Is Laser Cleaning a Profitable Business?

Starting a laser cleaning business looks deceptively simple: buy a laser cleaner, find rusty or dirty metal, charge by the hour, and collect profit. That simplicity is exactly why many people underestimate both the opportunity and the risk. On one side, promotional videos suggest effortless margins, zero consumables, and endless demand. On the other, skeptics warn that machines are expensive, jobs are inconsistent, and customers still default to sandblasting or chemicals. The reality sits between these extremes—and the difference between a profitable laser cleaning business and a struggling one comes down to business model design, market positioning, cost structure, and operational discipline rather than the laser itself.

Yes, laser cleaning can be a profitable business—but only when it is positioned as a value-added industrial service with clear use cases, disciplined pricing, high utilization of equipment, and a well-defined target market. Profitability is not automatic; it depends on choosing the right laser type, controlling capital expenditure, securing repeat customers, and selling outcomes (precision, cleanliness, compliance, downtime reduction) rather than “laser hours.”

If you are considering laser cleaning as a standalone service business, a side operation, or an extension of an existing fabrication, maintenance, or surface-treatment company, this guide will walk you through the economics in detail. We will break down costs, revenue models, market demand, pricing logic, risk factors, and scaling strategies step by step—so you can evaluate profitability with numbers, not hype.

Step 1: Understand What Kind of “Laser Cleaning Business” You Are Building

The first mistake new entrants make is assuming there is only one type of laser cleaning business. In reality, there are several distinct models, each with different profitability dynamics, risk profiles, and capital requirements. Before running any numbers, you must decide which model fits your background, market access, and tolerance for uncertainty.

The most common model is on-site industrial service. In this model, you travel to the customer’s facility or job site with a portable laser cleaning machine and charge by the hour, by the day, or by the project. Typical clients include factories, shipyards, power plants, steel structure installers, and maintenance contractors. This model benefits from low customer switching (once approved, you are often reused) and high perceived value, but it requires strong sales skills, flexible scheduling, and tolerance for irregular work.

A second model is in-house contract cleaning, where customers ship parts to your workshop. This is common for mold cleaning, precision parts, weld preparation, or restoration components. The advantage is process control, repeatability, and easier scaling through fixtures and automation. The downside is logistics cost and narrower job scope. Profitability here depends heavily on repeat orders and efficient workflow design.

A third model is vertical integration, where laser cleaning is not sold as a service at all, but embedded into another business—such as fabrication, coating, welding, remanufacturing, or restoration. In this case, laser cleaning improves margins indirectly by reducing rework, improving quality, or differentiating your main offering. This is often the most reliable path to profit, even if it is not marketed as “laser cleaning services.”

Finally, there is the niche premium model, focused on high-value, low-volume work: aerospace components, heritage restoration, battery manufacturing, or high-precision molds. These markets pay for documentation, repeatability, and risk reduction, not speed alone. Entry barriers are higher, but margins can be substantial.

Understanding which model you are pursuing is critical, because the same laser cleaner that is profitable in one model can be unprofitable in another.

Step 2: Break Down the Real Startup Costs (Beyond the Machine Price)

Most discussions about profitability fixate on the price of the laser cleaning machine itself. While that is the largest single expense, it is not the only meaningful cost—and ignoring the rest leads to unrealistic ROI expectations.

Below is a realistic startup cost structure for a small to mid-scale laser cleaning business.

| Cost Category | Typical Range (USD) | Notes |

|---|---|---|

| Laser cleaning machine | $20,000 – $120,000 | Depends on CW vs pulsed, power level, brand |

| Fume extraction system | $3,000 – $15,000 | HEPA + pre-filter; critical for real jobs |

| Power & electrical setup | $1,000 – $5,000 | Single-phase vs three-phase matters |

| Safety equipment | $500 – $2,000 | Laser goggles, curtains, signage |

| Transport & packaging | $1,000 – $5,000 | Vehicle mods, crates, shock protection |

| Training & trial materials | $500 – $2,000 | Sample testing, parameter development |

| Marketing & sales | $1,000 – $10,000 | Website, demos, travel, lead generation |

What matters most is not minimizing these costs, but aligning them with your revenue model. For example, a 60,000 pulsed laser with good control may outperform a100,000 high-power CW laser if your jobs are precision-focused and repeatable. Conversely, under-investing in fume extraction often leads to failed jobs, customer complaints, or regulatory issues—directly harming profitability.

