Pulse Laser Cleaning Machine VS Continuous Laser Cleaning Machine

When I first stepped into a metal shop in rural China, I saw two laser heads side by side. One pulsed in short bursts, the other glowed steadily. The difference wasn’t just visual — the results told a story of risk, precision, and compromise. That memory has stayed with me: choosing between pulsed and continuous laser cleaning is often choosing your “level of control vs. throughput.”

In this article, I don’t just want you to memorize pros and cons. I want you to feel the decision. To sense when a pulsed cleaner will save your parts, and when a continuous one will speed you through piles. Below is a comparative, grounded, honest analysis—with nuance, warnings, and real buyer wisdom.

What “Pulsed” and “Continuous” Really Mean in Practice

First, let’s anchor our mental model:

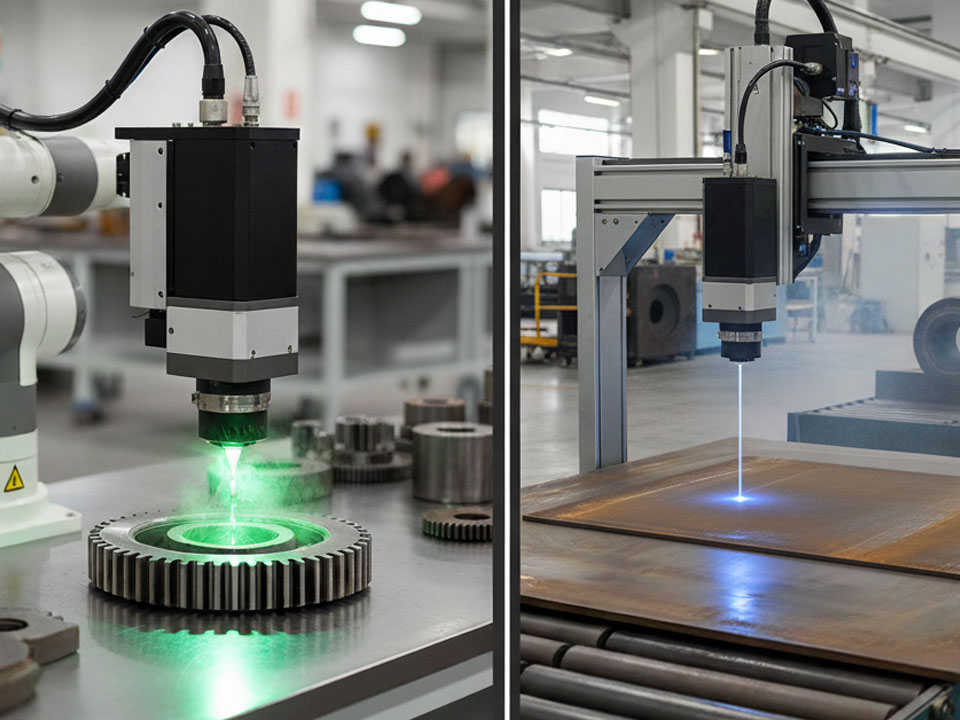

- A pulsed laser cleaning machine emits energy in discrete bursts (nanoseconds, microseconds, or modulated pulses). In each pulse, energy is concentrated momentarily, allowing contamination to vaporize or spall off with minimal heat diffusion.

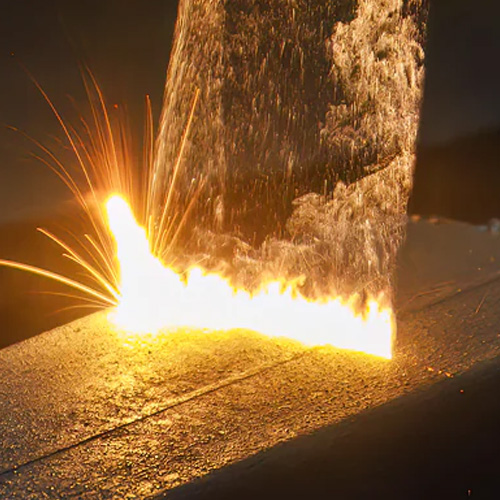

- A continuous (CW) laser cleaning machine emits a steady beam. The surface heats continuously; contaminants are removed gradually by heating, vaporization, or thermal expansion forces.

Because of that temporal distribution difference, everything downstream (heat, damage, drift, control) behaves differently.

