What is the cheapest way to remove rust?

Rust is not only cosmetic damage—it is a progressive electrochemical reaction that weakens structural integrity, reduces mechanical reliability, and accelerates long-term asset depreciation. Whether it appears on automotive components, construction machinery, factory equipment, pipelines, or simple hand tools, corrosion imposes financial loss if untreated. Many individuals and businesses ask a practical question: what is the cheapest way to remove rust? The answer depends not just on immediate cost, but on total lifecycle expense, labor time, surface damage risk, repeat treatment frequency, and long-term corrosion prevention effectiveness. Choosing the wrong low-cost method may result in higher downstream expenses. A technically sound decision requires understanding all rust removal options from both micro-scale DIY and large-scale industrial perspectives.

The cheapest way to remove rust for small-scale applications is manual mechanical removal using a wire brush, sandpaper, or household acidic solutions such as vinegar or citric acid, typically costing under 20–50 in materials. For medium-scale applications, abrasive blasting may cost 2–10 per square meter. For industrial and repeated use, laser rust removal—though higher upfront—can become the lowest long-term cost due to zero consumables, reduced labor, and minimal surface damage. The truly cheapest method depends on rust severity, scale, labor cost, and frequency of use.

Understanding rust chemistry is essential before selecting a removal strategy.

The Economic Framework of Rust Removal

To evaluate “cheapest,” we must define cost categories:

• Direct material cost

• Labor cost

• Equipment cost

• Surface damage repair cost

• Environmental disposal cost

• Long-term reoccurrence risk

A method with low material cost but high labor demand may not be cheapest overall.

Manual Mechanical Rust Removal

Manual removal is often the most economical method for small areas.

Tools Required

• Wire brush (5–15)

• Sandpaper (5–20)

• Steel wool (5–10)

• Hand grinder (optional 40–100)

Cost Analysis Table – Manual Method

| Factor | Value |

|---|---|

| Initial Cost | $10–$50 |

| Labor Intensity | High |

| Suitable Rust Level | Light to moderate |

| Surface Damage Risk | Moderate |

| Long-Term Protection | Requires coating |

Manual removal is extremely affordable but time-consuming. For small hand tools or localized corrosion, it remains the cheapest solution.

However, labor hours increase exponentially with surface area.

Household Chemical Methods

Acidic household solutions dissolve rust chemically.

Common agents include:

• White vinegar

• Citric acid

• Baking soda (mild)

• Phosphoric acid–based rust converters

Chemical Method Cost Table

| Chemical | Approx Cost | Rust Severity | Soak Time |

|---|---|---|---|

| Vinegar | $3–$10 | Light | 12–48 hrs |

| Citric Acid | $10–$25 | Moderate | 4–24 hrs |

| Rust Converter | $15–$40 | Moderate | 1–3 hrs |

Chemical removal is inexpensive but slower and limited to smaller components. Large industrial surfaces are impractical for soaking.

Abrasive Blasting

Sandblasting or media blasting is common for larger projects.

Cost Structure

• Media cost: 0.50–2 per kg

• Compressor electricity

• Operator labor

• Dust collection

Abrasive Blasting Cost per m²

| Project Size | Estimated Cost |

|---|---|

| Small Component | $50–$150 |

| Car Body | $800–$2,000 |

| Industrial Structure | $5–$15/m² |

Blasting is cost-effective for large surfaces but introduces surface roughness and potential warping.

Long-term costs include:

• Media replacement

• Waste disposal

• Equipment maintenance

Grinding & Power Tool Removal

Using angle grinders with flap discs accelerates removal.

• Disc cost: 3–8 each

• Grinder electricity minimal

• High labor intensity

Effective for heavy rust but damages base metal thickness.

Electrolytic Rust Removal

Electrolysis removes rust without abrasion.

Equipment Needed

• Power supply

• Washing soda

• Water container

• Sacrificial anode

Cost

Under $50 setup for DIY.

Limitations:

• Slow process

• Limited size capacity

Electrolysis is economical for small mechanical parts but unsuitable for large structures.

