Is Laser Cleaning More Effective Than Sandblasting?

Sandblasting has dominated industrial surface preparation for more than a century. From rust removal and paint stripping to surface roughening for coatings, abrasive blasting became the default choice because it is simple, fast, and relatively inexpensive to deploy. Laser cleaning, by contrast, is a comparatively new entrant—often perceived as cleaner, more precise, and more advanced, but also more expensive and complex. This contrast naturally leads to a critical question for manufacturers, maintenance contractors, and asset owners alike: is laser cleaning actually more effective than sandblasting, or is it simply different?

Laser cleaning is more effective than sandblasting in applications where precision, substrate protection, repeatability, and environmental control are critical; sandblasting remains more effective where large surface areas, thick contamination, and lowest unit cost dominate. Effectiveness, therefore, depends not on absolute superiority, but on fit between process and application.

What “Effective” Really Means in Industrial Cleaning

Before comparing technologies, it is essential to define what “effective” means in an industrial context. Effectiveness is often oversimplified as removal speed, but in practice it is multidimensional.

Core Dimensions of Cleaning Effectiveness

| Dimension | Why It Matters |

|---|---|

| Removal completeness | Ensures coating adhesion or inspection |

| Substrate integrity | Prevents damage and rework |

| Process consistency | Enables repeatable quality |

| Throughput | Affects productivity |

| Environmental impact | Drives compliance |

| Total cost | Determines long-term viability |

A process that is fast but damages the substrate may be ineffective in high-value applications. Conversely, a slower process that preserves geometry and metallurgy may be far more effective overall.

How Sandblasting Achieves Effectiveness

Sandblasting removes contaminants through mechanical impact. Abrasive particles strike the surface at high velocity, fracturing rust, paint, or scale and physically eroding the substrate if exposure continues.

Strengths of Sandblasting

| Attribute | Practical Advantage |

|---|---|

| High material removal rate | Excellent for thick coatings |

| Large-area coverage | Efficient for bulk work |

| Simple technology | Easy to deploy |

| Low equipment cost | Low entry barrier |

Sandblasting is particularly effective for:

- Heavy corrosion

- Thick paint layers

- Large structural components

Its effectiveness lies in brute-force efficiency.

Inherent Trade-Offs of Abrasive Impact

The same mechanical force that removes contaminants also:

- Roughens surfaces

- Removes base material

- Generates dust and waste

- Requires extensive containment and cleanup

These trade-offs are acceptable in some industries, but prohibitive in others.

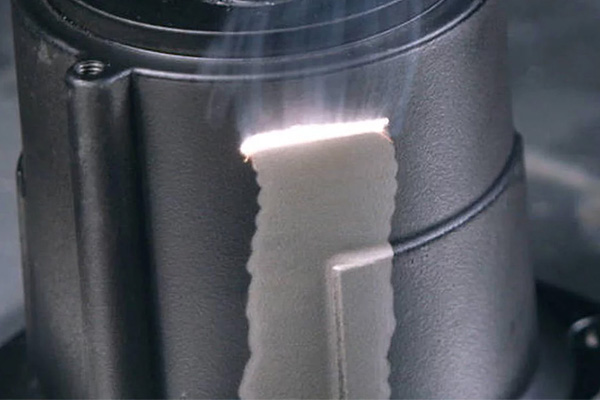

How Laser Cleaning Achieves Effectiveness

Laser cleaning removes contaminants through controlled energy absorption, not mechanical force. Laser energy is absorbed preferentially by the contaminant layer, causing it to ablate or detach while minimizing substrate interaction.

Strengths of Laser Cleaning

| Attribute | Practical Advantage |

|---|---|

| Non-contact process | No mechanical damage |

| Selective removal | Layer-by-layer control |

| Minimal waste | Cleaner environment |

| Digital control | High repeatability |

Laser cleaning is particularly effective for:

- Thin rust or oxide layers

- Paint removal without substrate loss

- Precision surface preparation

- Sensitive or high-value components

Its effectiveness lies in precision and control, not brute force.