A useful rule of thumb: the machine should represent no more than 60–70% of your total initial investment. If it is higher, you are likely underestimating the operational reality.

Step 3: Understand the Revenue Side—How Laser Cleaning Actually Gets Paid

Laser cleaning businesses do not make money by “turning on the laser.” They make money by solving problems that customers already pay to solve—often inefficiently—with other methods. Your pricing power comes from replacing or improving those methods.

There are four dominant pricing structures in the market:

- Hourly rate: Common for on-site work, typically ranging from 80 to300 per hour depending on region, industry, and specialization.

- Daily rate: Often used for industrial shutdowns or maintenance windows; simplifies billing and protects utilization.

- Per-part or per-area pricing: Used in workshops or contract cleaning; encourages efficiency.

- Outcome-based project pricing: Premium model where you sell a result (e.g., coating-ready surface, defect-free weld prep).

Below is a simplified comparison of revenue potential.

| Pricing Model | Typical Rate | Pros | Cons |

|---|---|---|---|

| Hourly | $100–$250/hr | Easy to explain | Caps upside; client watches the clock |

| Daily | $800–$2,000/day | Predictable income | Requires full-day utilization |

| Per-part | Highly variable | Scales with efficiency | Needs stable process |

| Project-based | High margins | Value-focused | Requires strong credibility |

The most profitable laser cleaning businesses evolve away from pure hourly billing toward value-based or repeat contract pricing. Hourly work is often a starting point, not the destination.

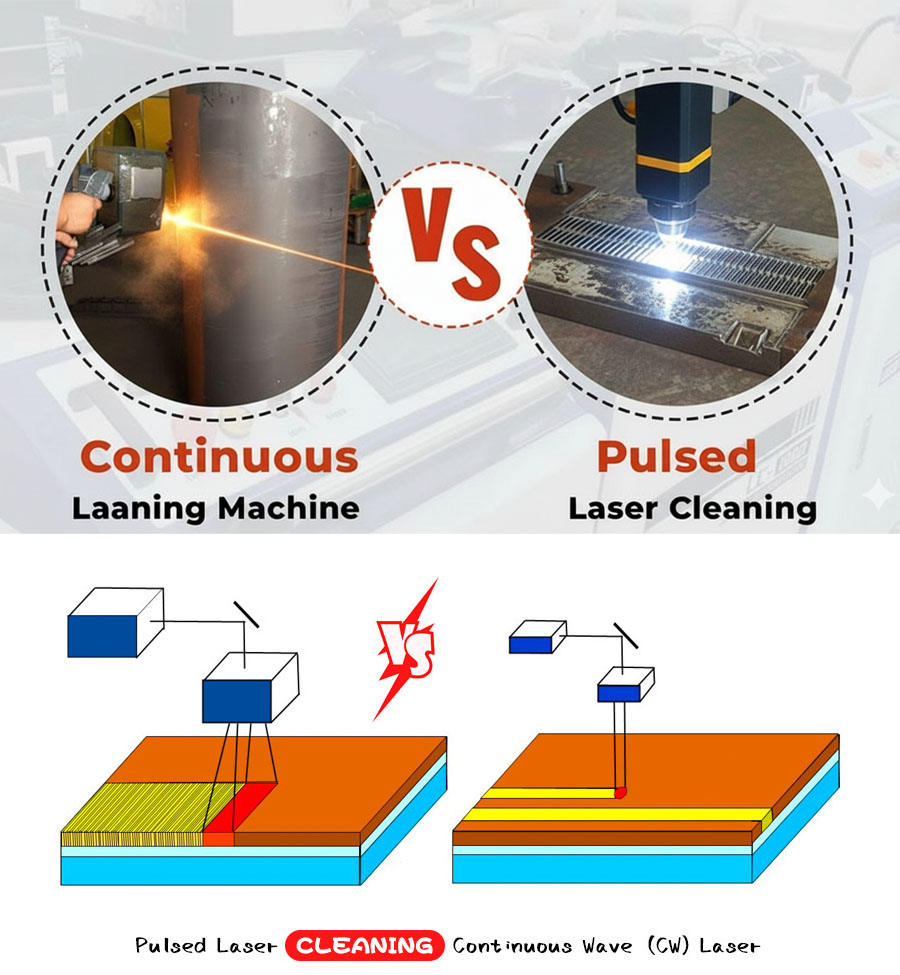

\ Pulse VS Continuous Laser Cleaning Machine[/caption]

