matched), and you risk damage, waste, cost, or brittleness. In this post, I’ll walk you through how to think about power not as a headline number but as a lever — one that must be tuned to your parts, contaminants, environment, and growth path.

The Meaning of “Power” — What You Must Understand First

Before you pick 100 W, 300 W, or 1,000 W, it helps to understand what “power” really means in the context of laser cleaning, and what else sits upstream or downstream of that number.

- Average vs. peak power vs. pulse energy — A 100 W pulsed system may deliver different peak energy pulses depending on frequency, pulse width, and duty cycle.

- Power density (irradiance) — How much power is concentrated into the spot or beam path matters as much as total wattage. A lower power laser with tighter focus and better optics may match or compete with a higher power laser with poor optics.

- Thermal margin, cooling, and stability — A laser’s wattage must be supported by cooling, thermal design, optics stability, and drift control. A “nominal” power rating is only as good as the system that sustains it.

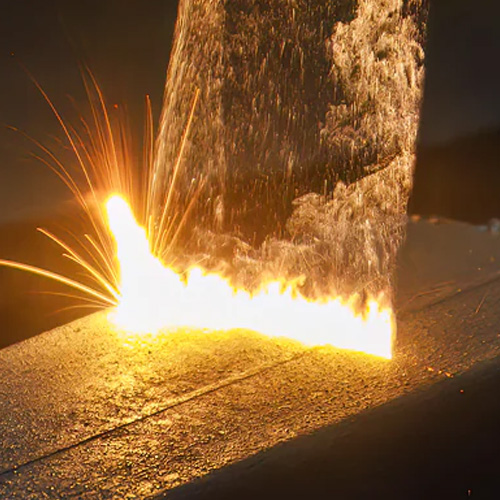

- Contaminant thresholds vs substrate limits — The optimal power must drive the contaminant removal threshold (ablation, stress delamination, etc.) without crossing the substrate’s damage threshold.

So when someone says “a 200 W laser is good,” you must mentally deconstruct what that means in their system: how tight the beam, how clean the optics, how stable the cooling, how forgiving the substrate.

Key Decision Dimensions: Mapping Power to Application

To choose the right power, you must align on these dimensions — and understand how each constrains your wattage choice.

1. Contaminant Type, Thickness & Adhesion Strength

- Thin residual films, oxidation, light rust, light paint/coating → lower power may suffice

- Thick paint, heavy rust, multilayer coatings, baked-on scale → higher power or repeated passes will be needed

- Strong adhesion or bonding (e.g. weld spatter, enamels) demands higher energy per unit area

A vendor guide suggests that lasers from 100 W to 2,000 W are differentiated by how “fat layers” or thick contaminants are handled. ([Baison][2])

2. Part Size, Geometry & Accessibility

- Small, intricate parts with tight curves, delicate edges: you may not benefit from high wattage unless the beam is very well controlled

- Large flat surfaces or big panels: higher wattage helps to sweep fast

- Shadowed or recessed areas: your beam may need to travel at an angle or bounce mirrors, which reduces effective energy — you’ll need extra margin

Adapt your nominal power upward if geometry or parts layout imposes path losses or uneven exposure.

3. Throughput / Cycle Time & Duty Cycle

- If your cleaning is occasional or small-scale, you’re less punished by slower sweeps; a modest power laser can work

- If your process must meet cycle times, you need enough wattage (and thermal stability) to hit throughput goals

- Beware duty cycle limitations: many systems rate “peak” power but limit continuous operation. Always ask for sustained performance, not just bursts.

4. Substrate Material & Sensitivity

- Soft or heat-sensitive metals, thin metals, or composite substrates impose tighter constraints on maximum energy

- Some substrates reflect more (so optical design matters more)

- If your substrate cannot tolerate lateral heat diffusion, you must limit power and manage cooling carefully

5. Optics, Beam Delivery & Losses

- Mirror losses, beam splitting, window absorption, dust buildup — these eat your “usable” power

- Even a 300 W laser may deliver only 80% or less to the surface if optics are not pristine

- You need margin: nominal wattage minus optical system losses gives you your “usable headroom”

6. Cooling, Stability & Environmental Conditions

- Ambient temperature, ventilation, vibration, dust load, optics drift — all reduce your effective usable power margin

- In hot environments or dusty shops, a system with just enough power may fail or degrade

- Strong cooling, feedback control, stability design gives you more consistent usable wattage in practice

A Spectrum of Power Recommendations (for Real Use Cases)

Below is a rough mapping (from observed vendors & published guides) of how power corresponds to classes of use. It’s not gospel — your specific parameters may shift your “band” — but it helps frame what’s realistic.

| Application / Scenario | Suggested Power Class | Notes / Caveats |

|---|---|---|

| Light surface oxide, residue, mold release, delicate parts | 100 W – 200 W | Requires good optics, slow sweep, tight control |

| Moderate rust, painted surfaces on small to medium parts | 200 W – 500 W | Good balance of speed and margin |

| Heavy coatings, large panels, general industrial cleaning | 500 W – 1,500 W | Requires strong cooling, stable optics, aggressive design |

| Structural, thick rust or coatings, full-scale industrial work | ≥ 1,500 W (CW or high-power pulsed) | Needs robust thermal architecture, safety systems, and strong margins |

Sources: one vendor guide divides into low / mid / high power categories based on application.

Another company recommends that 100 W–500 W pulsed lasers suffice for precision and cleaning tasks, while continuous wave lasers often exceed 1,000 W for heavy industrial tasks.

Real-World Story: When “Better Spec” Backfired

Let me tell you a cautionary tale:

A fabrication shop purchased a 1,000 W laser to “future-proof.” On paper, it seemed safe: they’d never exceed lower power needs, and the margin was big. But in practice:

- The cooling system was overtaxed under shop heat, causing thermal drift

- For small parts, the beam was overkill: slight misalignment burned edges

- Optics dust buildup degraded performance significantly, eating into the headroom they thought they had

- Operators lost ability to tune low-power finesse, because the system was built around high power

They ended up “derating” the system to run at lower power levels anyway, but with more risk. A 300 W system with better optical and thermal design would have outperformed in many of their real jobs — and cost less, been more stable, and been more forgiving.

That’s why “bigger is safer” is a seductive lie unless you manage all downstream systems well.

Checklist to Validate a Power Choice (Before You Commit)

Here’s a mental / practical checklist you should run for any power spec you’re considering — call it “stress-test your wattage decision”:

- Test real worst-case parts under your ambient, geometry, and dust conditions.

- Ask for sustained power performance — not just peak specs.

- Model optical losses — from mirrors, windows, dust — subtract from your headroom.

- Simulate heat rise and margin drift — what happens if ambient goes up 10 °C, or if filters clog?

- Check safety and substrate thresholds — ensure you have buffer between removal threshold and damage threshold.

- Evaluate cooling & thermal stability specs — are they engineered for your environment?

- Plan for periodic recalibration & optics maintenance — drifting optics should not collapse your usable power margin.

- Ensure modular upgrade path — if your workload increases later, can you scale or add a higher-power head without replacing the whole system?

If any of those checks make you nervous, your chosen “power” is probably too close to the edge.

Final Reflections: Power as a Means, Not a Badge

Power is tempting to fetishize: “I need a 1,500 W laser to show I can do anything.” But in reality, the best laser cleaning setups are balanced suites: optics, cooling, stability, usability, drift tolerance, and real-world margin.

A well-tuned 300 W or 500 W system, used carefully, can outperform a sloppy 1,500 W machine any day — especially over months and years. Your goal isn’t max wattage. It’s enough wattage, reliably delivered, without collateral damage or hidden costs.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com