Substrate Protection: A Major Divider of Effectiveness

One of the clearest distinctions between laser cleaning and sandblasting is how each process interacts with the base material.

Substrate Impact Comparison

| Aspect | Laser Cleaning | Sandblasting |

|---|---|---|

| Material removal | Minimal | Significant |

| Surface roughening | Controlled | Aggressive |

| Dimensional change | Negligible | Possible |

| Microcracking risk | Very low | Present |

For components where dimensional accuracy, fatigue life, or surface integrity matters, laser cleaning is often categorically more effective.

Precision and Selectivity

Laser cleaning can be programmed to remove only what is necessary.

Selectivity Capabilities

| Task | Laser Cleaning | Sandblasting |

|---|---|---|

| Edge-only cleaning | Excellent | Poor |

| Weld seam prep | Excellent | Fair |

| Multi-layer control | Possible | Not possible |

| Partial coating removal | Controlled | Uncontrolled |

Sandblasting removes everything it contacts. Laser cleaning removes only what you target.

Throughput and Area Coverage

Effectiveness shifts when surface area increases.

Area-Based Productivity Comparison

| Scenario | Laser Cleaning | Sandblasting |

|---|---|---|

| Small precision parts | High | Low |

| Medium components | Moderate | High |

| Massive structures | Low | Very high |

For ship hulls, bridges, or large tanks, sandblasting remains more effective in terms of square meters per hour.

Environmental and Regulatory Effectiveness

Modern definitions of effectiveness increasingly include compliance and sustainability.

Environmental Impact Comparison

| Factor | Laser Cleaning | Sandblasting |

|---|---|---|

| Dust generation | Very low | Very high |

| Waste disposal | Minimal | Significant |

| Media consumption | None | Continuous |

| Regulatory burden | Lower | Higher |

In regulated environments, laser cleaning’s effectiveness includes risk reduction, not just material removal.

Operator Dependence and Consistency

Effectiveness over time depends on consistency.

| Factor | Laser Cleaning | Sandblasting |

|---|---|---|

| Operator skill sensitivity | Medium | High |

| Process repeatability | High | Low |

| Automation readiness | Strong | Limited |

Laser cleaning maintains effectiveness across shifts and operators more easily.

Effectiveness Through the Lens of Cost and ROI

Effectiveness in industrial cleaning ultimately converges on economics. A method that produces technically excellent results but undermines margins is not effective in practice. When laser cleaning and sandblasting are compared on a full-lifecycle basis, the picture becomes nuanced rather than binary.

Total Cost Structure Comparison

| Cost Element | Laser Cleaning | Sandblasting |

|---|---|---|

| Initial equipment | High | Low–medium |

| Consumables | Near zero | High (media) |

| Labor | Low–medium | High |

| Containment & cleanup | Minimal | Extensive |

| Waste disposal | Minimal | Significant |

| Long-term variability | Low | High |

Sandblasting’s apparent cost advantage is front-loaded. Laser cleaning’s advantage emerges over time as variable costs flatten. In high-utilization environments, this difference materially changes ROI.

Payback Behavior by Utilization

| Utilization Level | Laser Cleaning Payback | Sandblasting Payback |

|---|---|---|

| Low utilization | Slow | Immediate |

| Medium utilization | Moderate | Stable |

| High utilization | Fast | Margin erosion |

This explains why laser cleaning adoption accelerates in facilities with continuous or repetitive cleaning needs, while sandblasting remains prevalent in sporadic, project-based work.

Quality Outcomes and Downstream Effects

Effectiveness does not end when cleaning stops. The surface condition left behind influences coating adhesion, fatigue life, corrosion resistance, and rework rates.

Downstream Impact Comparison

| Outcome | Laser Cleaning | Sandblasting |

|---|---|---|

| Surface integrity | Preserved | Altered |

| Adhesion control | Tunable | Broad |

| Microstructural impact | Minimal | Possible |

| Rework probability | Low | Medium–high |

Laser cleaning can be tuned to achieve specific surface states without over-roughening. Sandblasting achieves roughness efficiently but with less control. In applications where downstream quality drives cost, laser cleaning is often more effective overall.