Pulse VS Continuous Laser Cleaning Machine[/caption]

Step 4: Calculate Utilization—The Hidden Determinant of Profit

Laser cleaning machines do not make money when they are idle. Utilization rate—the percentage of available working time that the machine is actually billable—is the single most important profitability variable.

Consider this simplified annual model:

| Parameter | Low Utilization | Healthy Utilization |

|---|---|---|

| Machine cost | $60,000 | $60,000 |

| Useful life | 5 years | 5 years |

| Annual depreciation | $12,000 | $12,000 |

| Billable hours/year | 300 hrs | 1,200 hrs |

| Depreciation per hour | $40/hr | $10/hr |

The same machine can be either barely profitable or highly profitable depending on utilization. This is why many successful operators start laser cleaning as an add-on to an existing business, where the machine can be used frequently without needing to “find” work from scratch.

A realistic target for a standalone service business is 800–1,200 billable hours per year. Below that, profit margins shrink rapidly unless pricing is very high.

Step 5: Operating Costs—Lower Than You Think, But Not Zero

Laser cleaning is often marketed as “no consumables.” That is misleading. While there is no abrasive media, there are still operating costs that must be budgeted.

| Operating Cost | Typical Impact |

|---|---|

| Electricity | Low (often <$5/hr) |

| Filters (fume extraction) | Medium; recurring |

| Optics maintenance | Low–medium |

| Labor | Medium; skilled operator |

| Transport & setup | Medium for on-site jobs |

Compared with sandblasting or chemical stripping, operating costs are usually lower and more predictable. However, ignoring filter replacement or optics care can lead to downtime and expensive repairs—erasing profits quickly.

Step 6: Market Demand—Where Laser Cleaning Actually Sells

Laser cleaning is not equally profitable in all markets. Demand clusters around specific pain points.

High-demand sectors include:

- Industrial maintenance (rust, oxide, coatings)

- Welding and fabrication (pre- and post-weld cleaning)

- Mold and tool cleaning

- Shipbuilding and offshore structures

- Power generation and heavy industry

- Automotive and battery manufacturing

Low-demand or price-sensitive sectors include:

- Low-value mass production

- DIY or consumer markets

- Situations where blasting is already optimized and cheap

Profitability increases when customers care about precision, downtime, compliance, or surface integrity. If price per square meter is the only decision factor, laser cleaning struggles to compete.

Step 7: Risk Factors That Kill Profitability

Several predictable mistakes cause laser cleaning businesses to fail:

- Buying oversized equipment without secured demand

- Competing purely on price with blasting services

- Poor parameter control leading to inconsistent results

- Underestimating sales effort and long sales cycles

- Treating laser cleaning as a commodity instead of a solution

Laser cleaning is a consultative sale. Customers often need education and trials before committing. Businesses that budget time and resources for this phase survive; those expecting instant bookings usually do not.

Step 8: Scaling the Business—From One Machine to a Real Operation

Once a laser cleaning business reaches stable utilization, scaling becomes possible—but only with process discipline. Scaling paths include:

- Adding a second machine for parallel jobs

- Automating repeat work with fixtures or robots

- Specializing in one industry and becoming the “go-to” provider

- Bundling laser cleaning with inspection, coating, or repair services

The most successful operators document parameters, standardize quoting, and invest in customer relationships rather than chasing one-off jobs.

Step 9: So—Is Laser Cleaning a Profitable Business in Reality?

Laser cleaning is not a guaranteed money machine, but it is absolutely a viable and often highly profitable business when approached correctly. It rewards operators who understand industrial pain points, control utilization, and sell value instead of hours. It punishes those who treat the laser as a magic tool and ignore fundamentals like market fit, pricing, and workflow.