Laser Rust Removal – The Industrial Cost Perspective

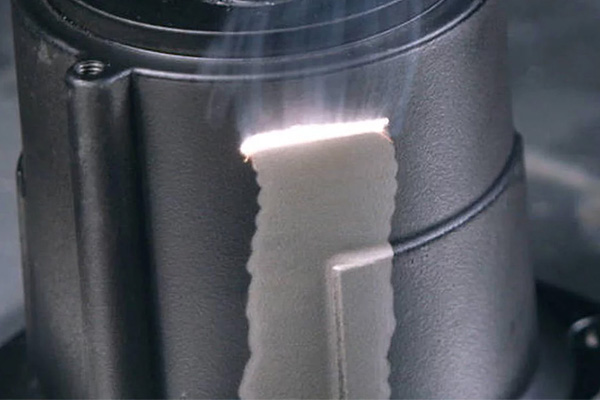

Fiber laser cleaning machines remove rust via high-energy photothermal ablation.

Upfront Cost

• Entry-level 100W: 6,000–9,000

• 1000W Industrial: 18,000–35,000

Operating Cost

• No consumables

• Electricity: ~$0.50/hour

• Minimal maintenance

Cost per Square Meter (Long-Term)

When amortized over 5 years:

| Annual Usage | Effective Cost per m² |

|---|---|

| 100 m²/year | High |

| 1,000 m²/year | Competitive |

| 5,000 m²/year | Lowest overall |

Laser cleaning becomes cheapest when:

• Frequent rust removal needed

• Labor cost high

• Surface preservation critical

Comparative Total Cost Over 3 Years (Medium Workshop Scenario)

| Method | Equipment Cost | Consumables | Labor | Total 3-Year Cost |

|---|---|---|---|---|

| Manual | $200 | $500 | $12,000 | ~$12,700 |

| Blasting | $5,000 | $9,000 | $18,000 | ~$32,000 |

| Laser (1000W) | $28,000 | $0 | $8,000 | ~$36,000 |

However, productivity differs significantly.

Laser reduces labor hours by 40–60%.

Surface Preservation Consideration

Cheapest immediate method may not be cheapest long-term if:

• Surface deformation occurs

• Material thickness reduced

• Recoating required frequently

Laser cleaning preserves base metal better than abrasive methods.

Cheapest Method by Application Type

Household Tools

Manual brushing + vinegar = cheapest

Automotive Surface Rust

Mechanical sanding + primer = economical

Heavy Machinery

Blasting for one-time job = moderate cost

Industrial Repeated Rust Removal

Laser = lowest long-term cost

Environmental & Compliance Cost Impact

Chemical disposal and abrasive dust create regulatory burdens.

Laser systems produce minimal waste.

Preventing Rust After Removal

True cost reduction comes from prevention.

Recommended coatings:

• Zinc-rich primers

• Epoxy coatings

• Powder coating

• Oil-based protectants

Prevention reduces repeated removal expense.

When Is DIY Truly Cheapest?

DIY is cheapest when:

• Rust is light

• Surface area small

• Labor cost ignored

• Structural damage absent

For business operations, labor cost cannot be ignored.

Economic Decision Matrix

| Condition | Recommended Cheapest Option |

|---|---|

| Small tool | Vinegar + brushing |

| Thin panel | Sanding |

| Large frame | Blasting |

| Factory production | Laser system |

Long-Term Financial Insight

The word “cheapest” must be defined carefully:

• Short-term cash outlay

• Long-term operational efficiency

• Asset lifespan

• Safety

A 20 vinegar solution may be cheapest for a garden tool. A30,000 laser may be cheapest for a manufacturing plant processing thousands of square meters annually.

Final Conclusion

The cheapest way to remove rust depends entirely on context. For small-scale and light corrosion, manual mechanical methods or simple household acids are undeniably the lowest upfront cost. For medium-scale restoration, abrasive blasting provides economical area coverage. For industrial, repeated, and labor-intensive applications, laser rust removal often becomes the most cost-efficient long-term solution despite higher initial investment.

Choosing correctly requires evaluating rust severity, surface area, labor cost, frequency of use, and desired surface preservation quality.

Let’s Find the Most Cost-Effective Rust Removal Strategy for You

Every rust problem is different. Whether you are working on small tools, vehicle restoration, or industrial equipment maintenance, selecting the right method determines your true cost savings.

At BOGONG Machinery, we specialize in industrial-grade laser rust removal systems designed to reduce labor, eliminate consumables, and maximize long-term profitability. If your operation involves recurring rust treatment, we can help you calculate ROI and identify whether laser technology will deliver the lowest total cost for your business.

Contact BOGONG Machinery today to discuss your application. Our engineering team will provide a tailored cost analysis and recommend the most economical and efficient solution for your rust removal needs.

Talk to Bogong Laser Cleaning Machines ExpertsGet a Quote or Customized Solution for Your Application

-

Whatsapp: +86-15665870861

-

Email: info@bogongcnc.com