Industry-Specific Effectiveness: What Real Operations Choose

Effectiveness varies sharply by industry because priorities differ.

Automotive Manufacturing and Maintenance

| Priority | More Effective Method |

|---|---|

| Weld seam preparation | Laser cleaning |

| Spot paint removal | Laser cleaning |

| Full-body stripping | Sandblasting |

Automotive plants increasingly specify laser cleaning for precision tasks where repeatability and automation integration matter.

Aerospace and Defense

| Priority | More Effective Method |

|---|---|

| Substrate protection | Laser cleaning |

| Traceability | Laser cleaning |

| Large-area stripping | Sandblasting (limited use) |

Here, effectiveness is defined by risk reduction rather than speed. Laser cleaning often wins decisively.

Shipbuilding and Heavy Fabrication

| Priority | More Effective Method |

|---|---|

| Thick coatings, large areas | Sandblasting |

| Edge zones, weld prep | Laser cleaning |

| Environmental compliance | Laser cleaning (selective) |

Shipyards increasingly combine both methods, assigning each where it is most effective.

Automation and Consistency as Effectiveness Multipliers

Modern manufacturing places growing value on automation and digital control. This redefines effectiveness.

Automation Readiness Comparison

| Factor | Laser Cleaning | Sandblasting |

|---|---|---|

| Robotic integration | Strong | Weak |

| Process logging | Native | Limited |

| Repeatability | High | Low |

| Closed-loop control | Possible | Not feasible |

As production lines become more automated, laser cleaning’s effectiveness increases because it aligns with digital workflows. Sandblasting struggles to scale into these environments.

Environmental Effectiveness and Compliance Pressure

Effectiveness today includes the ability to operate within tightening environmental constraints.

Compliance-Oriented Comparison

| Aspect | Laser Cleaning | Sandblasting |

|---|---|---|

| Dust exposure | Very low | High |

| Secondary waste | Minimal | High |

| Permitting burden | Lower | Higher |

| Site flexibility | Greater | Restricted |

In regulated regions, laser cleaning’s effectiveness includes operational continuity—the ability to keep working without shutdowns or penalties.

The Case for Hybrid Processes

The most effective operations increasingly use hybrid workflows rather than choosing one method exclusively.

Hybrid Strategy Examples

| Task | Hybrid Approach |

|---|---|

| Heavy rust removal | Sandblast bulk + laser finish |

| Thick paint stripping | Mechanical pre-removal + laser detail |

| Large structures | Blasting for open areas, laser for critical zones |

Hybridization maximizes effectiveness by leveraging the strengths of both technologies while minimizing their limitations.

Common Misconceptions That Skew “Effectiveness” Judgments

Several myths distort comparisons:

- “Faster equals more effective.” Speed alone ignores damage, rework, and compliance costs.

- “Laser cleaning replaces sandblasting everywhere.” It does not—and does not need to.

- “Sandblasting is cheaper overall.” Only when utilization is low or precision is irrelevant.

Effective decision-making requires matching process capability to operational priority.

Final Answer: Is Laser Cleaning More Effective Than Sandblasting?

Laser cleaning is more effective than sandblasting when effectiveness is defined by precision, substrate protection, repeatability, automation readiness, and environmental control. Sandblasting remains more effective when effectiveness is defined by raw removal speed over large, low-value surfaces at minimal upfront cost.

In modern industrial practice, effectiveness is rarely absolute. The most effective solution is often selective use or a hybrid of both methods, applied where each delivers the most value.

A Practical, Candid Perspective

At BOGONG Machinery, we evaluate surface preparation challenges without bias toward a single technology. Our role is to help customers deploy laser cleaning where it truly outperforms sandblasting—and to integrate both when that yields the best result.

If you are deciding between laser cleaning and sandblasting, the right question is not “Which is better?” but “Which is more effective for my material, scale, and quality requirements?”

Talk to BOGONG Machinery to design a surface preparation solution that balances speed, precision, compliance, and long-term value—based on real effectiveness, not assumptions.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com