In practical terms, laser cleaning is most profitable when:

- The machine is used frequently

- Jobs are repeatable or contract-based

- Customers value quality and precision

- The service is integrated into a broader offering

Thinking About Turning Laser Cleaning Into a Real Business?

If you are evaluating laser cleaning as a business—whether as a standalone service or as part of an existing operation—the most important step is choosing the right machine for your market, not the biggest or cheapest one. At BOGONG Machinery, we work with operators, contractors, and manufacturers to match laser cleaning systems to real-world business models, not just technical specs. If you want to run the numbers honestly, test your applications, and build a laser cleaning operation that makes sense long-term, reach out to BOGONG Machinery and start with a practical discussion—not a sales pitch.

If you want, I can continue with Part 2, focusing specifically on real profit case studies, pricing examples, and a step-by-step break-even calculation so you can model your own scenario precisely.

Real Profit Case Studies, Pricing Examples, and a Step-by-Step Break-Even Model for a Laser Cleaning Business

We established that laser cleaning can be profitable, but only under specific structural conditions: correct positioning, disciplined utilization, and value-based selling. In this second part, we move from theory to numbers. This section is intentionally practical. We will look at real-world profit logic through representative case studies, concrete pricing examples, and a full break-even calculation you can adapt to your own situation. The goal is not to make laser cleaning look easy; the goal is to make the economics transparent enough that you can decide—confidently—whether this business makes sense for you.

Step 10: Case Study Logic — What Profitable Laser Cleaning Actually Looks Like on the Ground

Instead of naming specific companies, which often hides more than it reveals, we analyze three representative business archetypes commonly seen in the market. These are composites built from real operators’ numbers and outcomes.

Case A: Mobile Industrial Maintenance Service (On-Site)

This is the most common entry point. The operator owns one portable laser cleaning unit and services factories, steel structures, and maintenance shutdowns.

Profile

- Equipment: 1 × 1,500 W CW handheld laser cleaner

- Initial investment (all-in): ~$75,000

- Target clients: factories, power plants, steel fabricators

- Pricing model: daily rate + travel

Typical Pricing

- Day rate: 1,200–1,800/day

- Average billed days/month: 8–12

- Annual billed days (realistic): ~110 days

Revenue & Cost Snapshot (Annual)

| Item | Amount (USD) |

|---|---|

| Gross revenue | $165,000 |

| Electricity & filters | $4,000 |

| Labor (owner-operator) | $0–$40,000* |

| Travel & logistics | $12,000 |

| Maintenance & optics | $3,000 |

| Depreciation (5 yrs) | $15,000 |

| Estimated operating profit | $90,000–$110,000 |

*Owner-operators often pay themselves from profit; employees change the model.

Key Insight:

Profitability here does not come from constant work. It comes from high day rates and customers who value downtime reduction. The risk is seasonality and sales effort. Operators who fail usually underestimate how long it takes to fill the calendar.

Case B: Workshop-Based Precision Cleaning (Molds / Parts)

This model targets repeatable, controlled jobs with inbound logistics.

Profile

- Equipment: 1 × 200–300 W pulsed laser cleaner

- Initial investment: ~$45,000

- Target clients: mold makers, injection molding factories

- Pricing model: per mold / per part

Typical Pricing

- Mold cleaning: 150–600 per mold

- Average molds/day: 4–6

- Annual working days: ~220

Revenue & Cost Snapshot

| Item | Amount (USD) |

|---|---|

| Gross revenue | $180,000 |

| Electricity & filters | $3,000 |

| Labor (1 technician) | $45,000 |

| Maintenance | $2,500 |

| Depreciation | $9,000 |

| Estimated operating profit | ~$120,000 |

Key Insight:

This is one of the most stable laser cleaning business models. Lower headline prices, but very high utilization and repeat clients. Precision and documentation matter more than speed.

Case C: Integrated Fabrication / Coating Business (Hidden Profit Model)

Laser cleaning is not sold separately; it improves margins elsewhere.