Side-by-Side Comparison — The Real Tradeoffs

Here’s a detailed comparison of pulsed vs continuous in various dimensions—what I’ve learned from shops, experiments, and use cases.

| Thermal Damage & Safety Margin | Lower average heating. Short pulses give the substrate less time to soak heat. Less risk of micro-melting, discoloration, or warping. | Runs hotter as energy is continuous. If scanning speed or cooling fails, you risk substrate overheating, melt zones, or darkened surfaces. LaserFocusWorld notes that CW-cleaned surfaces often appear darker and rougher compared to pulsed cleaning. ([Laser Focus World][1]) |

| Cleaning Efficiency (same average power) | Often higher “useful cleaning per watt” in many cases. For example, a pulsed MOPA system cleaned dust on aluminum at 2.77 m²/h vs CW’s 0.36 m²/h at the same average power—roughly 7.7× better. ([Laser Focus World][1]) | To match performance, CW demands higher average power, but that comes with thermal risks. |

| Precision / Finesse | Excellent for fine control. You can tune pulse width, overlap, frequency to match contaminant layers. Ideal for delicate parts or multimaterial substrates. | Less granular control. You adjust power and scan speed, but you lose the temporal “rest periods” that help balance heat. |

| Throughput & Large-Area Work | Very capable for moderate areas, especially with higher repetition rates. But in massive flat surfaces, to compete you need good power or rapid scanners. | Strong point of CW. Continuous energy lets you sweep large surfaces steadily (if cooling and scanning are robust). |

| Complexity & Maintenance | More complex driver electronics, pulse shaping, optics, alignment demands. More calibration, upkeep. | Simpler in concept. Fewer pulsing electronics modules. But as power scales, control demands become harder. |

| Risk of Overexposure / Damage | Lower, because pulses allow cooling, mitigation, and less average thermal stress. | Higher. Continuous beam leaves less room for error; slower scans or misalignment quickly damage substrate. |

| Cost per Watt & Entry Price | Typically higher because pulse electronics, modulators, and precise optics are more expensive. | Lower in many basic systems, because of simpler design. |

| Best Application Domains | Molds, electronics, fine coatings, multi-layer films, heritage artifacts, precision parts | Structural steel, pipelines, ship hulls, large flat surfaces, heavy rust where substrate is robust |

How the Differences Play Out in Real Use Cases

Let me take you through scenarios I’ve seen (or advised), where the difference between pulsed and CW became real pain—or real opportunity.

Use Case 1: Mold & Tool Maintenance

You have mold cavities, fine surface details, very tight tolerances. You tried a CW cleaner—works, but you noticed faint discoloration along edges, slight blur on micro-features. After switching to a pulsed system and tuning pulses, the defects stopped. The pulsed approach gave you the margin to protect edges.

Use Case 2: Structural Rust Removal

You have large steel plates, thick rust, forgiving substrate. A CW cleaning machine ran effectively, peeling off layers fast, with acceptable substrate integrity. You care less about micro-surface quality and more about speed. In that context, CW wins.

Use Case 3: Mixed Parts Workshop

Your shop mixes delicate parts (tooling, electronics) and heavy frames. You opted for a hybrid or pulsed machine with enough power to push zones faster. For frames, you sweep quickly; for delicate parts, you dial down. It gave you flexibility without carrying two separate tools.

Decision Questions to Ask (So You Don’t Guess)

Here’s a mental checklist I wish more buyers carried before buy:

- What’s your substrate tolerance? If even small discoloration or structural changes hurt your parts, lean pulsed.

- What’s your worst-case ambient & cooling constraints? In hot, dusty shops, CW margin shrinks sharply. Pulsed gives more buffer.

- What surface sizes are you cleaning daily? If you do small-to-medium parts, pulsed is often enough. If you’re cleaning 10 m² slabs daily, CW may win on throughput if engineered right.

- How fine is your feature detail? Microgrooves, cavities, thin flanges demand finesse. Pulsed gives you more control.

- Which fails more gracefully? If cooling or optics degrade, will your machine reduce power or scrap parts? Pulsed systems generally degrade more forgivingly.

- How much maintenance and calibration bandwidth do you have? Pulsed systems demand more care. If your team is stretched, CW simplicity might appeal—but only if parts tolerate it.

- What’s your upgrade path? Maybe start pulsed, then add CW for bulk work. Or pick a system that supports both modes (if available).

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com