Profile

- Equipment: 1 × 1,000 W pulsed or CW system

- Initial investment: ~$60,000

- Use: weld prep, coating prep, rework reduction

- Pricing model: bundled into fabrication/coating contracts

Economic Impact

- Rework reduction: 30–50%

- Coating failures reduced

- Faster turnaround

Financial Effect

- Direct revenue: $0 (laser not billed)

- Indirect margin gain: 80,000–150,000/year

Key Insight:

This is the least risky way to profit from laser cleaning. Customers never question price because they never see it as a separate line item.

Step 11: Pricing Laser Cleaning — How Professionals Avoid the “Too Expensive” Trap

New entrants often hear, “Your price is higher than sandblasting.” Profitable operators respond by changing the comparison, not lowering the price.

Below is how professional pricing logic works.

Cost Comparison Customers Actually Care About

| Factor | Sandblasting | Laser Cleaning |

|---|---|---|

| Surface damage | Possible | Minimal |

| Masking required | High | Low |

| Waste disposal | High | Low |

| Downtime | Longer | Shorter |

| Rework risk | Medium | Low |

| Documentation | Rare | Easy |

Laser cleaning is rarely sold as “cheaper.” It is sold as lower total cost of ownership for the job.

A Simple Value-Based Pricing Formula

Laser Cleaning Price = (Cost of Alternative Method) − (Savings + Risk Reduction) + Premium

If blasting costs a customer 5,000 including downtime and rework risk, charging3,500–$4,500 for laser cleaning is entirely reasonable—even if your internal cost is much lower.

This is where profitability comes from: understanding the customer’s cost structure, not your own machine cost.

Step 12: Break-Even Calculation — A Model You Can Reuse

Let’s build a conservative, step-by-step break-even model for a first laser cleaning machine.

Assumptions

- Machine + setup: $60,000

- Useful life: 5 years

- Annual fixed costs (insurance, marketing, misc.): $6,000

- Variable cost per billable hour: $10

- Average billing rate: $150/hour

Annual Fixed Cost

- Depreciation: $12,000

- Fixed overhead: $6,000

- Total fixed cost: $18,000

Contribution Margin per Hour

- Revenue/hour: $150

- Variable cost/hour: $10

- Contribution margin: $140/hour

Break-Even Hours per Year

18,000 ÷140 ≈ 129 hours/year

That is less than 11 hours per month to cover fixed costs.

Everything beyond that is profit (before labor).

This is why laser cleaning can be profitable—and also why people fail: they never get past the first few hundred billable hours.

Step 13: Why Some Laser Cleaning Businesses Fail (Even with Good Equipment)

Failure patterns are remarkably consistent:

- Buying first, selling later

- No defined target industry

- Competing only on hourly rate

- Poor demos and no sample validation

- Treating laser cleaning as a commodity

Laser cleaning is not self-selling technology. It rewards operators who act like industrial problem solvers, not tool renters.

Step 14: Long-Term Profit Strategy — From Job-to-Job to System Business

The highest-earning laser cleaning operators all converge on the same strategy:

- Fewer clients, more repeat work

- Standardized parameters and SOPs

- Bundled services (inspection, prep, coating, repair)

- Clear specialization (e.g., molds, weld prep, corrosion control)

Laser cleaning becomes more profitable as it becomes less generic.

Final Verdict: Is Laser Cleaning a Profitable Business—Really?

Yes—but only for operators who:

- Understand utilization economics

- Choose the right business model

- Sell outcomes, not machine time

- Integrate laser cleaning into a broader value chain

Laser cleaning is not a shortcut to easy money. It is a high-leverage tool in the hands of disciplined operators. Those who treat it like a business system build durable profit. Those who treat it like a gadget usually exit quietly.

Thinking Seriously About the Numbers?

If you are evaluating laser cleaning as a business or as a strategic upgrade to your existing operation, the smartest move is to start with your use cases and your market—not generic promises. At BOGONG Machinery, we work with real operators to match laser cleaning systems to actual revenue models, utilization targets, and growth plans. If you want to run your own break-even scenario, test real samples, or design a laser cleaning setup that makes financial sense from day one, reach out to BOGONG Machinery and have a practical conversation grounded in numbers, not hype.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com